Coloring mold and coloring method for color stripe optical fiber

A mold and optical fiber technology, which is applied in the coloring mold and coloring field of color stripe optical fiber, can solve the problems of non-compliance with low-carbon environmental protection, toxic and harmful substances, and large amount of optical fiber ink, so as to save ink cost without affecting identification and ink consumption. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

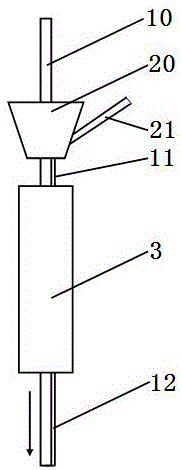

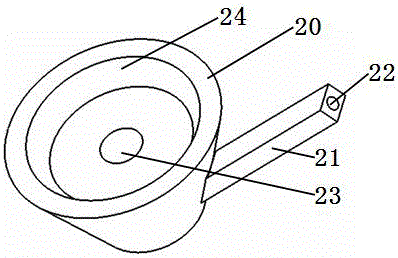

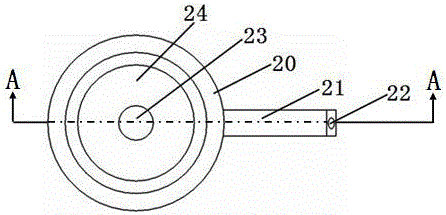

[0019] please see Figure 1 to Figure 5 , the coloring mold of color stripe optical fiber, it has the mold body 20 of conical shape, has the fiber hole 23 that penetrates up and down in the axial direction of mold body, it is characterized in that the outer surface of mold body side protrudes outwards an ink inlet device 21, The center of the ink-feeding device has an ink-feeding hole 22, and the ink-feeding hole communicates with the fiber-passing hole. Yes, the top of the mold body is a frustum-shaped large section, the mold body top has a concave groove 24, and there is an arc-shaped color bar groove 25 from the bottom of the junction of the fiber hole and the ink hole to the bottom of the mold body. The shape and color stripe groove communicates with the fiber hole, and the outer arc diameter of the curved color stripe groove is larger than the diameter of the fiber hole; the mold body and the ink feeding device are connected as a whole.

[0020] Furthermore, the above-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com