Azilsartan pharmaceutical composition and preparation method thereof

A composition and medicine technology, applied in the field of pharmaceutical compositions containing azilsartan and its preparation, can solve problems such as poor stability and unsatisfactory drug dissolution, achieve simple production process, reduce equipment and plant investment, save money The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

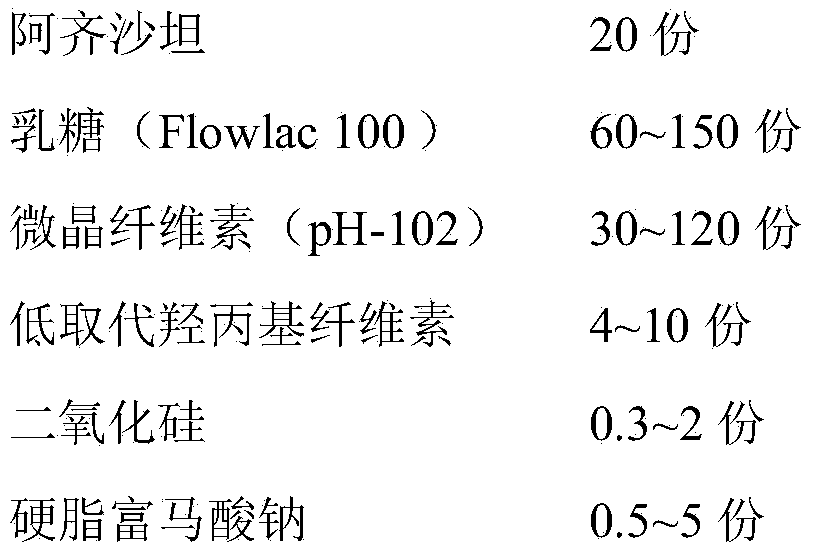

[0048] 1. Prescription

[0049]

[0050] 2. Preparation process

[0051] 1) Azilsartan is micronized, the particle size is controlled to be no more than 15 microns, weighed according to the prescription amount, and set aside;

[0052] 2) Dry lactose, microcrystalline cellulose, low-substituted hydroxypropyl cellulose, silicon dioxide and sodium stearyl fumarate in an oven at 80°C for 2 hours, sieve through 80 mesh, and set aside;

[0053] 3) Weigh the above-mentioned standby azilsartan, lactose, microcrystalline cellulose, low-substituted hydroxypropyl cellulose, silicon dioxide and sodium stearyl fumarate according to the prescription amount, mix them evenly, and press into tablets.

Embodiment 2

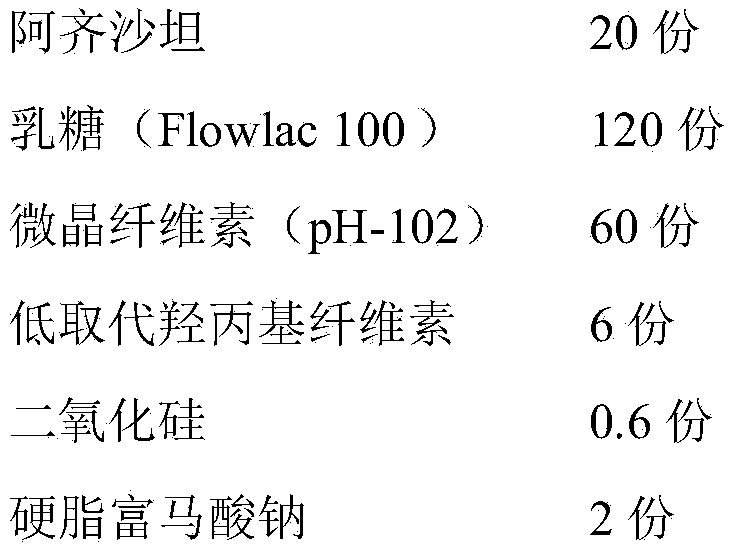

[0055] 1. Prescription

[0056]

[0057] 2. Preparation process

[0058] 1) Azilsartan is micronized, the particle size is controlled to be no more than 20 microns, weighed according to the prescription amount, and set aside;

[0059] 2) Dry lactose, microcrystalline cellulose, low-substituted hydroxypropyl cellulose, silicon dioxide, and sodium stearyl fumarate in an oven at 60°C for 3 hours, sieve through a 60-mesh sieve, and set aside;

[0060] 3) Weigh the above-mentioned standby azilsartan, lactose, microcrystalline cellulose, low-substituted hydroxypropyl cellulose, silicon dioxide and sodium stearyl fumarate according to the prescription amount, mix them evenly, and press into tablets.

Embodiment 3

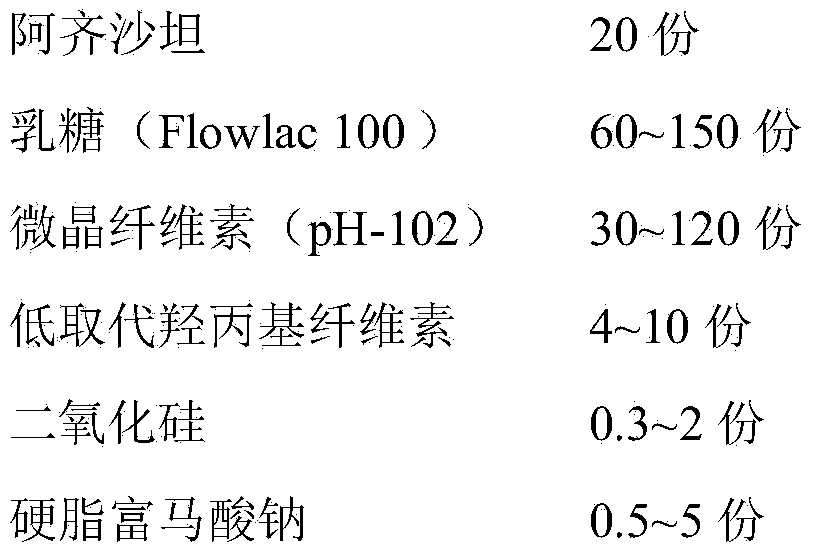

[0062] 1. Prescription

[0063]

[0064] 2. Preparation process

[0065] 1) Azilsartan is micronized, the particle size is controlled to be no more than 30 microns, weighed according to the prescription amount, and set aside;

[0066] 2) Dry lactose, microcrystalline cellulose, low-substituted hydroxypropyl cellulose, silicon dioxide and sodium stearyl fumarate in an oven at 70°C for 2 hours, sieve through 80 mesh, and set aside;

[0067] 3) Weigh the above-mentioned standby azilsartan, lactose, microcrystalline cellulose, low-substituted hydroxypropyl cellulose, silicon dioxide and sodium stearyl fumarate according to the prescription amount, mix them evenly, and press into tablets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap