Silver-ingot casting pipeline

A pipeline and silver ingot technology, applied in casting equipment, equipment for feeding molten metal into molds, metal processing equipment, etc., can solve the problems of silver paste solidification, uneconomical, and increased operational complexity, and achieve the goal of improving casting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

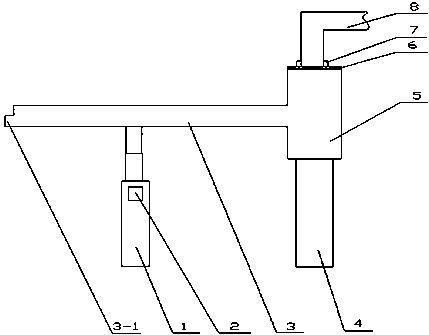

[0013] As shown in the accompanying drawings: a silver ingot casting pipeline, including a feed pipe 8, a support rod 4, and a branch pipe 3, the branch pipe 3 is a horizontal "T"-shaped pipe, the upper part of the "T" shape is located on the right side, and the "T" shape The lower side of the upper part of the "shape is a solid structure, and the upper side is connected with the lower part of the "T" shape. There is a threaded hole in the lower side of the upper part of the "T" shape, and the lower part of the lower part of the "T" shape is fixed with a The bracket 2 for adjusting the length; the upper end part of the support rod 4 is provided with threads corresponding to the inner threaded hole of the branch pipe 3;

[0014] A cover plate 6 is arranged at the upper port of the right part of the branch pipe 3, and a round hole is arranged in the center of the cover plate 6. The diameter of the round hole is the same as the outer diameter of the incoming material pipe, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com