Plasma processing apparatus including an isothermal processing zone

A technology of plasma and processing area, which is applied in semiconductor/solid-state device manufacturing, coating, gaseous chemical plating, etc., and can solve problems such as uneven substrate processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

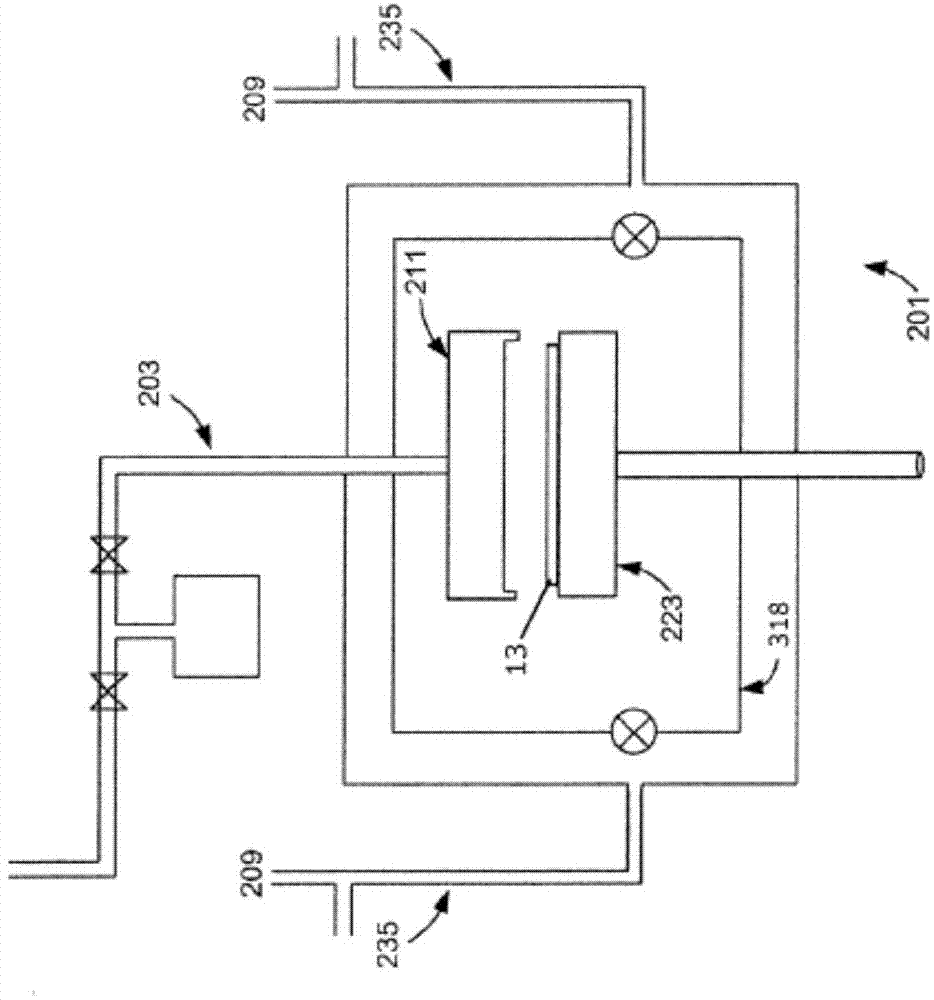

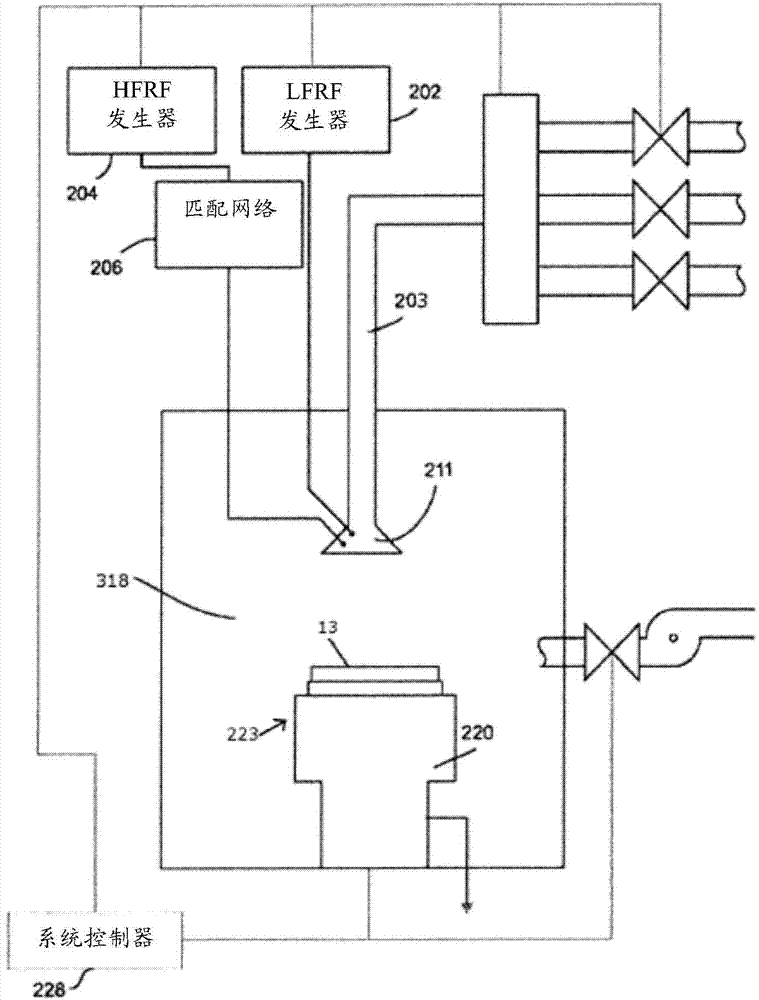

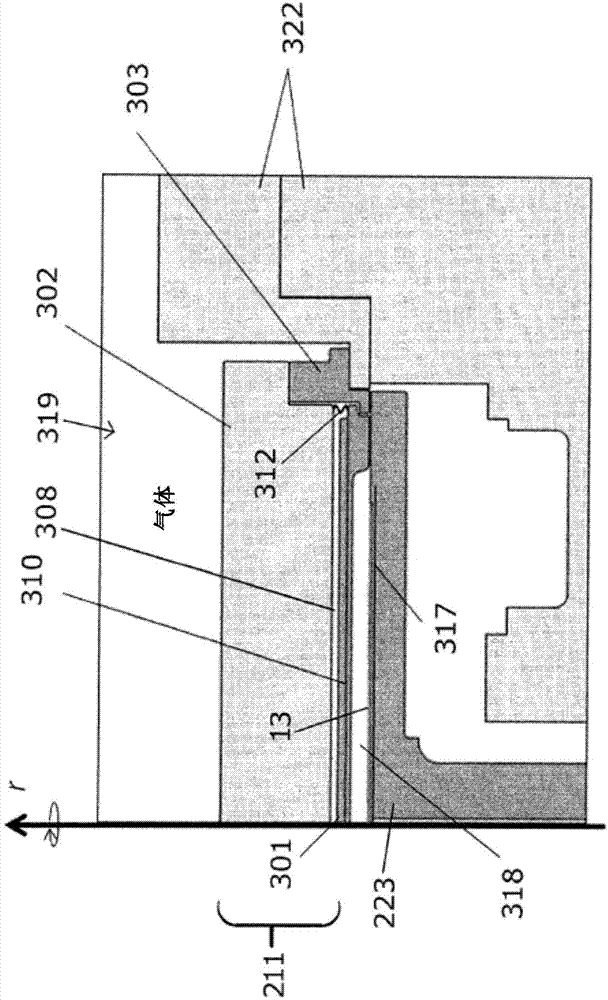

[0025] image 3 A cross-section of the chemical isolation chamber 319 is shown in more detail, including figure 1 and figure 2 The pedestal module 223 and the showerhead module 211, wherein the pedestal module 223 and the showerhead module 211 form a cavity 318 in which the semiconductor substrate is processed. The cavity 318 is formed between the showerhead module 211 and the base module 223, wherein the lower surface of the panel 301 of the showerhead module 211 forms the upper wall and the sidewall of the cavity 318, and the upper surface of the base module 223 forms the upper wall of the cavity 318. lower wall. An exemplary embodiment of a deposition apparatus including a dual chamber seal can be found in commonly assigned US Patent 7,737,035, which is incorporated herein by reference in its entirety.

[0026] The base module 223 includes a bottom RF electrode 317 on which the substrate 13 rests. Preferably, the bottom RF electrode 317 is grounded. During processing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com