Method for manufacturing band-shaped stator core sheets and die apparatus used therefor

A band-shaped stator and a manufacturing method technology, applied in the field of mold devices, manufacturing methods and mold devices used therefor, capable of solving problems such as the separation and embedding of strip-shaped core pieces 95 which are difficult to separate from each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

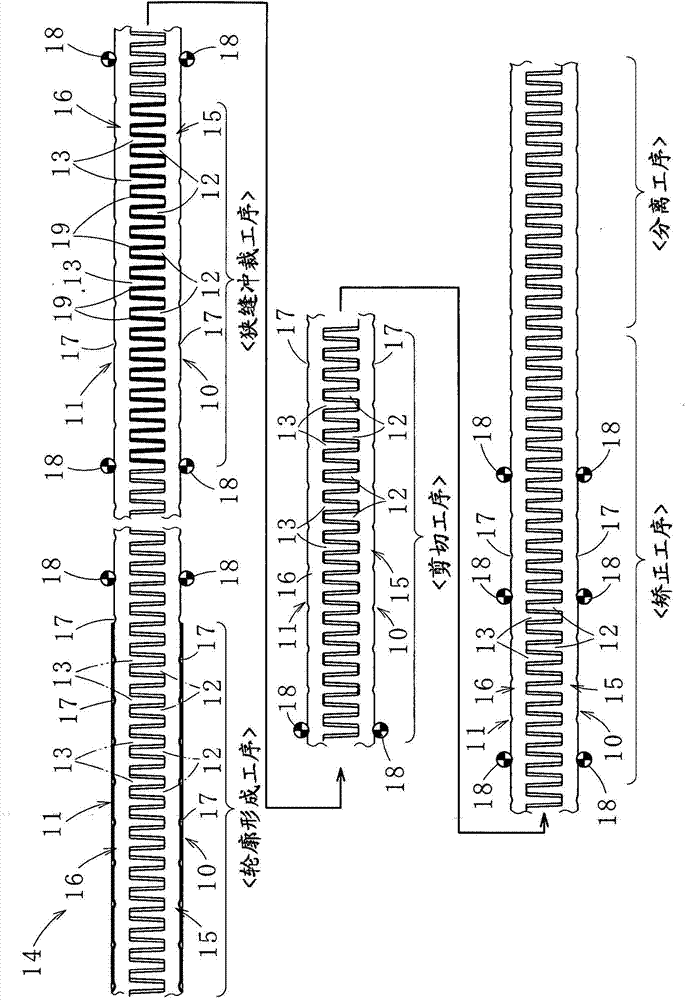

[0059] Next, referring to the attached drawings, the embodiment of the present invention will be described for understanding of the present invention.

[0060] Such as figure 1 As shown, the method for manufacturing a strip-shaped stator core sheet according to an embodiment of the present invention includes first and second strip-shaped stator core sheets (hereinafter also simply referred to as strip-shaped core sheets) 10 and 11, and the strip-shaped The magnetic pole piece parts 12 and 13 of the core pieces 10 and 11 are discharged on the magnetic strip 14 in the meshed state, and the strip-shaped core pieces 10 and 11 are separated from the magnetic strip 14 by press working. Forming process, slit punching process, shearing process, straightening process and separation process. Next, it will be described in detail.

[0061] (preparation process)

[0062] The first and second strip-shaped core pieces 10 and 11 are laid out on a magnetic strip 14 made of an electromagnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com