Petroleum wastewater treatment machine used for improve filtering layer replacing efficiency

A sewage treatment and filter layer technology, applied in the mechanical field, can solve the problems of inability to filter, prolong the filter cycle, and difficult to disassemble, etc., and achieve the effect of improving efficiency and shortening the filter cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

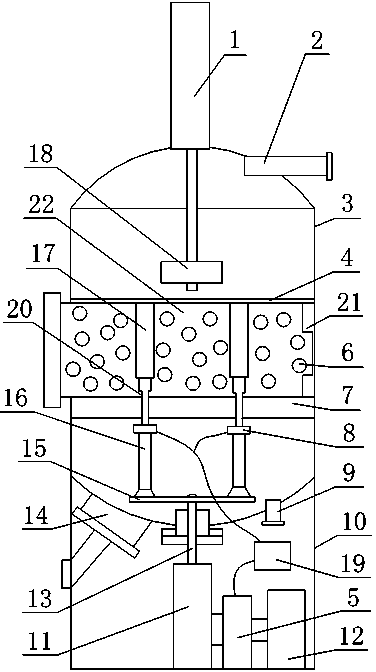

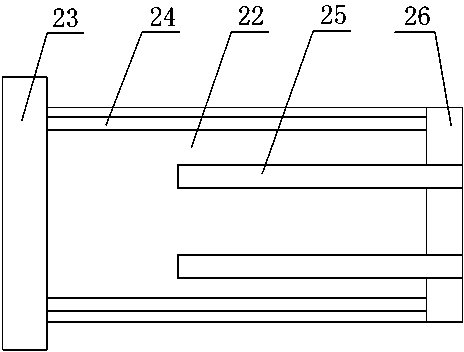

[0015] Such as figure 1 , figure 2 As shown, the petroleum sewage treatment machine for improving the replacement efficiency of the filter layer includes an outer cylinder 10 with a hollow interior. The top of the outer cylinder 10 is provided with a hollow tank body 3, and the bottom end of the tank body 3 is fixed on the top of the outer cylinder 10. Above, the tank body 3 is provided with a one-way filter disc 4 and a pressure plate 7, the one-way filter disc 4 is arranged directly above the pressure plate 7, and the outer wall of the one-way filter disc 4 is seamlessly connected with the inner wall of the tank body 3, and the pressure The outer wall of the plate 7 is in seamless contact with the inner wall of the tank body 3, and the pressure plate 7 can move vertically along the outer wall of the tank body 3, and the outer wall of the tank body 3 is provided with a loading and unloading port between the one-way filter plate 4 and the pressure plate 7 , the loading and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com