A cleaning machine using an intelligent wired controller

A controller and washing machine technology, applied in the direction of liquid cleaning methods, chemical instruments and methods, cleaning methods and appliances, etc., can solve the problems of risk of loss of control, large impact of gun valves, waste of water, etc., to achieve high reliability Performance and stability, high control stability, water and electricity saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

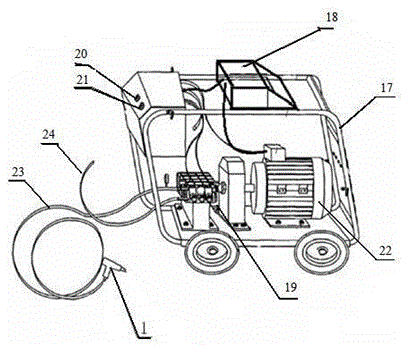

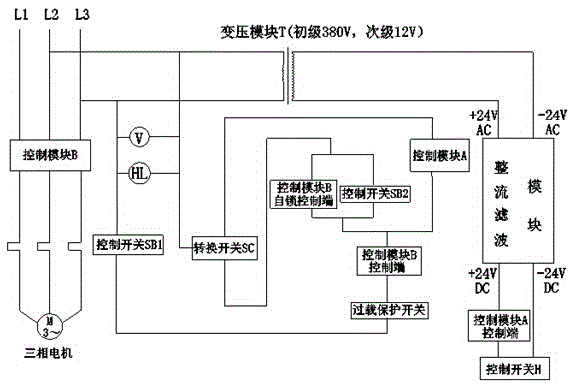

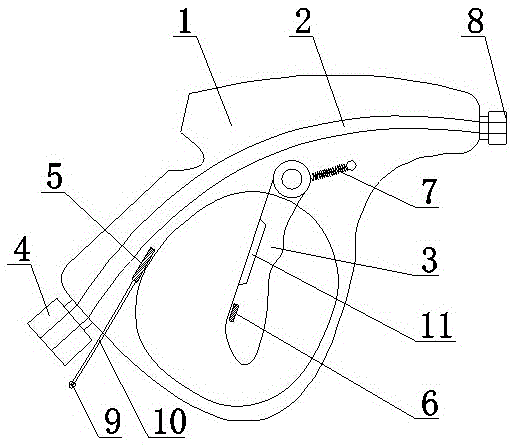

[0035] Such as figure 1 Shown, a kind of cleaning machine that adopts intelligent wired controller, it comprises three-phase motor 22, plunger pump 19 and high-pressure spray gun 1, high-pressure spray gun 1 is connected with the outlet end of plunger pump 19 through outlet pipe 23, plunger pump The water inlet end of 19 is connected with the water inlet pipe 24, and the power input of the plunger pump 19 is connected with the power output of the three-phase motor 22. The high-pressure spray gun 1 is provided with a control switch H5, and the control switch H5 can be controlled by a Hall switch. Realize that the outlet pipe 23 includes the outlet pipe core 15 and the outlet pipe wire 13, the spray gun water inlet port 4 on the high-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com