Anchoring product prepared from fly ash ceramsite

A fly ash ceramsite and anchoring technology, which is applied in the field of anchoring materials, can solve the problems of low use efficiency of anchoring materials, achieve the effects of protecting resources and the environment, improving technical quality, and using a large amount of ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

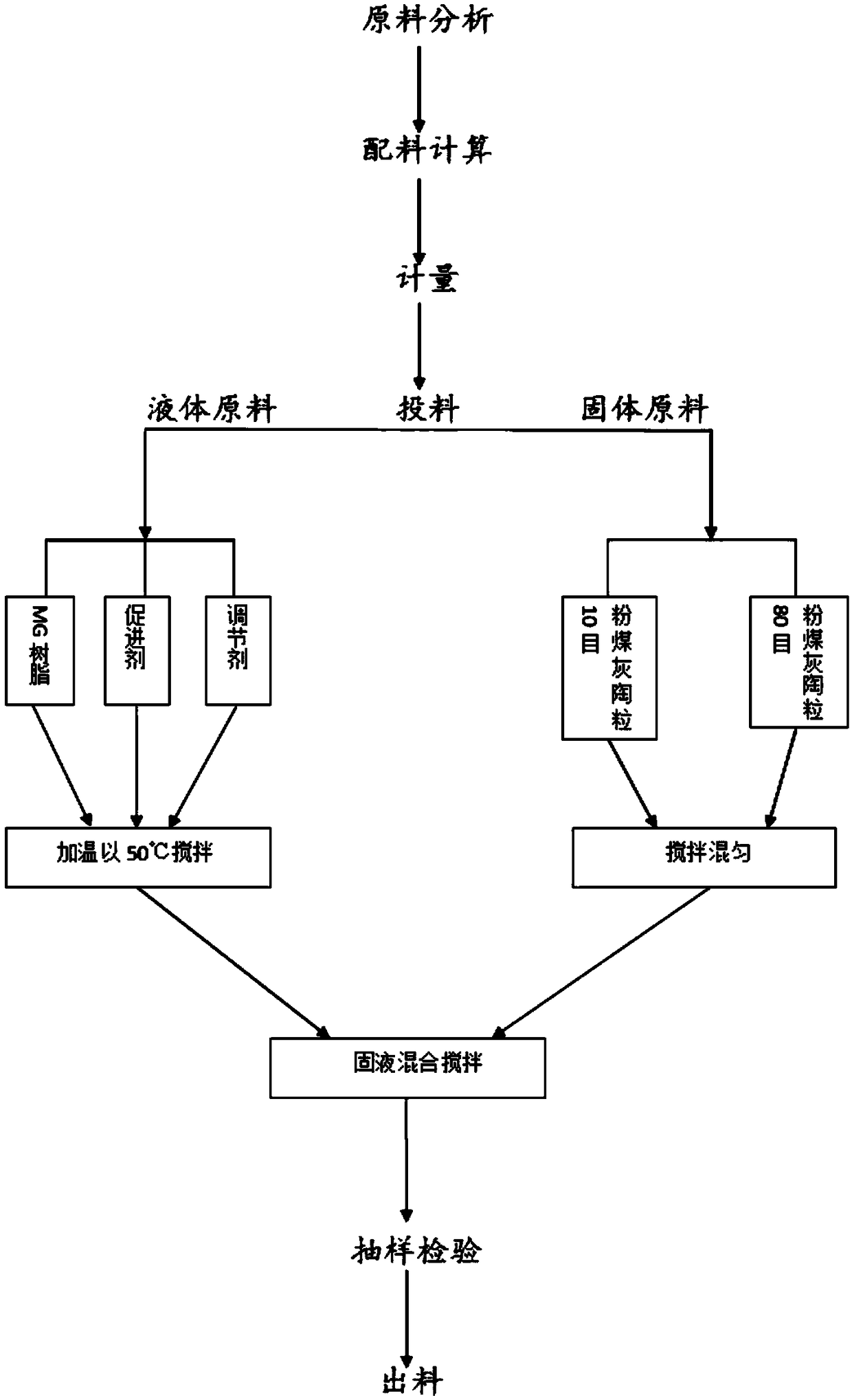

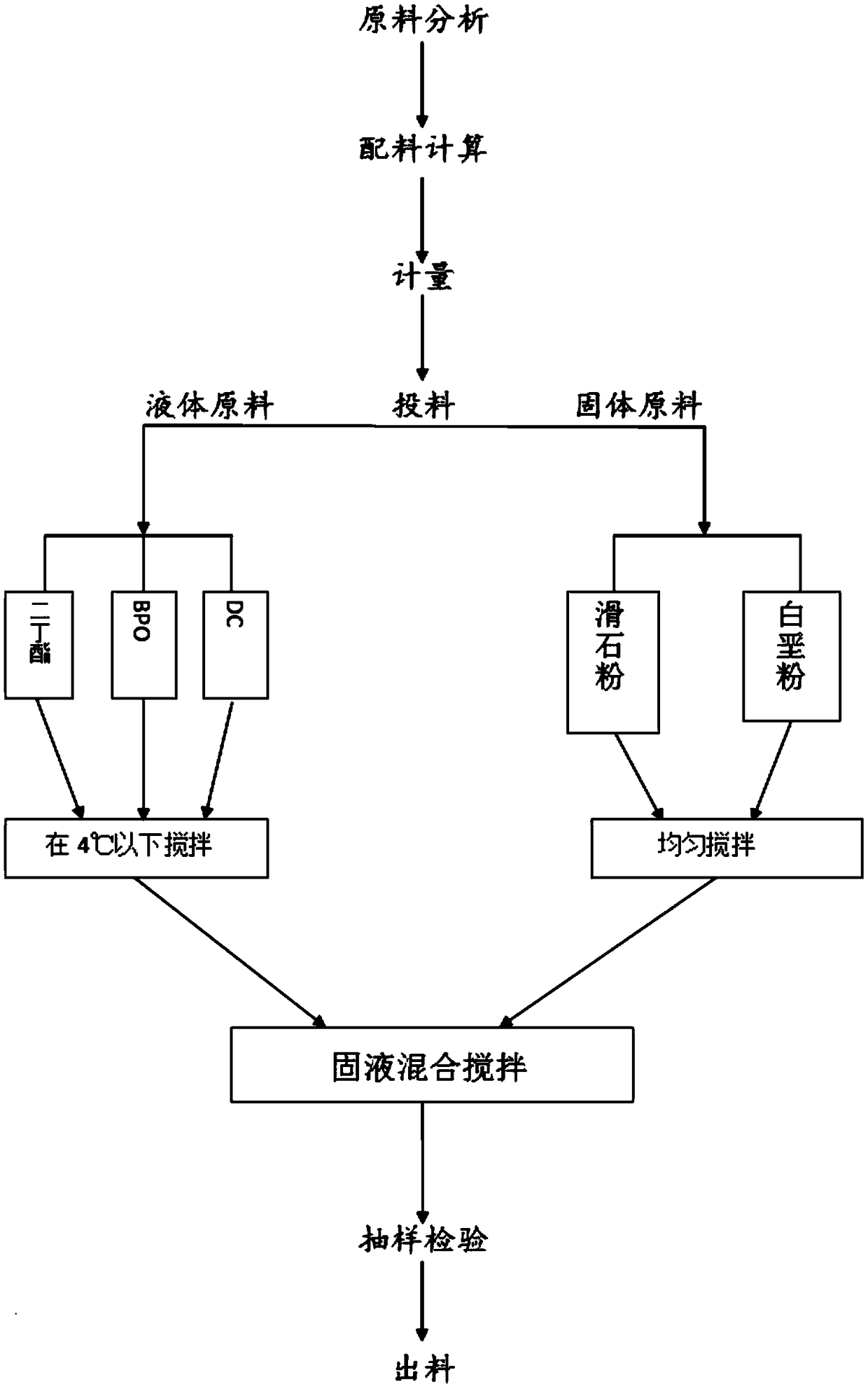

Method used

Image

Examples

Embodiment 1

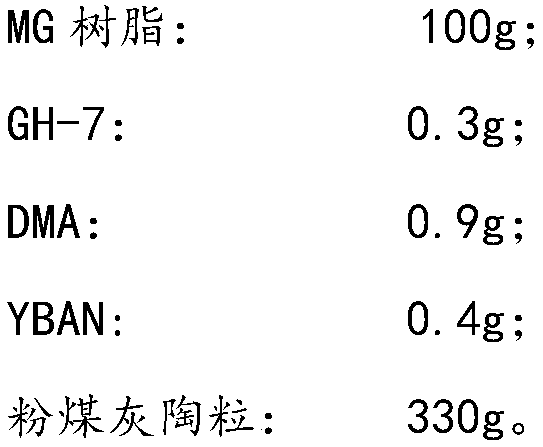

[0036] An anchoring product formulated from fly ash comprises component A and component B; wherein the ratio of component A to component B is 100:11. Wherein, the component A is composed of the following mass components:

[0037]

[0038] The B component consists of the following ingredients: (this formula is set as B1)

[0039]

[0040] The index requirements of each component are:

[0041] MG:

[0042] Acid value: 16-25mgKOH / g;

[0043] Solid content: 62-66%;

[0044] Gel time: 6-12min / 25℃;

[0045] Thermal stability: h≥24 at 80°C;

[0046] Compressive strength: 80-100mpa.

[0047] GH-7:

[0048] SiO 2 Content: >99.5%;

[0049] Apparent density: 0.03-0.05g / ml.

[0050] DMA:

[0051] Xylene content: >99.0%;

[0052] Toluidine content: <0.5%;

[0053]Freezing point of dry product: 1.8.

[0054] Fly ash ceramsite:

[0055] Fineness: 10-80 mesh;

[0056] Expansion coefficient: 1.5-3.5;

[0057] Particle density: 2300-2800kg / m 3 .

[0058] BPOs:

[0059]...

Embodiment 2

[0078] An anchoring product formulated from fly ash comprises component A and component B; wherein the ratio of component A to component B is 100:9. Wherein, the component A is composed of the following mass components:

[0079]

[0080]

[0081] The B component is made up of the following ingredients: (this formula is set as B2)

[0082]

[0083] Wherein the index requirement of each component is identical with each component index in embodiment 1.

[0084] The preparation method of the component A is: put the raw material MG resin into the container tank with stirring according to the proportion, start the agitator, and slowly add the regulator into the stirred resin while starting the agitator, and mix and stir for 30-40min , when the color is consistent, add accelerator to continue stirring, stop stirring after 30-40min, stand still for 30-60min until the bubbles disappear, the stirring speed of the agitator is 400f / min, and the temperature control during stirrin...

Embodiment 3

[0087] An anchoring product formulated from fly ash comprises component A and component B; wherein the ratio of component A to component B is 100:8. Wherein, the component A is composed of the following mass components:

[0088]

[0089] The B component uses the formula B1.

[0090] Wherein the index requirement of each component is identical with each component index in embodiment 1.

[0091] The preparation method of the component A is: put the raw material MG resin into the container tank with stirring according to the proportion, start the agitator, and slowly add the regulator into the stirred resin while starting the agitator, and mix and stir for 30-40min , when the color is consistent, add accelerator to continue stirring, stop stirring after 30-40min, stand still for 30-60min until the bubbles disappear, the stirring speed of the agitator is 400f / min, and the temperature control during stirring Within 50°C.

[0092] The preparation method of the component B is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com