A fully automatic riveting machine

A riveting press, fully automatic technology, applied in capacitor manufacturing, electrical components, capacitors and other directions, can solve the problems of reduced post-processing work efficiency, unsuitable for industrialized large-scale production, complex assembly machine structure, etc., to avoid low post-processing efficiency. , The device structure is easy to operate, and the site takes up less space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

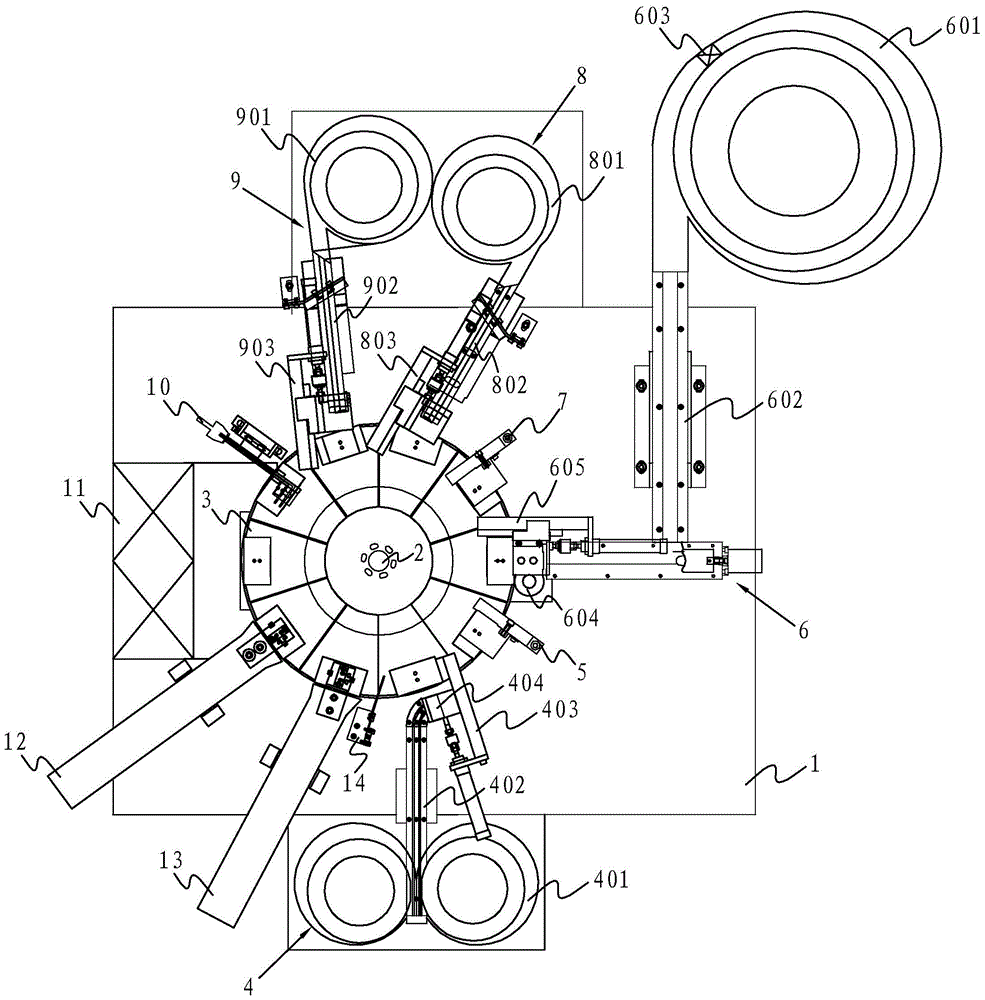

[0030] Such as figure 1 As shown, a full-automatic riveting press includes a frame, a transmission transmission mechanism arranged on the frame, and a rotary conveying device driven by the transmission transmission mechanism. The rotary conveying device includes a worktable 1, and the center of the worktable 1 is arranged There is a vertical shaft 2 coaxially connected with the transmission transmission mechanism. The outer periphery of the worktable 1 is composed of ten mold tables 3 that rotate around the vertical shaft 2. Each mold table 3 is equipped with a capacitor cover mold. There are two holes on the cover mold. A hole that fits the size of the pin rivet; the transmission speed change mechanism can be adjusted arbitrarily according to actual needs, and its transmission mode can be one or more of discs, crawlers, endless plate chains, and annular tracks.

[0031] The pin rivet upper mold device 4, the pin rivet detection device 5, the lid upper mold device 6, the lid d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com