Motorcycle engine gas distribution mechanism and motorcycle engine

A valve train, engine technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of low engine power and torque, inability to achieve timing gas distribution, poor performance, etc., to improve power and torque, improve Inflatable efficiency, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

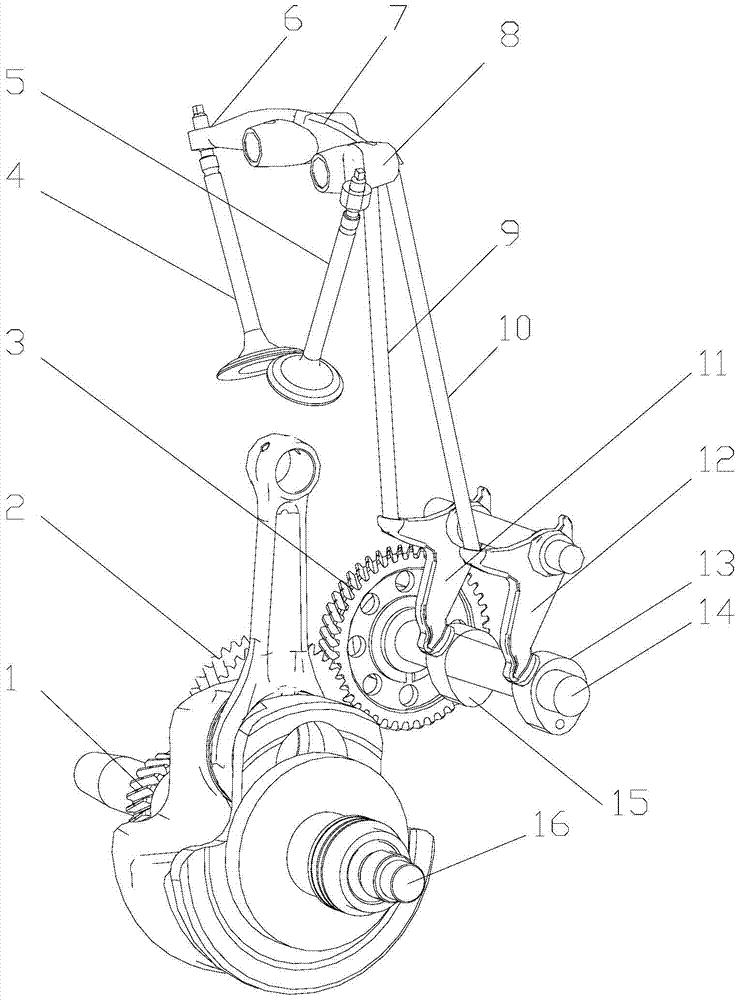

[0018] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure, the motorcycle engine gas distribution mechanism of the present embodiment includes an intake valve 4, an exhaust valve 5 and a camshaft for driving the intake valve 4 and the exhaust valve 5 to open 14. The intake valve 4 and the exhaust valve 5 are driven by different cams. In the existing motorcycle engine, the intake and exhaust cams 13 share the same cam drive. In this case, due to the profile of the intake and exhaust cams 13 The lines should be different, so the 13-type lines of the intake and exhaust cams either cannot meet the design requirements, or one of the cam lines is sacrificed, causing the engine to fail to achieve the expected timing gas distribution, while the motorcycle engine gas distribution system of the present invention mechanism, the intake valve 4 and the exhaust valve 5 are driven by different cams, so that designers can design the corresponding ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com