PCBA positioning tool and positioning method of PCBA compression joint technology

A tool and process technology, applied in the field of PCBA positioning tools and positioning, can solve the problems of low centering efficiency, difficult centering, and inability to extend the pins, so as to improve the centering accuracy, reduce the centering difficulty, and shorten the centering. medium time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

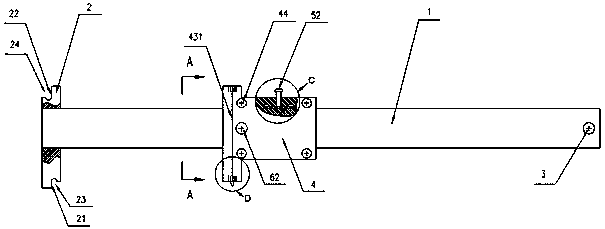

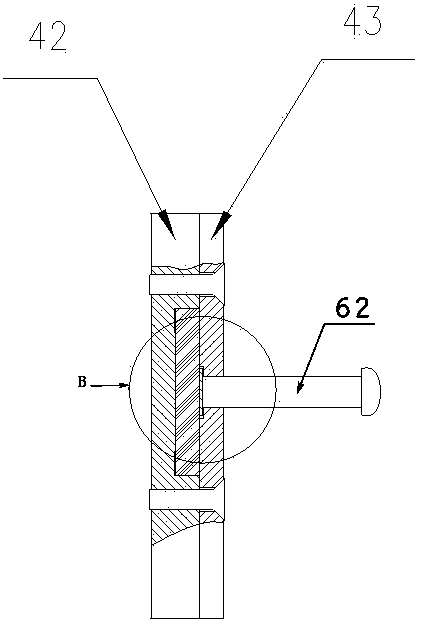

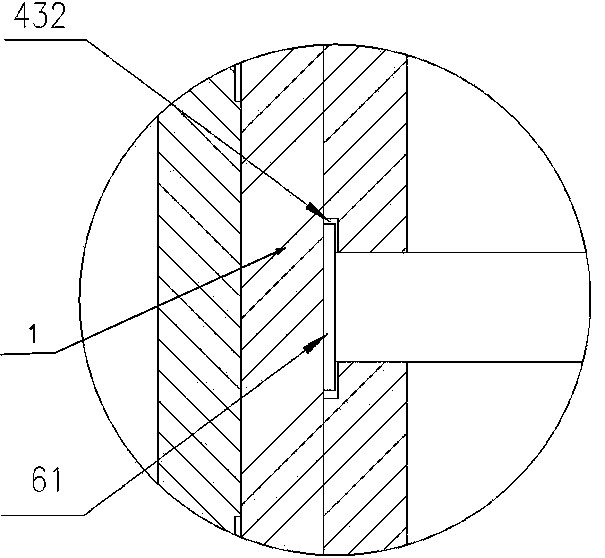

[0038] Such as Figures 1 to 2 As shown, an embodiment of the positioning tool of the present invention includes a main ruler 1, a base block 2 and a vernier 4, wherein the base block 2 is perpendicular to the main ruler 1, and is fixed on the left end of the main ruler 1, and there is a The lower right notch 23 facing right, the left elevation of the lower right notch 23 is the PCB side positioning surface 21, the upper left corner of the base block 2 has a left upper notch 24 facing left, and the right elevation of the left upper notch 24 is crimping The equipment fixture positioning surface 22, the crimping equipment fixture positioning surface 22 and the PCB side positioning surface 21 are located on the same plane, the cursor 4 includes a guide box 42, a front cover 43 and a positioning pin 41, the guide box 42 and the front cover 43 Fixed by fastening screws 44, a hollow through hole is formed between the guide box 42 and the front cover 43, the main scale 1 passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com