gear pump

A gear pump, driving gear technology, applied in the direction of pumps, pump components, rotary piston pumps, etc., can solve the problems of increased friction, difficult to accurately control the pressing force on the end face of the gear, and increased leakage, so as to reduce the leakage of the end face. , the use of a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the examples and the accompanying drawings, but the implementation of the present invention is not limited thereto.

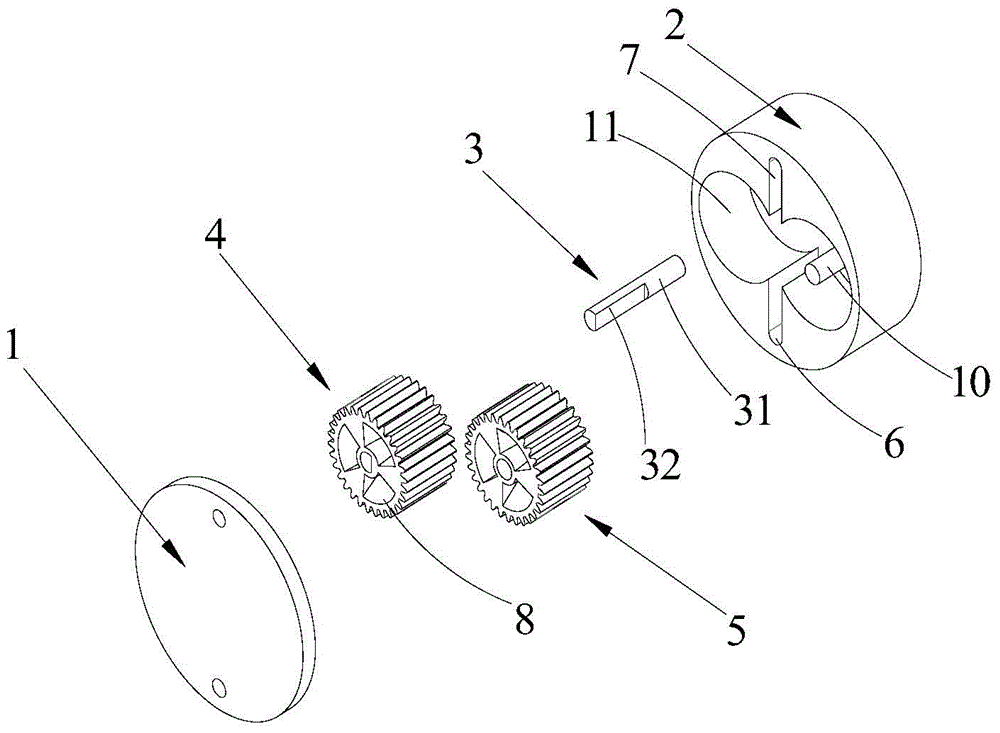

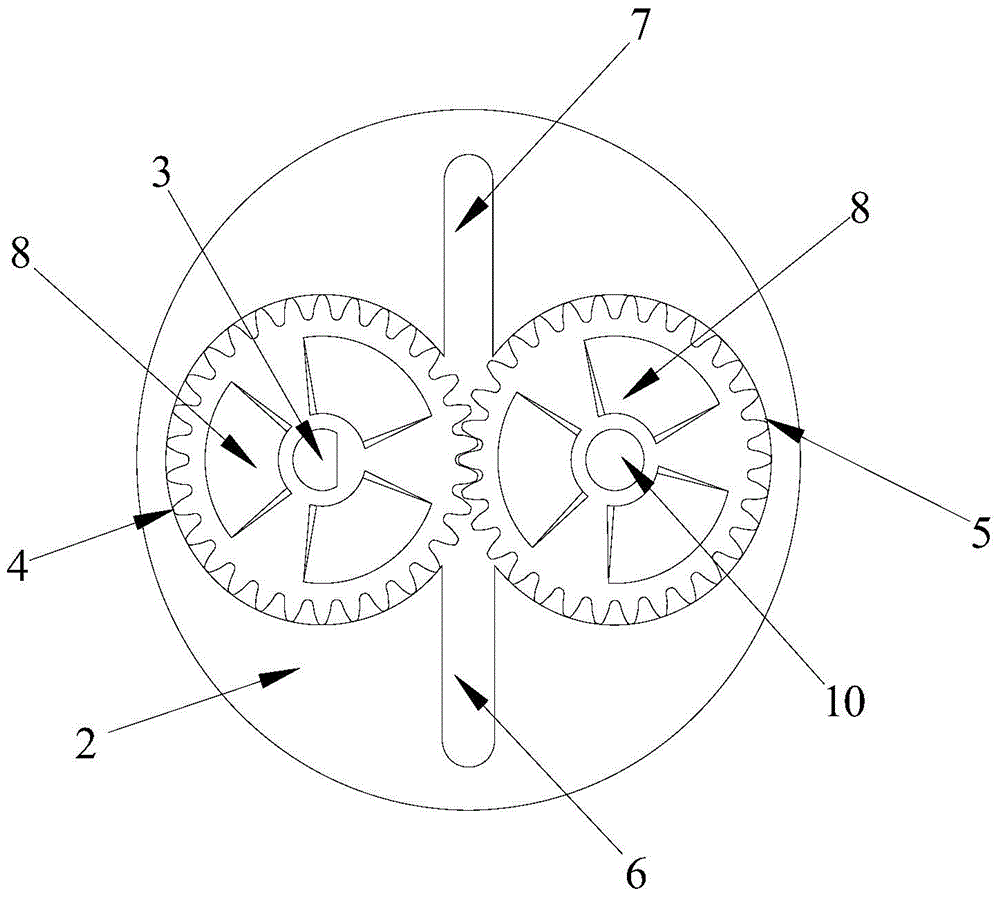

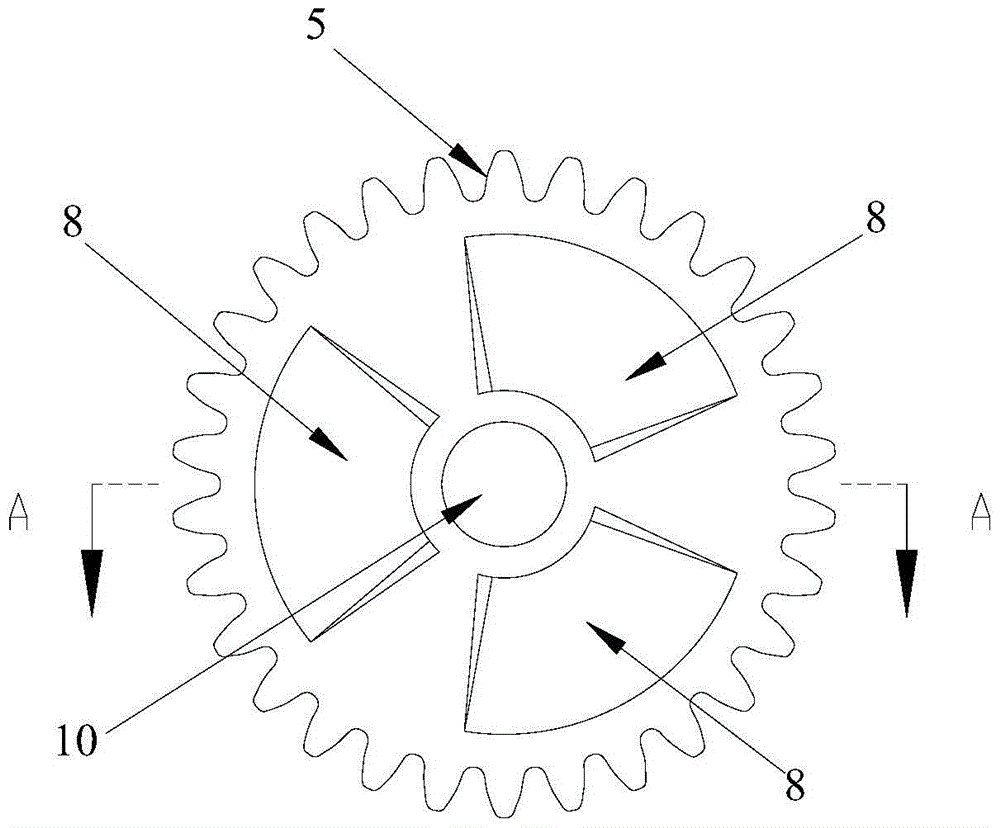

[0031] like Figures 1 to 4 As shown, the gear pump provided by the present invention includes an end cover plate 1, a rear cover 2, a drive shaft 3, and a driving gear 4 and a driven gear 5 that mesh with each other. The driving gear 4 is installed on the drive shaft 3, and the rear cover 2 A fixed shaft 10 is arranged on the top, and the driven gear 5 is installed on the fixed shaft 10. The back cover 2 is also provided with a suction port 6 and a discharge port 7. The back cover 2 cooperates with the end cover plate 1 to form a closed space, and the drive gear 4 and The driven gears 5 are all arranged in the closed space, and at least one end surface of the driving gear 4 and the driven gear 5 is provided with a groove 8, and lubricating grease is stored in the groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com