A workbench for a plug-in machine

A workbench and plug-in machine technology, which is applied in the direction of assembling printed circuits with electrical components, can solve the problems of large space occupied by the workbench, large safety hazards, and increase the space occupied by the plug-in machine equipment, so as to reduce the space occupied by the site and improve the Safety, obvious improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

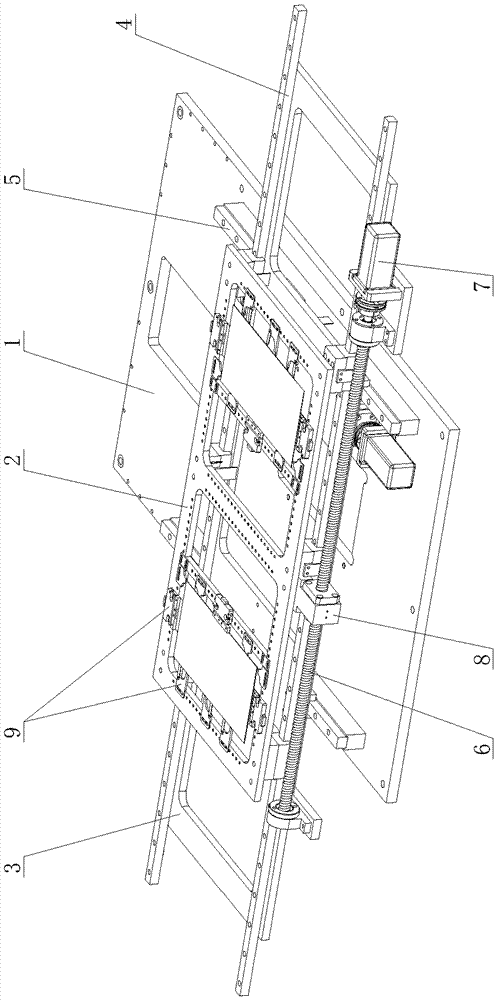

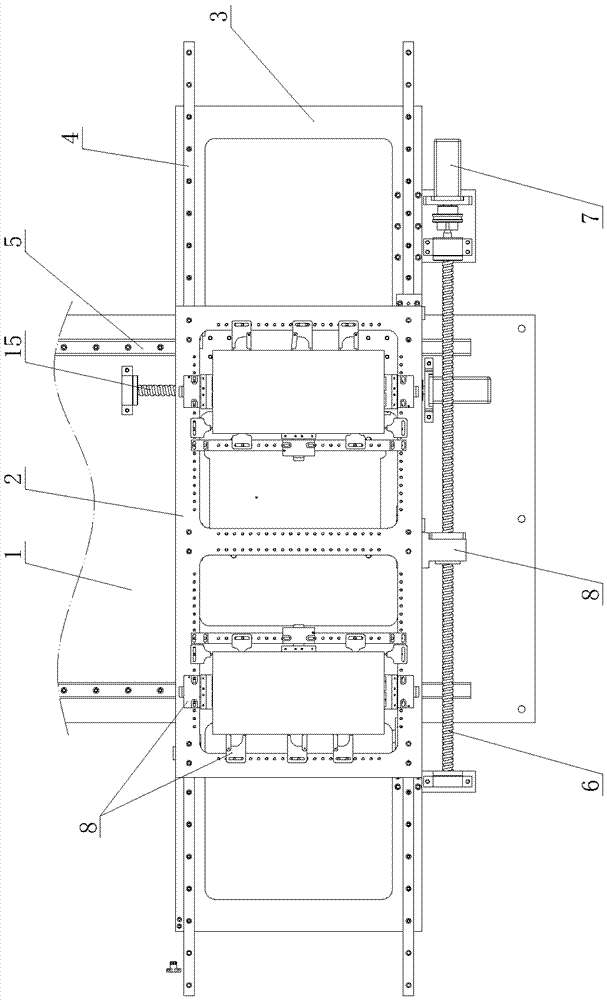

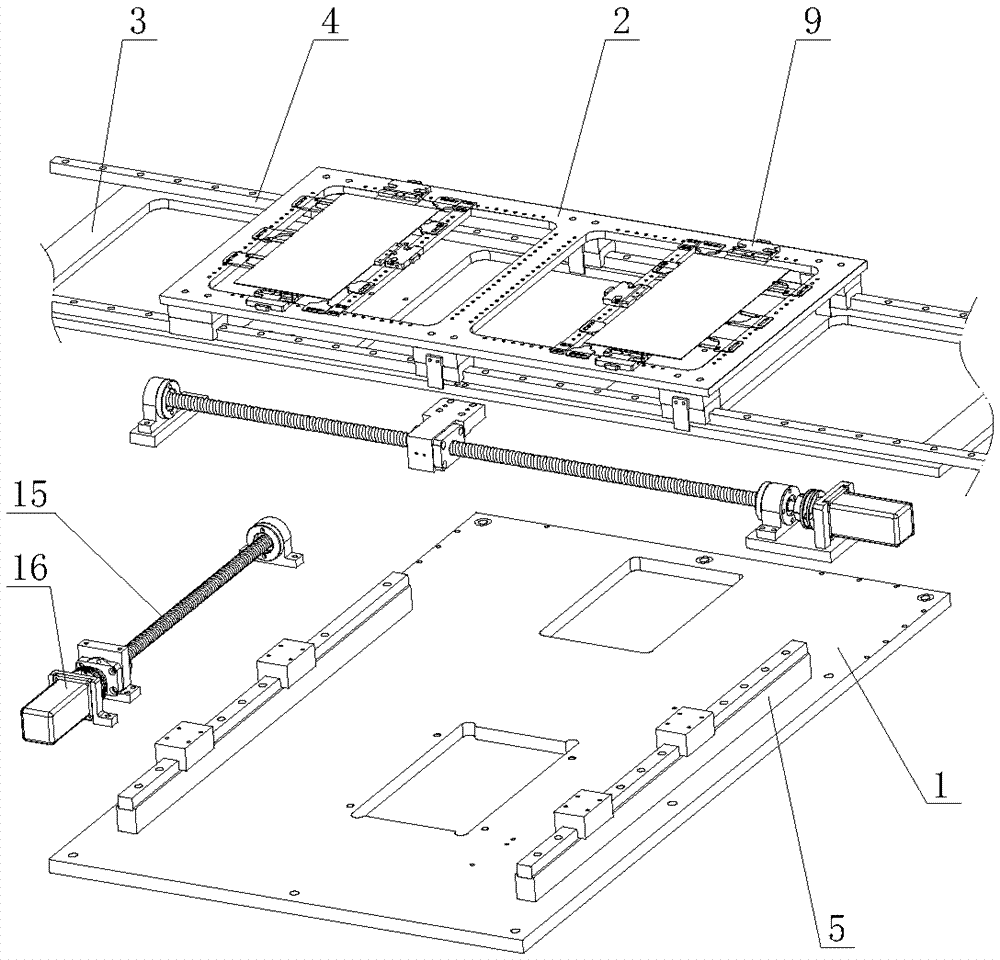

[0021] like Figure 1 to Figure 5 As shown, a workbench for a plug-in machine includes a mounting base 1, a PCB fixture 2 mounted on the mounting base 1 that can move horizontally, and a lateral movement drive mechanism for driving the lateral movement and longitudinal movement of the PCB fixture 2 respectively. A longitudinal movement drive mechanism, the PCB fixture 2 is equipped with two clamping stations, which are respectively a left clamping station and a right clamping station, and the installation base 1 is equipped with a longitudinal movement that can move forward and backward horizontally. Frame 3, the vertical movement frame 3 is equipped with a traversing slide rail 4, and the P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com