Method for manufacturing reserved window leaded by shadow mask in production of dielectic layer of plasma display

The technology of a plasma display and a manufacturing method is applied in the field of manufacturing a shadow mask leading out a reserved window in the manufacturing of a dielectric layer of the plasma display, which can solve problems such as inconvenience of leading voltage and potential, reduce noise and difficult alignment problems, improve yield, Simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

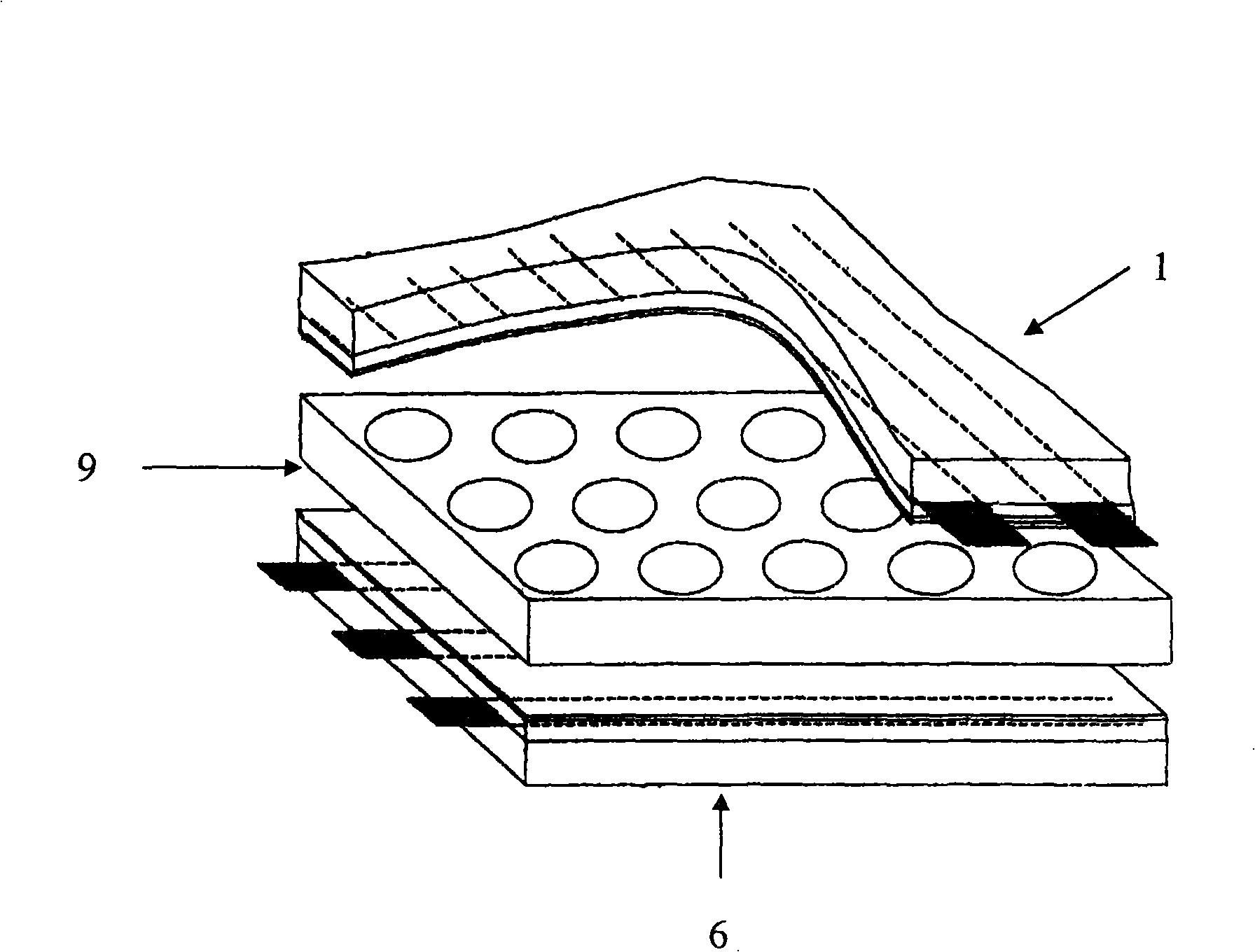

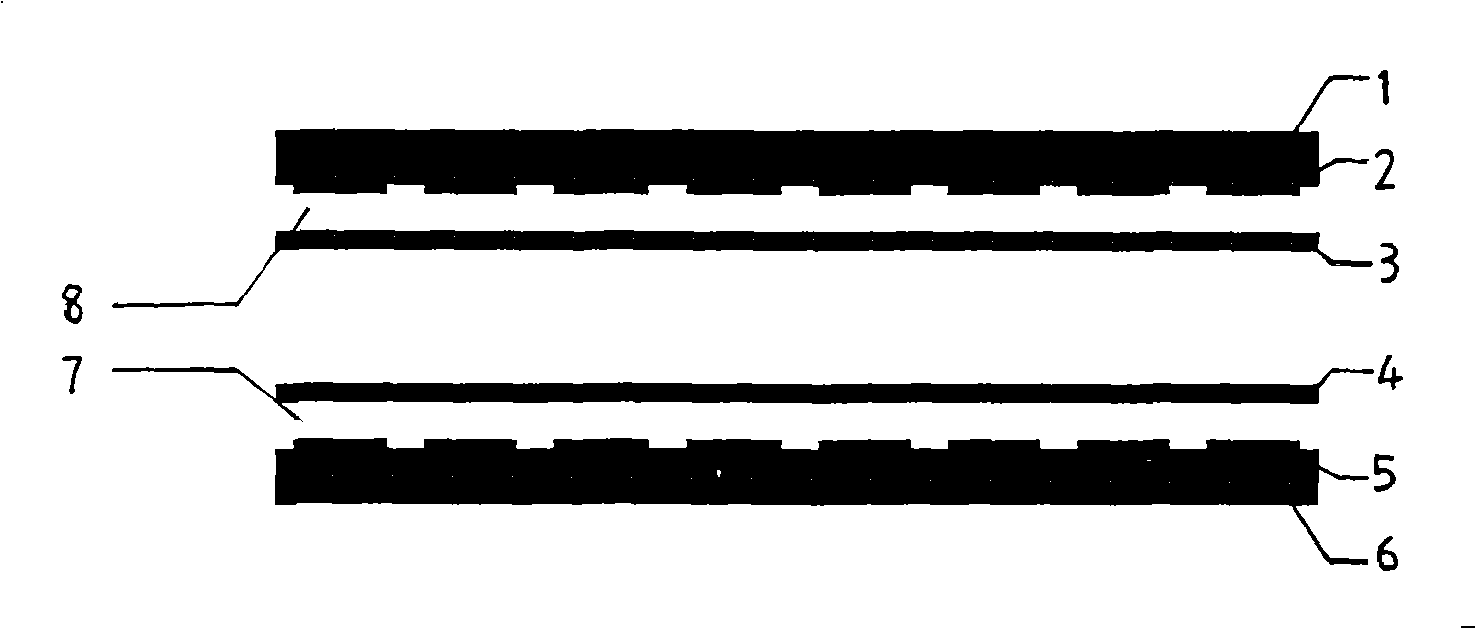

[0023] The present invention will be further described below in conjunction with the drawings and embodiments.

[0024] A method for manufacturing a shadow mask leading out a reserved window in the manufacturing of the dielectric layer of a plasma display, which includes the following steps:

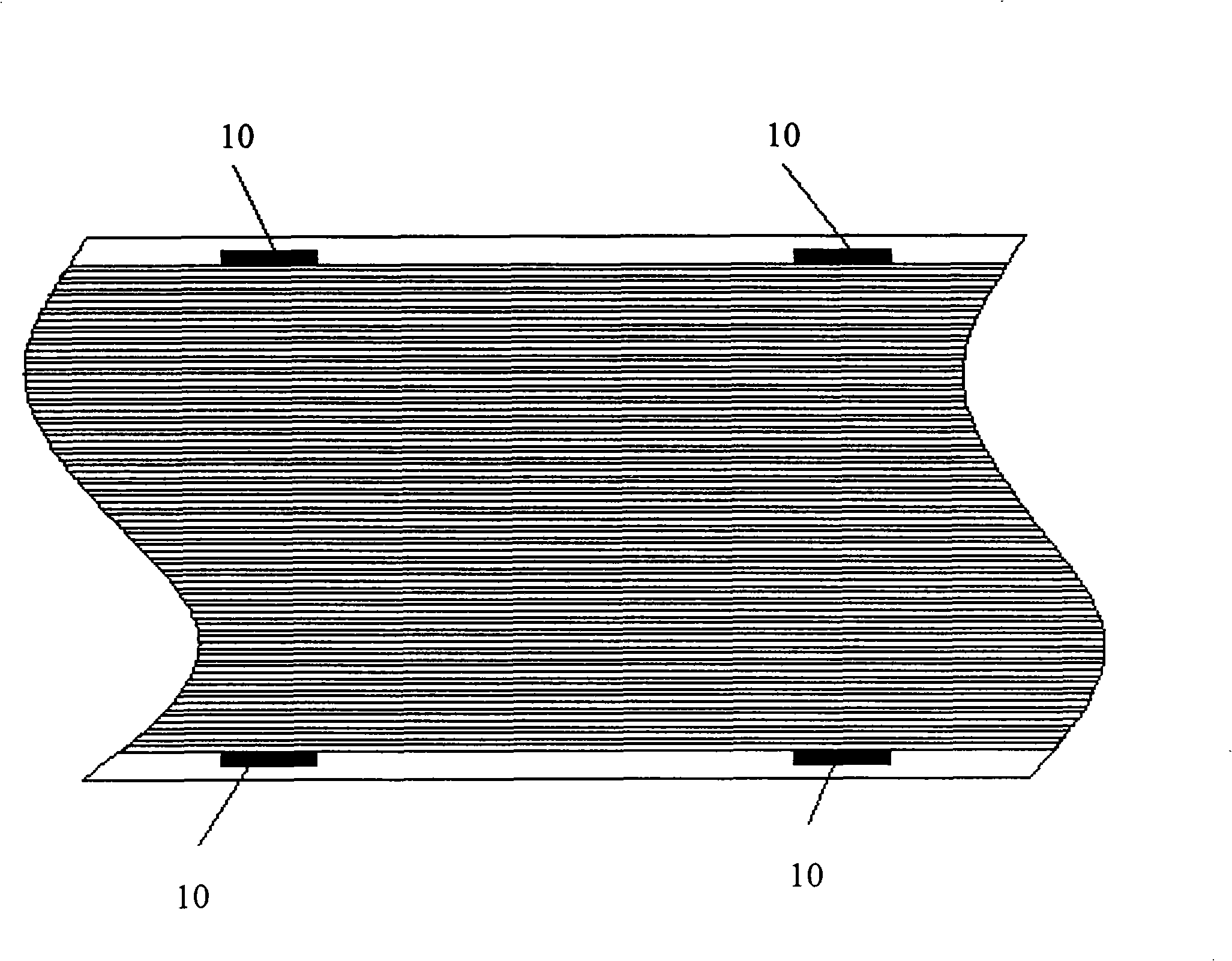

[0025] (a) A spacer 11 is attached to the electrode lead-out area 10 of the substrate with electrodes, and the thickness of the spacer 11 is less than 100um;

[0026] (b) Put the substrate with the separator 11 in the electrode lead-out area 10 into a preheating furnace for preheating, and the preheating temperature is 80℃-170℃;

[0027] (c). Make a dielectric layer on the substrate with the spacer 11 attached. After the medium is attached, a clear mark is formed on the boundary between the substrate surface and the spacer 11, and then a blade is used to scratch along the edge of the spacer 11 Open, peel the separator 11 and the dielectric layer on the electrode lead-out area 10 of the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com