Intelligent concave-bottom vacuum cup welding machine

A bottom heat preservation and cup welding machine technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of difficult mechanical welding, unreasonable design, and easy to produce defective products, so as to reduce the production process and facilitate operation , good welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

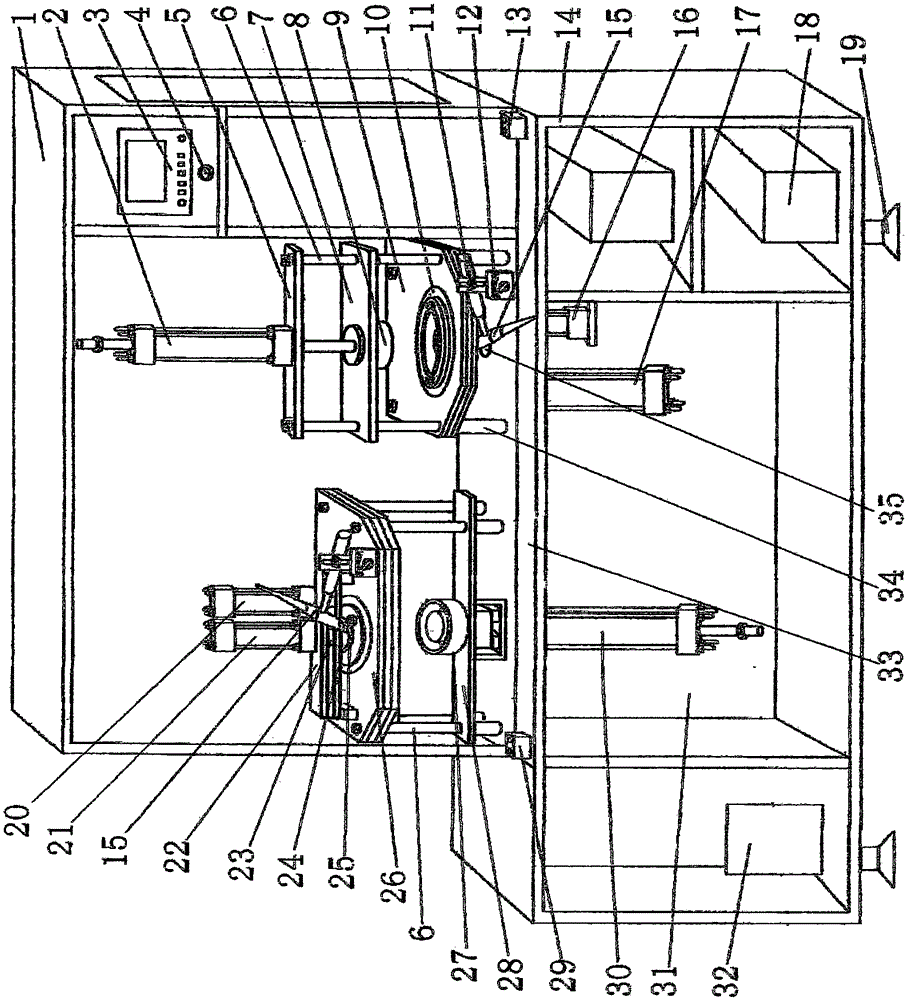

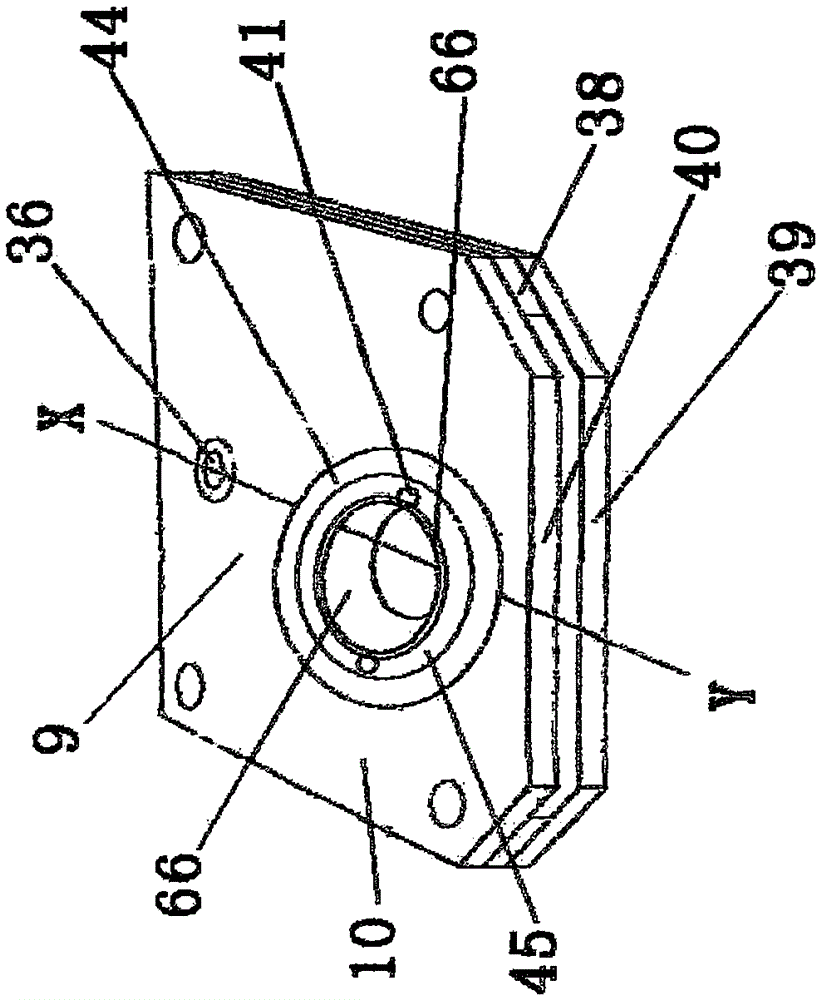

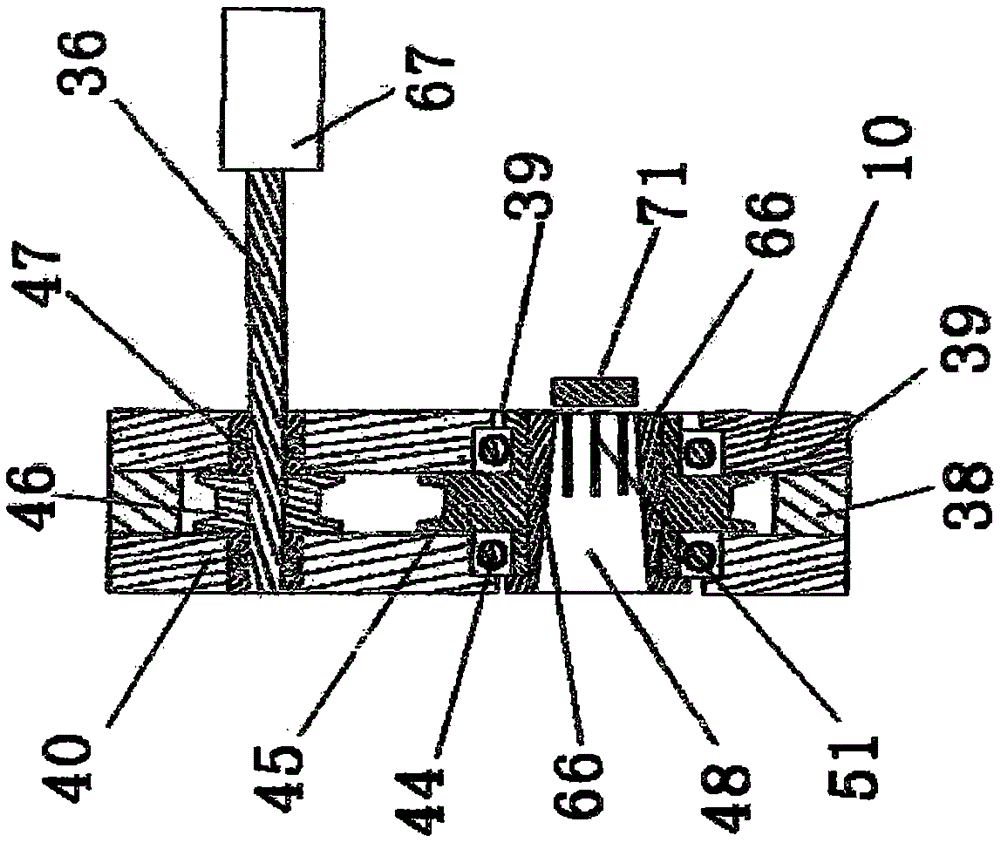

[0028] in figure 1 Among them, the frame 14 on the upper part of the platen 33 is composed of an upper box, a cup opening slide plate 7 and a flat oil cylinder 20, and the frame 14 on the lower part of the platen is composed of a lower box 31. The frame 14 is welded with iron plate 1 and machine feet 19 , The cup opening mechanism 25 and the cup bottom mechanism 10 are installed on the upper box. In the cup opening mechanism 25, the cup opening fixing plate 26 is composed of an upper splint, a lower splint and a backing plate, and is installed in the cup fixing plate There are a driven wheel and a driving wheel. The driving wheel is connected to the welding motor. The upper and lower clamping plates of the cup fixing plate 26 are equipped with large bearings. The large bearing is equipped with a driven wheel, and the cup die is installed on the driven wheel. Fix it with screws. A fixing frame 22 and a magnetic suction block 12 are installed on the cup opening fixing plate. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com