Plug-in machine double side push type head plug-in mechanism

A plug-in machine and head technology, which is applied in the field of plug-in machine double-side push-type head plug-in mechanism, can solve the problems of increasing the production cost of manufacturers, increasing the amount of waste products, and plugging failures, so as to improve the accuracy of plug-in, Improved processing quality and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

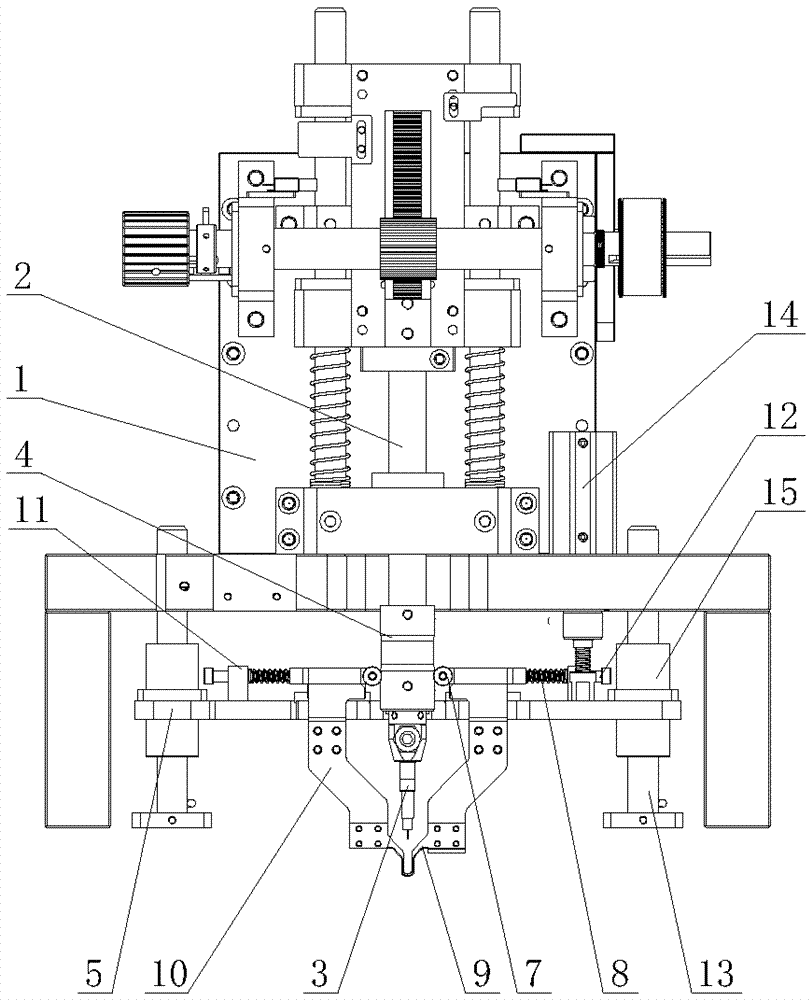

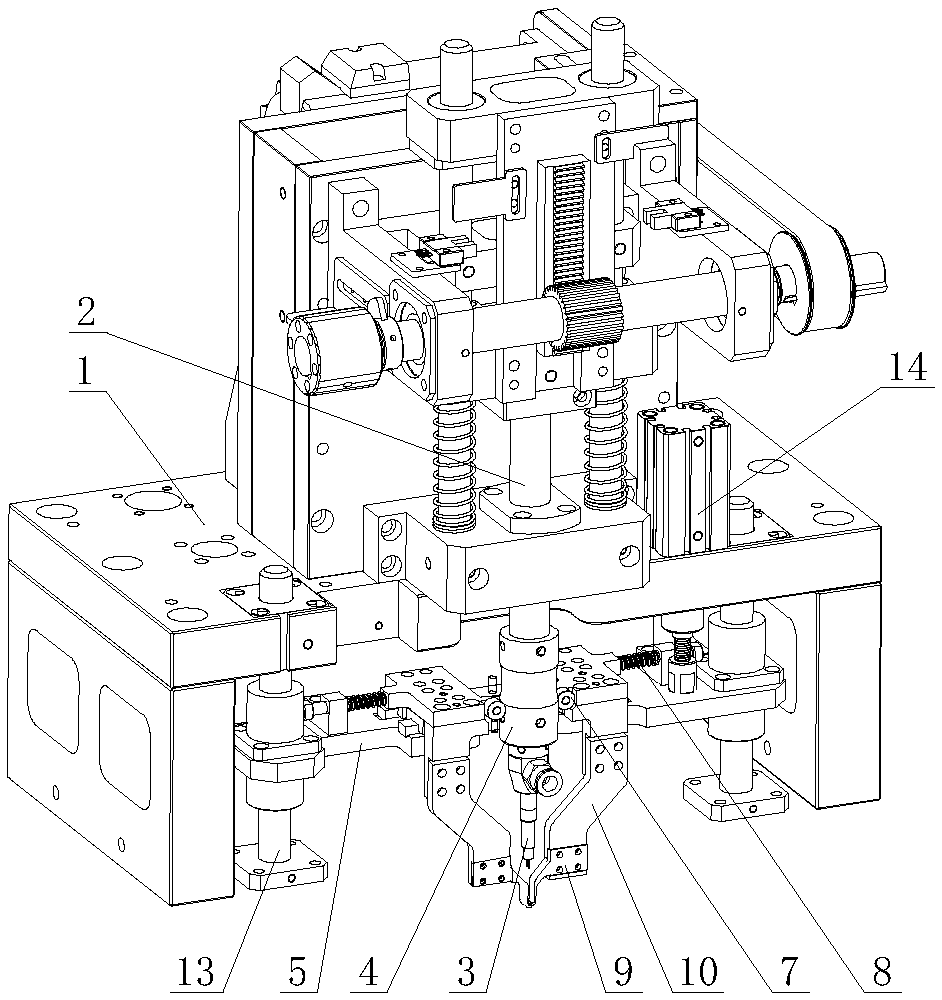

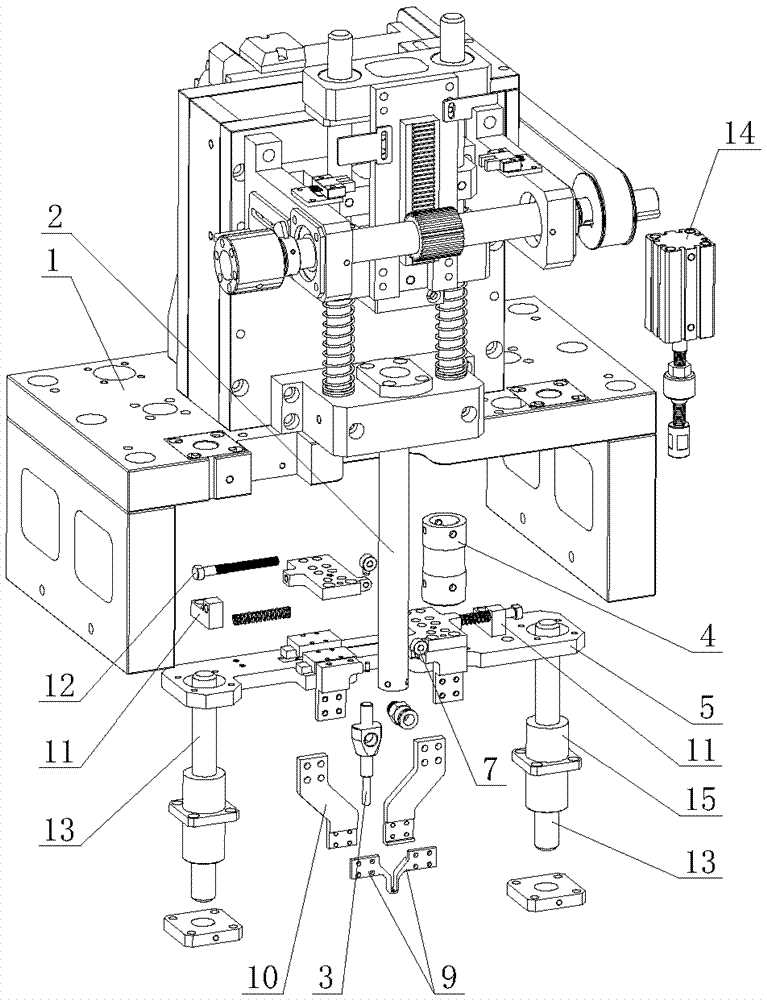

[0016] Such as Figure 1 to Figure 3 As shown, a plug-in machine double-side push-type head plug-in mechanism includes a head base 1 and a drive shaft 2 mounted on the head base 1 that can move up and down. The lower end of the drive shaft 2 is equipped with a suction rod 3. The drive shaft 2 is set with a linkage sleeve 4, the side wall of the linkage sleeve 4 is provided with a side push curved surface, and a liftable fixing plate 5 is installed under the head base 1, and the fixing plate 5 is installed A guide device for the opening and closing of the material foot is provided under the driving action of the side pushing curved surface.

[0017] During the insertion process of the plug-i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com