Steel wire mesh frame polyethylene composite tube external layer sizing sleeve

A technology for polyethylene composite pipes and composite pipes is applied in the field of pipe forming equipment to achieve the effects of low manufacturing cost, convenient installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the drawings and implementation process.

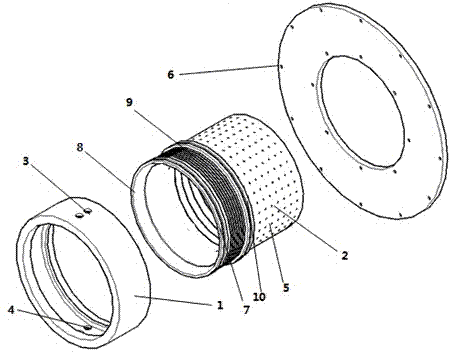

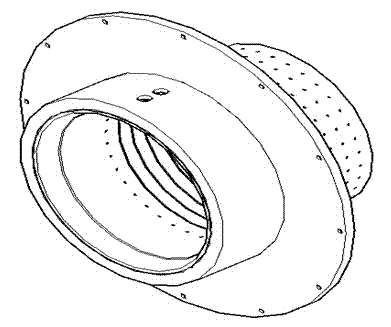

[0014] figure 1 Explain the basic composition of the sizing sleeve shell. The water ring 1 of the sizing sleeve and the inner core 2 of the sizing sleeve are inlaid in one body, and are connected with the vacuum sizing box by bolts through the bolt connection hole 6, and the water inlet hole 3 is connected with the cooling circulating water equipment of the external equipment. There is a cooling water chamber between the ring 1 and the inner core 2, so that the water chamber is filled with cooling water to cool the front section of the inner core of the sizing sleeve. At the same time, there is an annular groove at the front section of the inner core to increase the cooling area of the inner core of the sizing sleeve by the cooling water. Drainage is carried out through the drainage hole 4, so that the cooling water in the water chamber is circulated. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com