Environment-friendly wood plate capable of absorbing harmful gas

A harmful gas and woodworking board technology, applied in wood processing equipment, manufacturing tools, wood layered products, etc., can solve indoor environmental pollution and other problems, and achieve the effect of strengthening the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will be combined with Figures 1 to 6 As well as the preferred embodiments, a kind of environmentally friendly woodworking board capable of absorbing harmful gases proposed by the present invention is described in more detail.

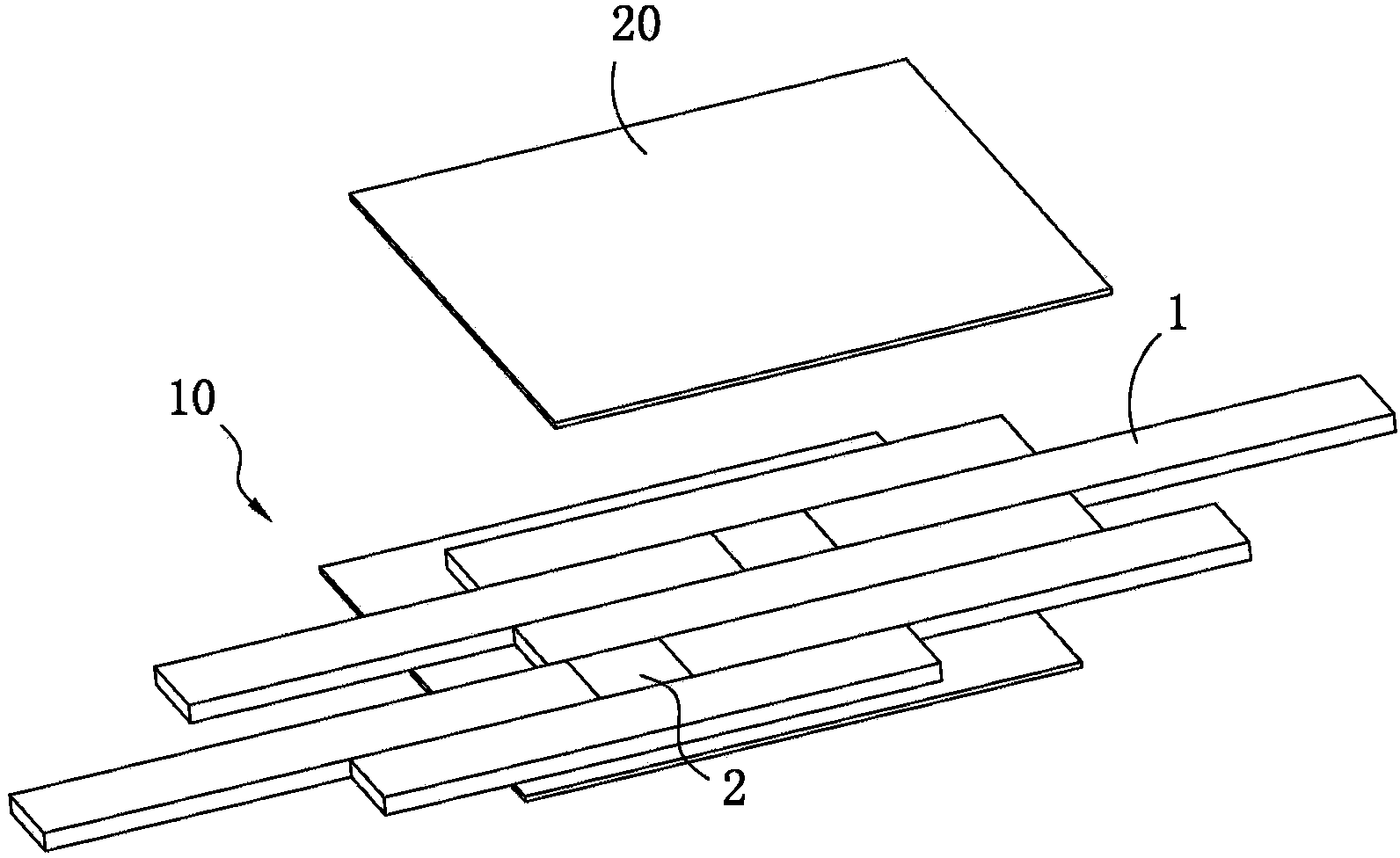

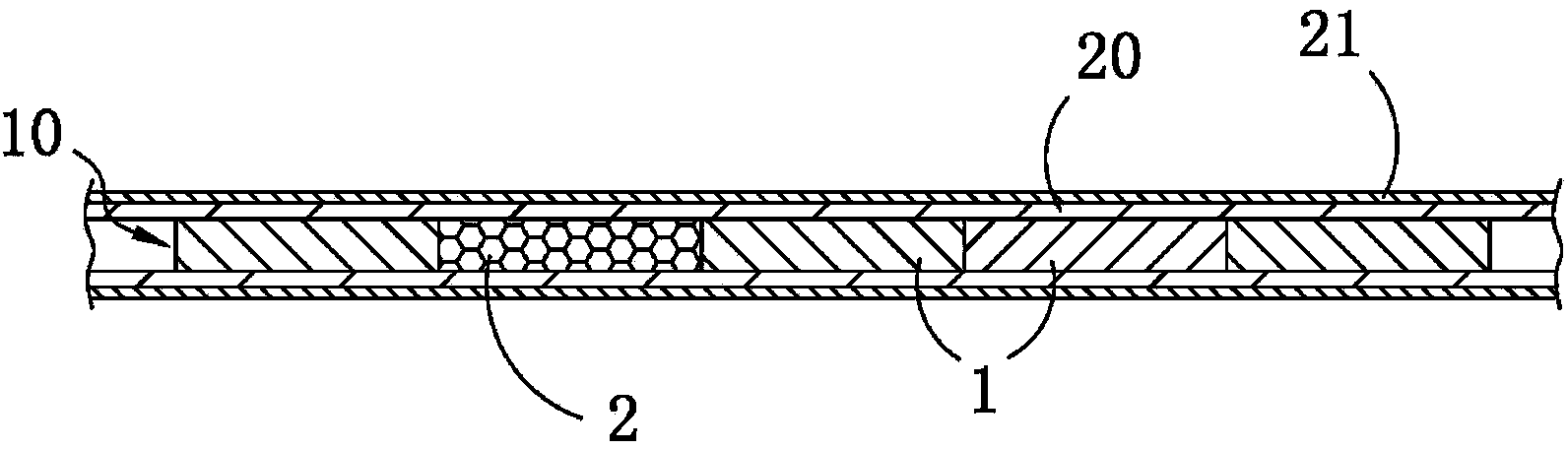

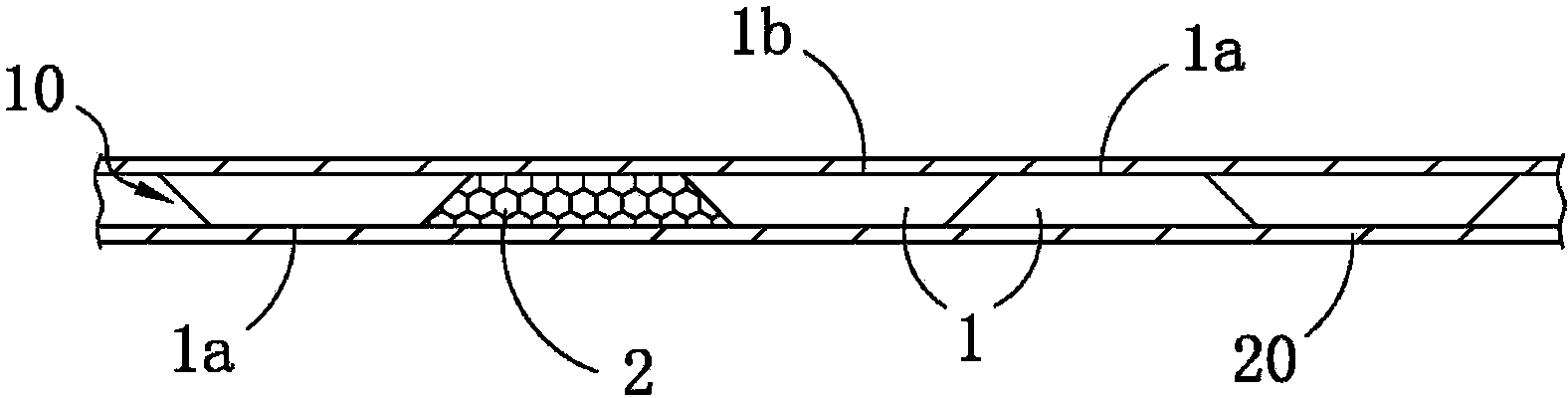

[0021] The invention provides an environmentally friendly woodworking board capable of absorbing harmful gases, such as figure 1 , 2 As shown, it includes a core board 10 and a veneer 20, and the two veneers 20 are respectively pasted on the two sides of the core board 10. The strips 1 are connected end to end to form a longitudinal strip group, and several longitudinal strip groups are spliced horizontally to form the core board 10, wherein the joints of the strips 1 in each longitudinal strip group that are horizontally spliced are all misplaced, Prevent the joints of the wooden strips 1 in the different longitudinal wooden strip groups from being on the same cross section to affect the stress intensity of the wood board of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com