Novel regulated condensed milk and preparation method thereof

A new technology for preparing condensed milk, applied in dairy products, milk preparations, applications, etc., can solve problems such as tooth decay, consumption, and large energy, and achieve the effect of reducing energy consumption, ensuring product quality, and saving electricity

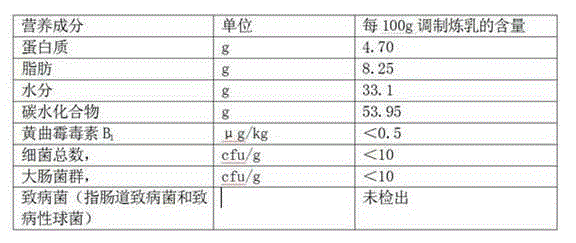

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment, the present invention will be further described, but protection scope of the present invention is not limited thereto:

[0020] The preparation steps of the present invention modulation condensed milk are as follows:

[0021] (1) Weighing of ingredients: 21.5kg of whole milk powder, 32.5kg of hot boiled water, 8kg of crystalline fructose, 35kg of maltodextrin, 3kg of cream, and 285g of micronized lactose.

[0022] (2) Preparation of lactose micropowder: Take an appropriate amount of lactose raw material (generally 1.1 to 1.2 times the amount required by the formula), use an ultrafine pulverizer to adjust to a gear of 5 microns for pulverization, and pulverize the particles to pass through a 200-mesh sieve for screening Filter, sterilize in an oven at 96°C for 8 minutes, weigh 285g of lactose micropowder, and set aside;

[0023] (3) Vacuum mixing: except lactose micropowder, put all the raw materials and boiled water into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com