Solar cell and contact structure thereof, cell assembly and photovoltaic system

A solar cell and contact structure technology, applied in the field of solar cells, can solve the problems of complex doping polysilicon process, high process difficulty, expensive equipment, etc., and achieve the effect of avoiding high temperature diffusion process, good deposition effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

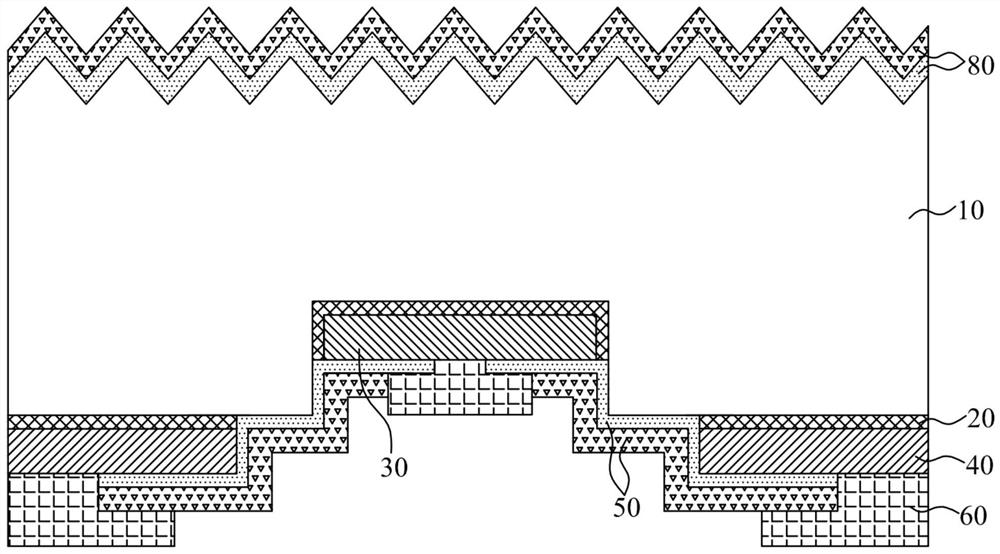

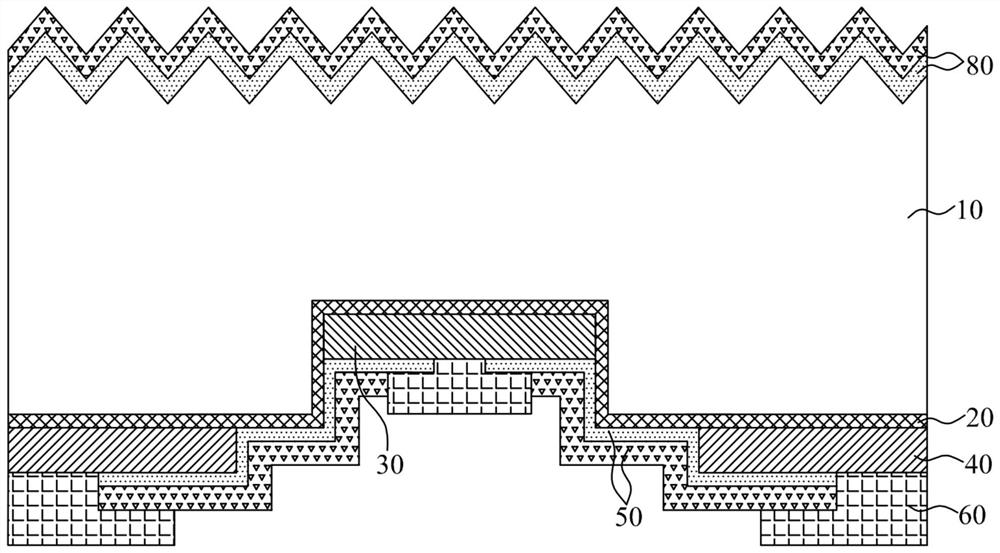

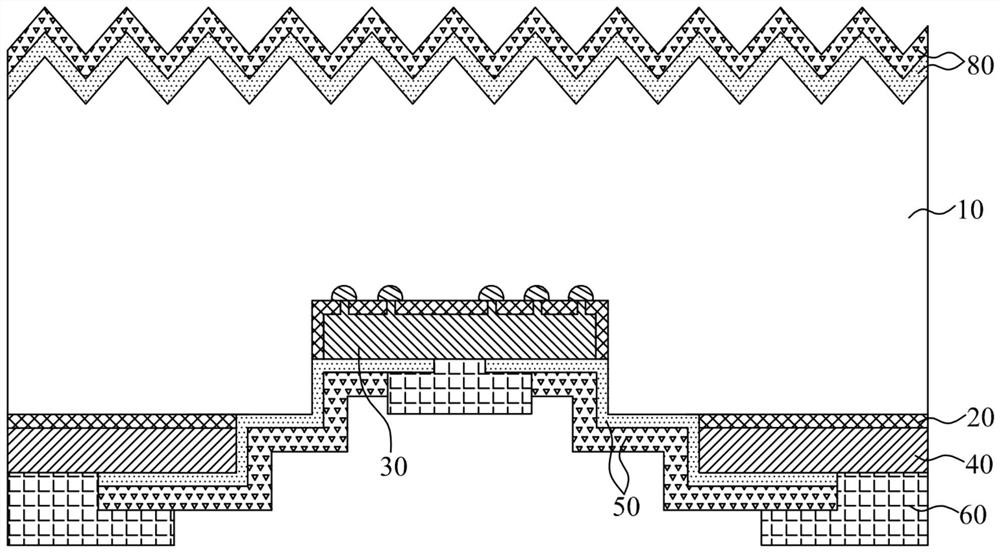

[0075] The embodiment of the present invention provides a contact structure of a solar cell. For the convenience of description, only the parts related to the embodiment of the present invention are shown. Refer to Figure 1 to Figure 11 As shown, the contact structure of the solar cell provided by the embodiment of the present invention includes:

[0076] Grooves arranged at intervals on the back side of the silicon substrate 10;

[0077] A first dielectric layer 20 disposed on the back side of the silicon substrate 10;

[0078] a first selective contact region 30 disposed on the first dielectric layer 20 and disposed in the groove;

[0079] a second selective contact region 40 disposed on the first dielectric layer 20 and disposed outside the groove;

[0080] a second dielectric layer 50 disposed between the first selective contact region 30 and the second selective contact region 40, the second dielectric layer 50 being at least one layer; and

[0081] a conductive layer ...

example 2

[0093] Therefore, in the example in which the hole selective contact region and the electron selective contact region are both non-silicon contact layers, it also includes Example 1: the first selective contact region 30 disposed in the groove is a non-silicon contact layer. The hole selective contact region of the layer, the second selective contact region 40 arranged outside the groove is an electron selective contact region using a non-silicon contact layer; and Example 2: the first selective contact region arranged in the groove The region 30 is an electron selective contact region using a non-silicon contact layer, and the second selective contact region 40 disposed outside the groove is a hole selective contact region using a non-silicon contact layer.

example 3 no. 1 30P, no. 2 40; and example 4

[0094] A specific example in which one of the above-mentioned ones is a non-silicon contact layer and the other is a silicon-based contact layer can be that the hole selective contact region is a non-silicon contact layer, and at this time, the electron selective contact region is a silicon-based contact layer. layer, for example specifically N-type doped polysilicon; or the hole selective contact region is a silicon-based contact layer, for example specifically P-type doped polysilicon, and in this case the electron selective contact region is a non-silicon contact layer. Therefore, it includes Example 1: the first selective contact region 30 arranged in the groove is a hole selective contact region using a non-silicon contact layer, and the second selective contact region 40 arranged outside the groove is a hole selective contact region using an N-type contact layer. Electron selective contact region doped with polysilicon; Example 2: The first selective contact region 30 arr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Work function | aaaaa | aaaaa |

| Work function | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com