Construction method of steel pipe pile steel trestle bridge

A construction method and technology of steel pipe piles, applied in bridges, sheet pile walls, bridge materials, etc., can solve the loss of personal safety of construction workers, poor stability of steel trestle construction platforms, and relatively large displacement of pile tops, etc. problems, to achieve the effect of improving construction quality, firm bottom and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

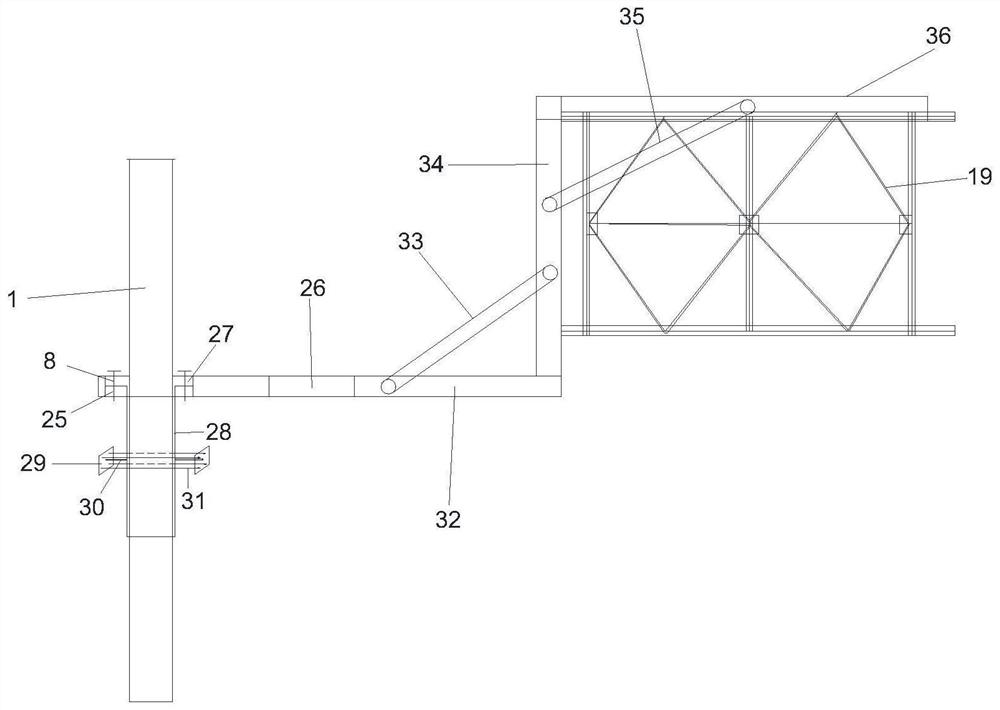

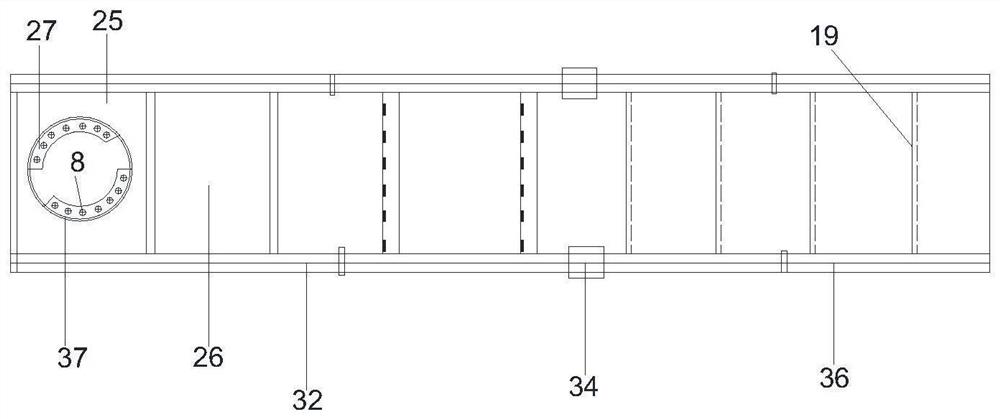

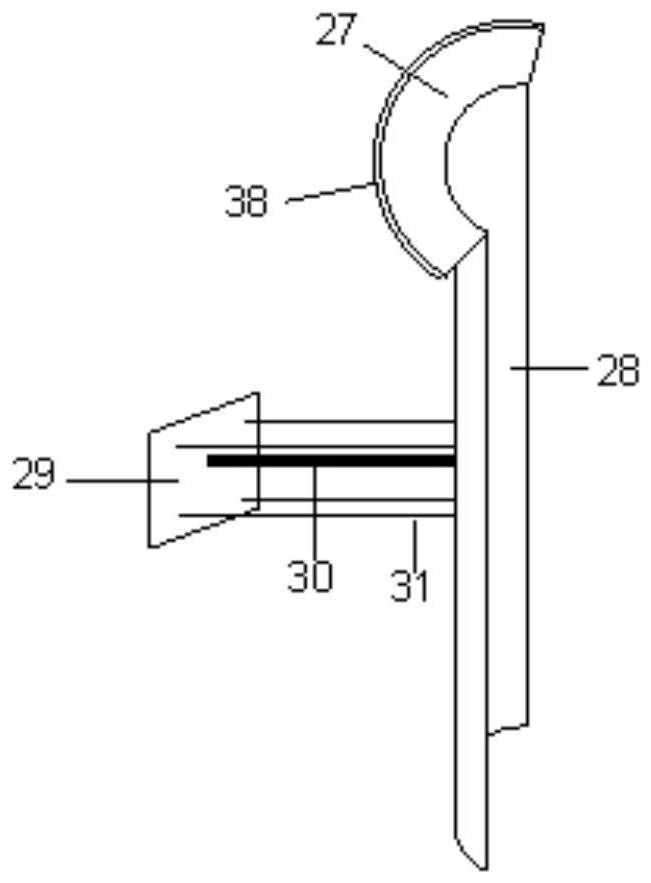

[0043] This embodiment provides a positioning device for an assembled cantilever guide frame of an inclined steel pipe pile, which is installed on the Bailey main beam 19 that has been constructed, including: a lower horizontal frame 32; multiple limit positions are set on the lower horizontal frame 32 Holes 26, holed steel plates 25 are set on the limit holes 26, vertical arc plates 28 with movable bottom end plates 27 are arranged symmetrically on the steel plates with holes 25, ear plates 29 are set on the vertical arc plates 28; bottom end plates 27 Arc-shaped sliding grooves 38 are arranged around, and the bottom end plate 27 can slide along the circular sliding tracks 37 around the steel plate 25 with holes. The bottom end plate 27 and the vertical arc plate 28 are welded together. The positions of the limiting holes 26 are fixed in front, back, left and right. The ear plate 29 is circumferentially arranged on the outer wall of the vertical arc plate 28 . The lug plate...

Embodiment 2

[0051] This embodiment provides a steel trestle with steel pipe piles, comprising: steel pipe piles 1; a cutting groove 9 is cut on the top of the steel pipe pile 1, and a pillow beam is placed in the cutting groove 9, and the pillow beam includes a lower wing plate 39 of the pillow beam And pillow beam upper wing plate 11, horizontal supporting steel plate 6 is set at pillow beam lower wing plate 39, L-shaped reinforcement plate is set at pillow beam upper wing plate 11, Bailey main beam 19 is placed on pillow beam upper wing plate 11; Bailey main beam 19 is installed in turn There are I-steel distribution main beam 20, I-steel distribution sub-beam 21, patterned steel panel 22, I-steel distribution sub-beam 21 is provided with protective railing 24; the outer wall of steel pipe pile 1 is provided with multi-stage ring ear plates . Steel pipe flat connections 16 and steel pipe diagonal braces 17 are installed between each steel pipe pile 1 after the pile sinking is fixed. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com