Fault detection mechanism for progressive die of motor core

A technology of error detection and progressive die, applied in molding tools, safety equipment, manufacturing tools, etc., can solve the problems of inadequate feeding, misfeeding of materials, errors in material thickness or width, etc., to improve technical quality and ensure smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

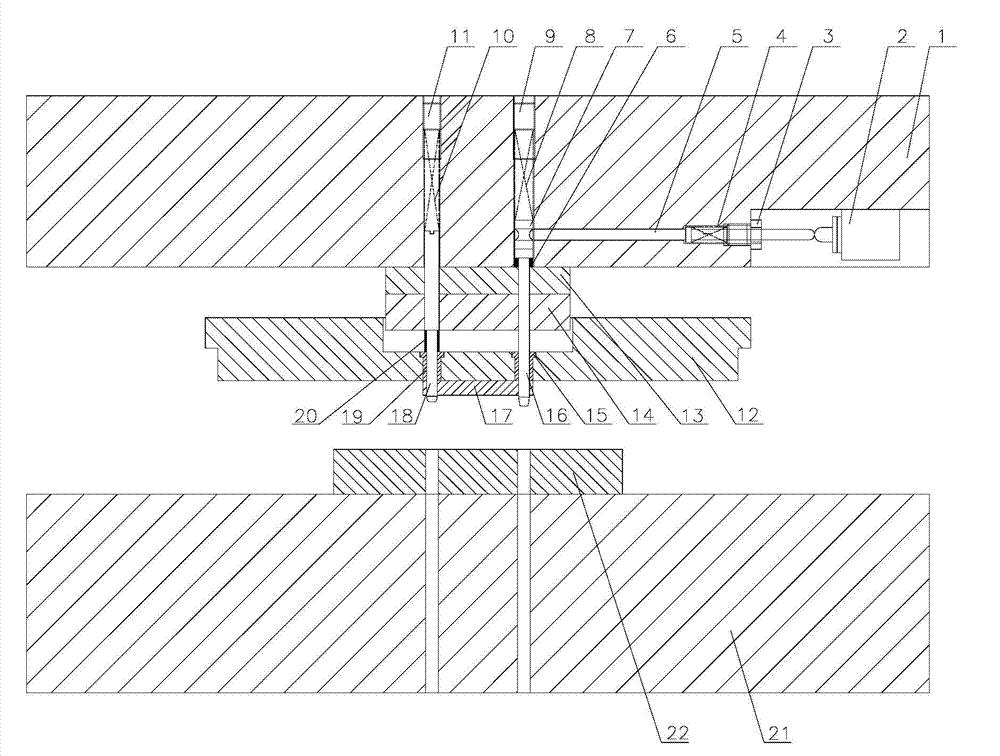

[0015] Further illustrate the present invention below in conjunction with accompanying drawing

[0016] Referring to the attached picture:

[0017] The motor iron core progressive die error detection mechanism of the present invention comprises the miniature stroke switch 2 that is connected with the machine tool controller, the error touch rod 5, the error slider 7, the error guide pin 16, and the described miniature stroke switch 2 is fixed On the upper mold base 1 equipped with guide pin 18; the trigger end of the micro travel switch 2 is in contact with the end of the micro travel switch 2 of the fault trip rod 5, and the ball head of the other end of the fault trip rod 5 The structure is in contact with the side slot of the slip slider 7 that slides along the first through hole of the upper die base 1; the upper end surface of the slip slider 7 passes through the first compression spring 8 and the first screw plug plugged in the top of the first through hole. 9 separated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com