Lifting electromagnet control method and system

A lifting electromagnet and control method technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of high reliability requirements, low precision of voltage and current control, large weight and volume, etc., to meet the requirements of high efficiency Operating requirements, improving demagnetization and demagnetization efficiency, and reducing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

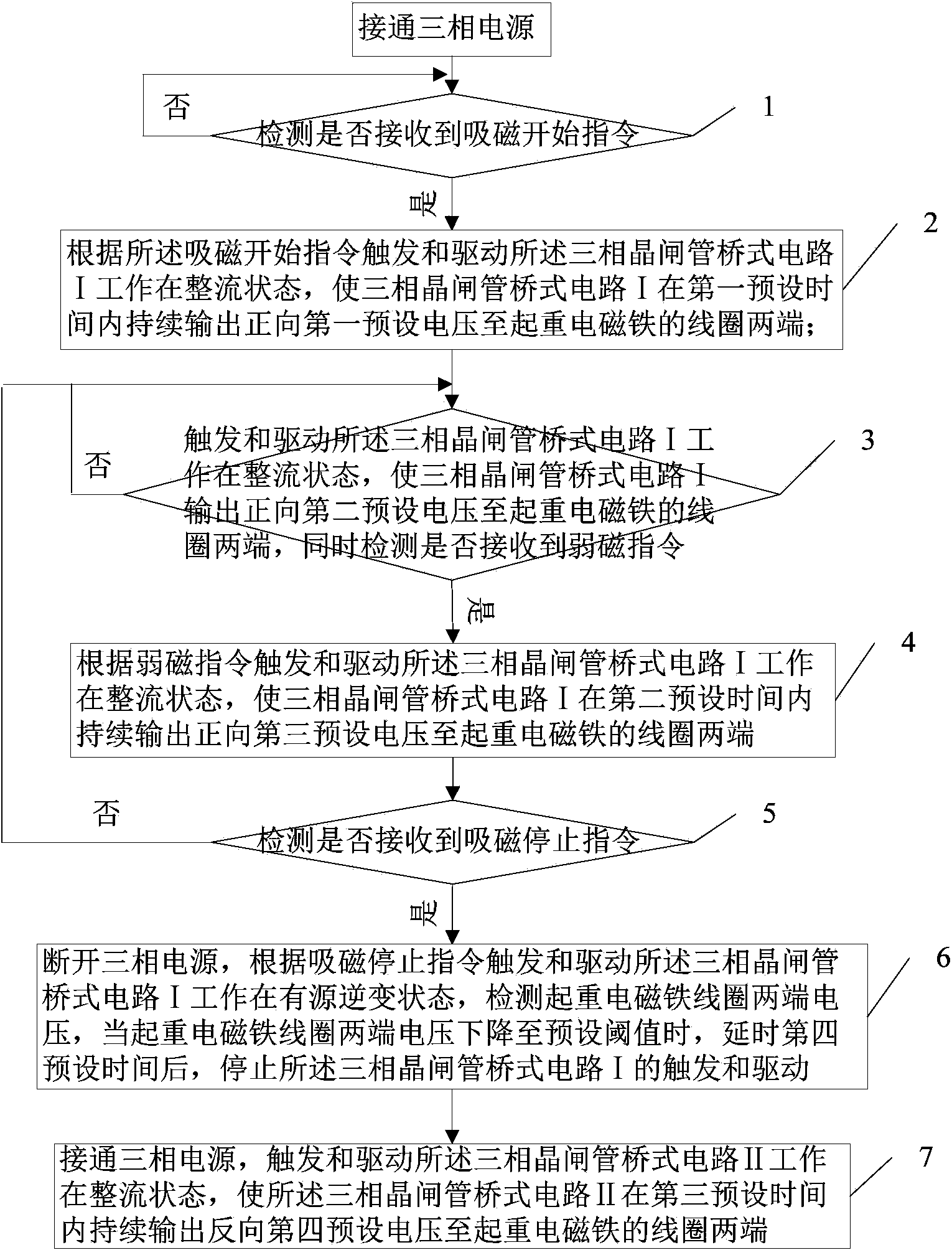

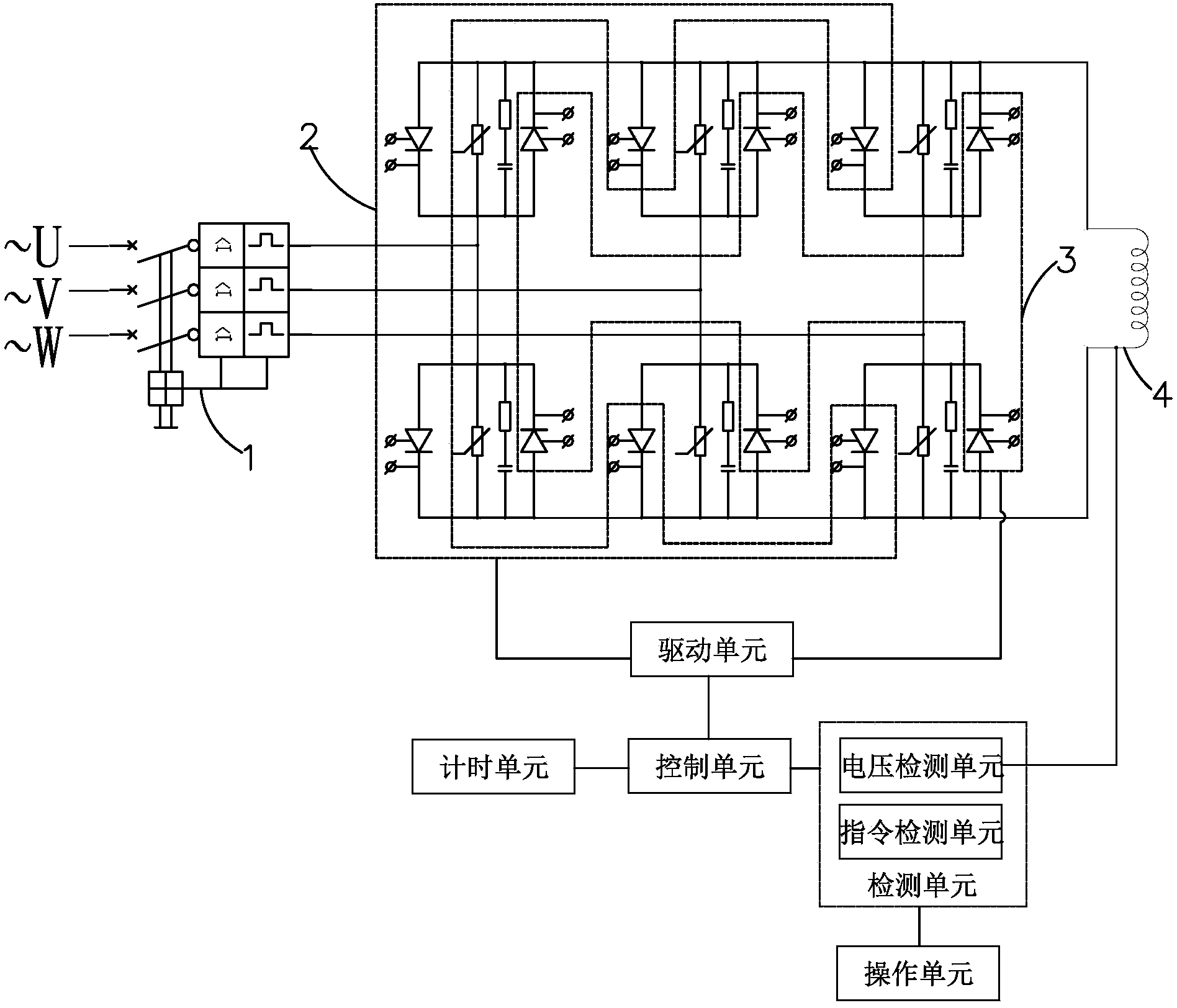

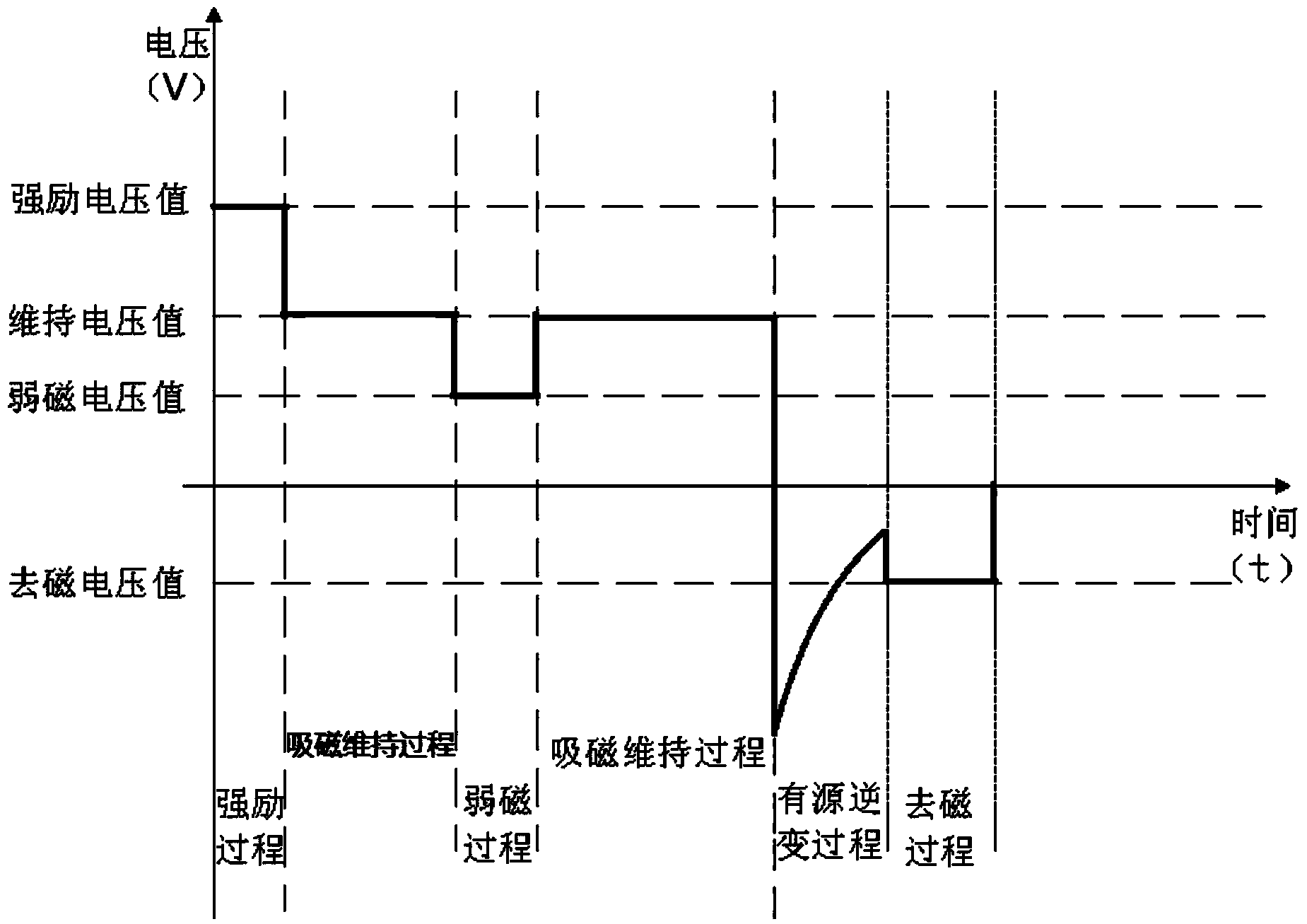

[0034] Such as figure 1 and figure 2 A lifting electromagnet control method is shown, the coil of the lifting electromagnet 4 is connected to the three-phase power supply through a three-phase thyristor parallel circuit; the thyristor three-phase parallel circuit includes a three-phase thyristor bridge circuit I3 and Three-phase thyristor bridge circuit II2; the control method includes the following steps:

[0035] Step 1: Detect whether the magnetic suction start command is received, if yes, execute step 2, otherwise return to step 1;

[0036] Step 2: Trigger and drive the three-phase thyristor bridge circuit I3 to work in the rectification state according to the magnetic attraction start command, so that the three-phase thyristor bridge circuit I3 continuously outputs the first preset forward direction within the first preset time Voltage to both ends of the coil of the lifting electromagnet 4; the first preset voltage is 80% to 130% of the rated voltage of the lifting el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com