Open type sand mold casting production device

A technology of casting production and wire sand, which is applied in the field of open wire sand casting production equipment, and can solve the problems of low production efficiency, waste, and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0017] In the present invention, a PLC controller, an automatic molding machine, a molding conveying channel, a first casting conveying mechanism, a second casting conveying mechanism, a plurality of trolleys, a plurality of casings and pressing irons, an automatic casting machine, a casting mold pushing device, and a conveying The mechanism, sand scraping device and vibrating shakeout machine are existing equipment in existing sand casting, so no specific description is given for their structure.

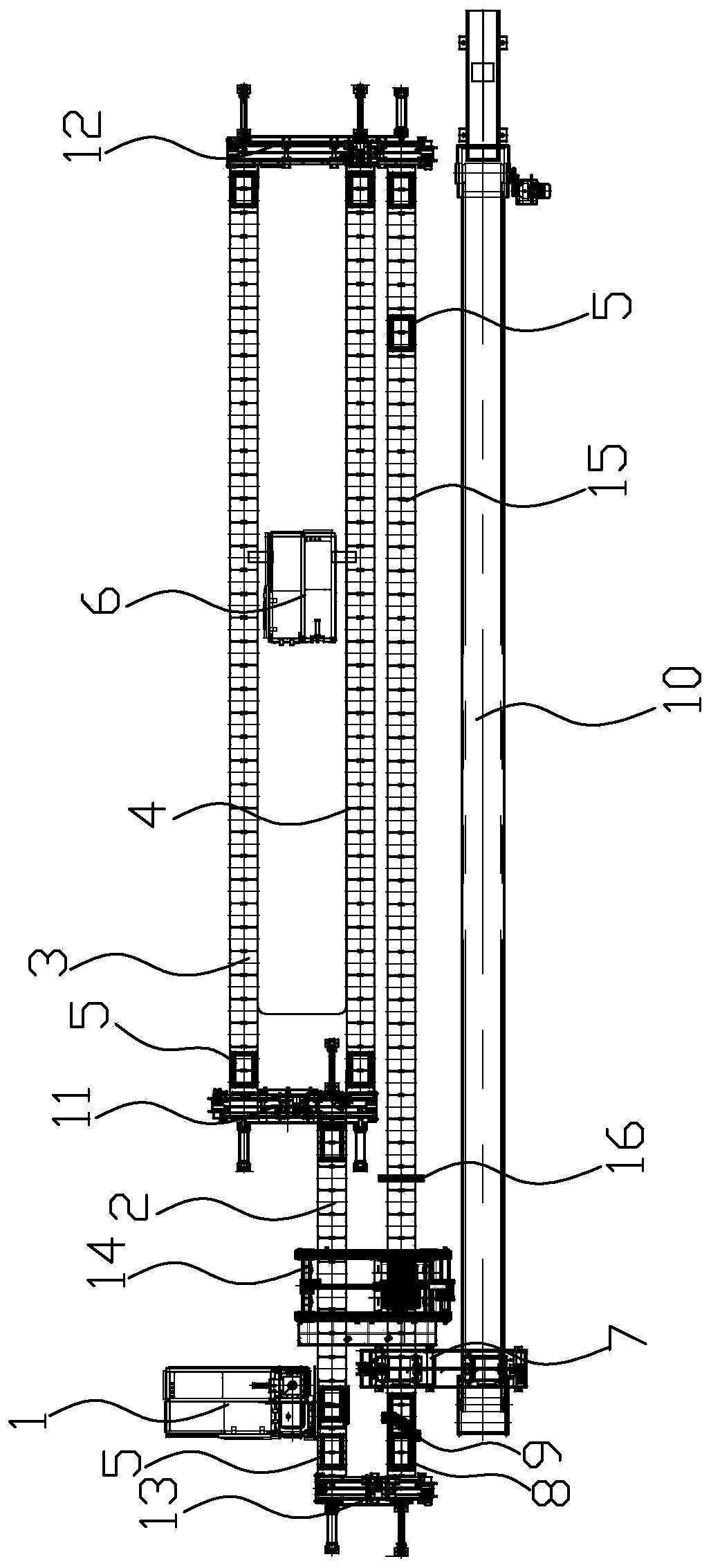

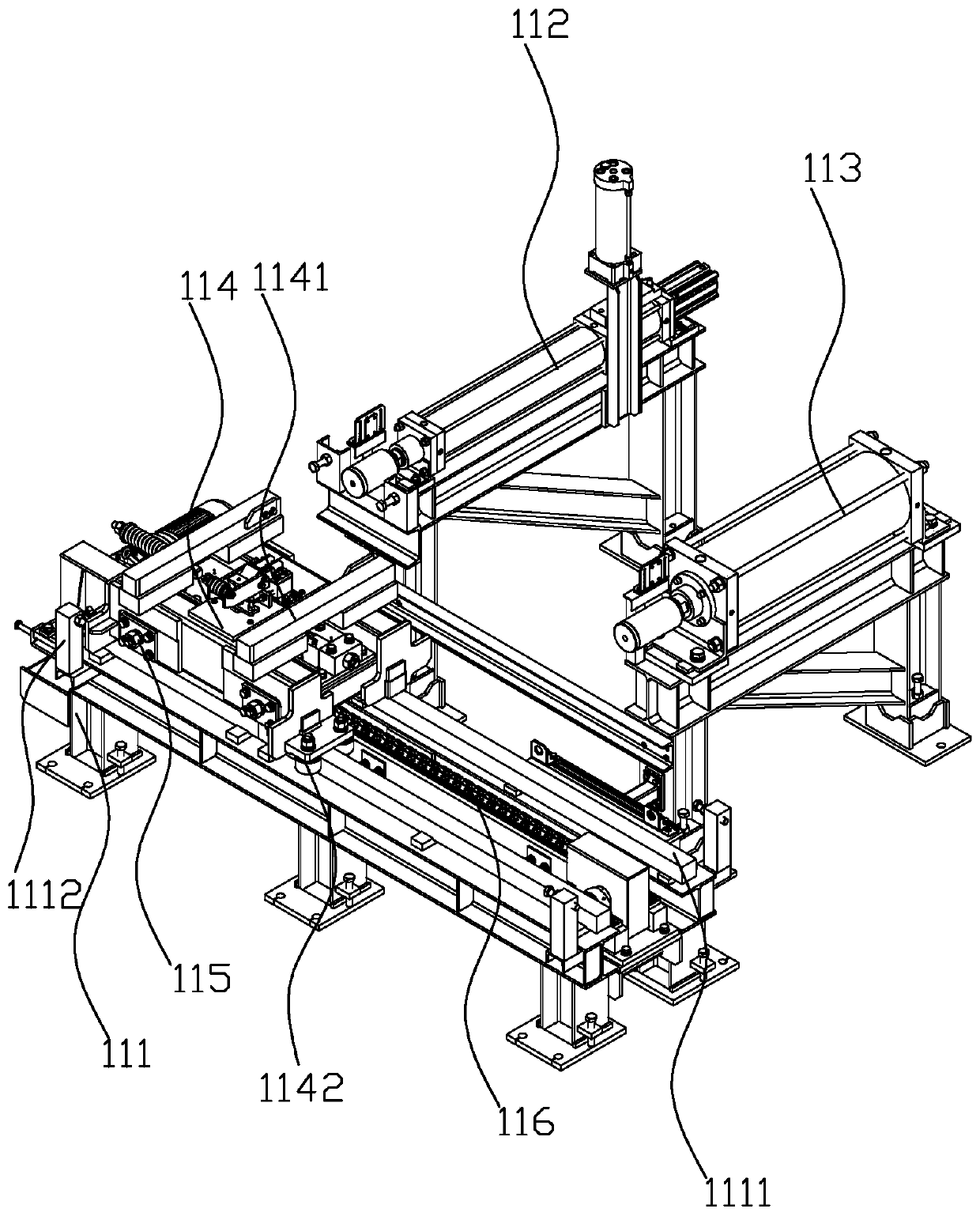

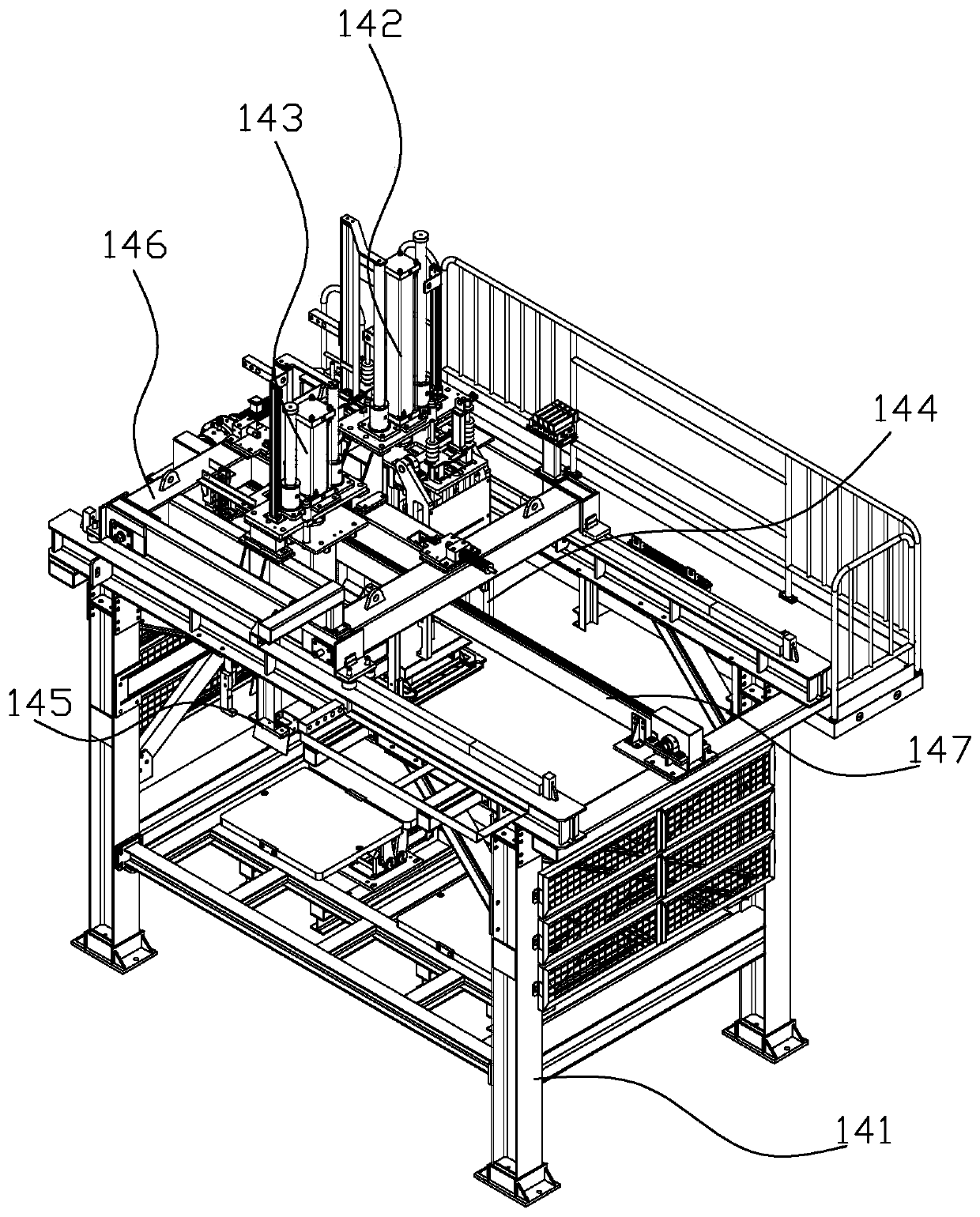

[0018] refer to figure 1, the preferred open-line sand casting production device of the present invention includes a PLC controller, an automatic molding machine 1, a molding conveyor 2, a first casting conveyor mechanism 3, a second casting conveyor mechanism 4, a plurality of trolleys 5, a plurality of A casing and weight iron, automatic casting machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com