Cooling device for alloy profile

A technology for cooling devices and alloy profiles, applied in the direction of furnace types, furnaces, heat treatment equipment, etc., can solve the problems affecting the appearance and quality of profiles, long natural cooling time, pits and cracks in profiles, etc. It is easy to promote and simple in structure , the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

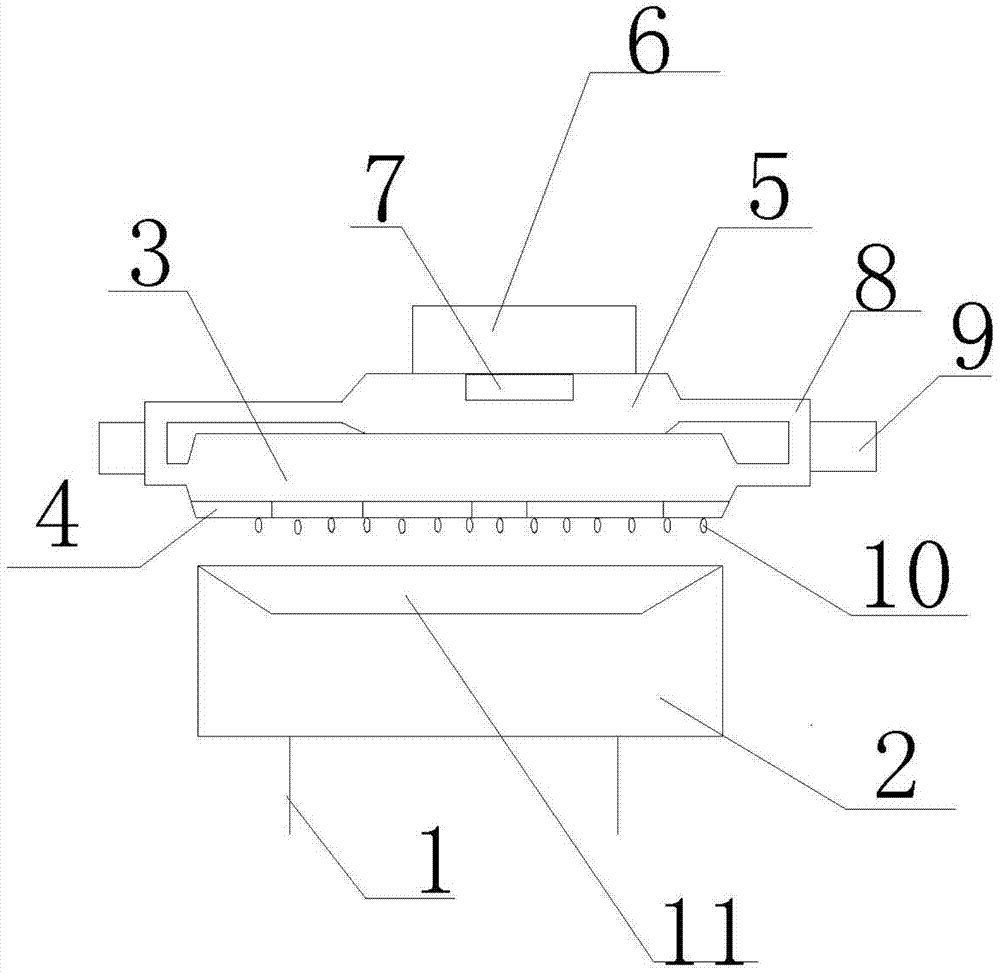

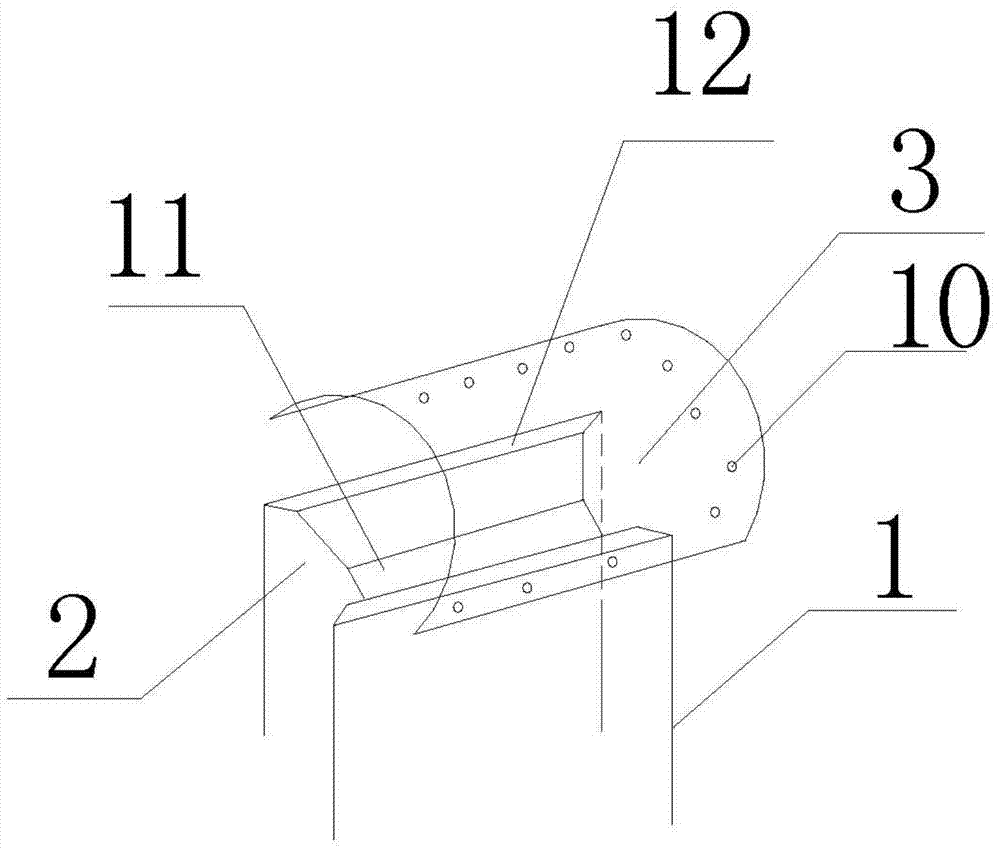

[0015] Such as figure 1 figure 2 As shown, a cooling device for alloy profiles, including a support frame 1, the support frame 1 is provided with a stage 2, the top of the stage 2 is provided with a cooling air channel 3, the cooling air channel 3 is provided with a number of sets of adjustment switches 4, an atomization box 5 is provided above the cooling air passage 3, a water tank 6 is provided above the atomization box 5, and a high-pressure atomization device is installed in the atomization box 5 7. The two ends of the atomization box 5 and the cooling air channel 3 are connected by a pipe 8, and a fan 9 is installed in the pipe 8, and the power of the fan 9 is 500w-2000w. The cooling device is simple in structure, reasonable in design, easy to popularize, and has good cooling effect. It changes the traditional alloy profile cooling method and adopts a new air channel cooling, which avoids pitting on the surface of the alloy profi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com