Printing method of single thin-paper digital printing machine

A printing method and printing machine technology, applied in printing, printing devices, etc., can solve the problems of thin paper adsorption, poor transmission stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

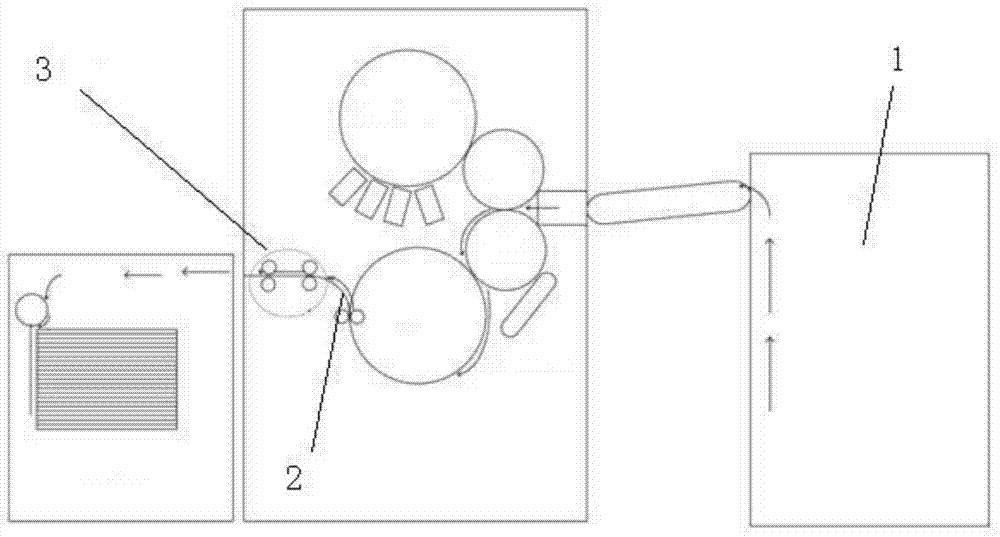

[0029] Single-fed thin paper digital printing machine includes paper input tray 1, suction cup, suction nozzle, suction pipe, paper path guide rail 2, and paper output tray 3. The paper is placed in the input tray 1, and the paper is sucked into the printing machine through the suction cup , and then reach the paper path guide rail 2 through the suction nozzle and suction pipe, and then output from the paper output tray 3.

[0030] Before thin paper printing, it is necessary to debug the computer. The first step is to use the ink adjustment system to adjust the spot color ink that meets the printing requirements; the second step is to put the spot color ink on the machine, and complete the specific replacement, implement color, density, conductivity In the third step, since the equipment can only print 64 grams of paper at the minimum, that is, the system value is 0.07mm, set it at 0.07mm, turn off the thick paper mode, test and check the double-sheet control, and check and adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com