Double-layer heat transfer oil heating box

A heating box and heat-conducting oil technology, which is applied to heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems that the upper and lower heating boxes cannot be realized, the temperature of the heat-conducting oil can be adjusted to each other, and accurate temperature control cannot be realized. , to achieve the effect of improving heating efficiency, production safety, and accurate temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

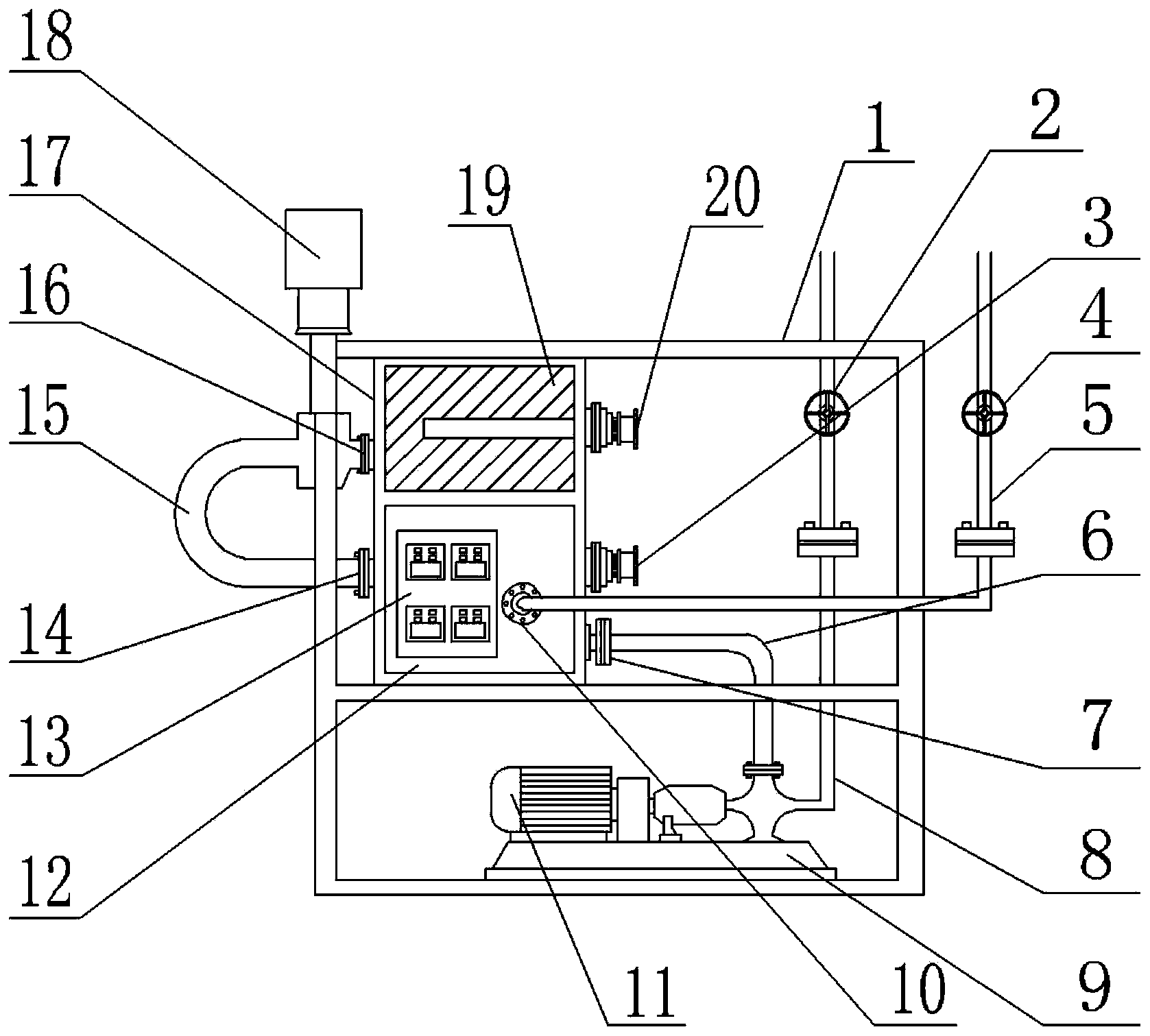

[0014] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

[0015] Such as figure 1 A double-layer heat conduction oil heating box is shown, including a main box frame 1, a heating box 17 and a hot oil pump 11, the heating box 17 is installed on the main box frame 1, and a hot oil pump is provided at the bottom of the box main frame 1 The base 9 and the thermal oil pump 11 are installed on the thermal oil pump base 9. The heating box 17 includes an upper box body 19 and a lower box body 12. The upper box body 19 and the lower box body 12 are connected by a U-shaped oil pipe 15. The upper box body 19 There is a No. 1 heater 20 inside, a No. 2 heater 3 is installed in the lower box 12, a No. 3 oil outlet 7 is provided on one side of the lower box 12, and one end of the thermal oil pump 11 is connected to the No. 3 outlet through the No. 3 oil delivery pipe 6. The oil port 7 is connected, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com