Adjustable spray nozzle

A nozzle and nozzle cavity technology, applied in the direction of spraying device, spraying device, etc., can solve the problem that adjustable nozzle is not suitable for spraying device with larger spraying diameter, and achieve stable and reliable cooperation, easy installation and disassembly, and force balance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

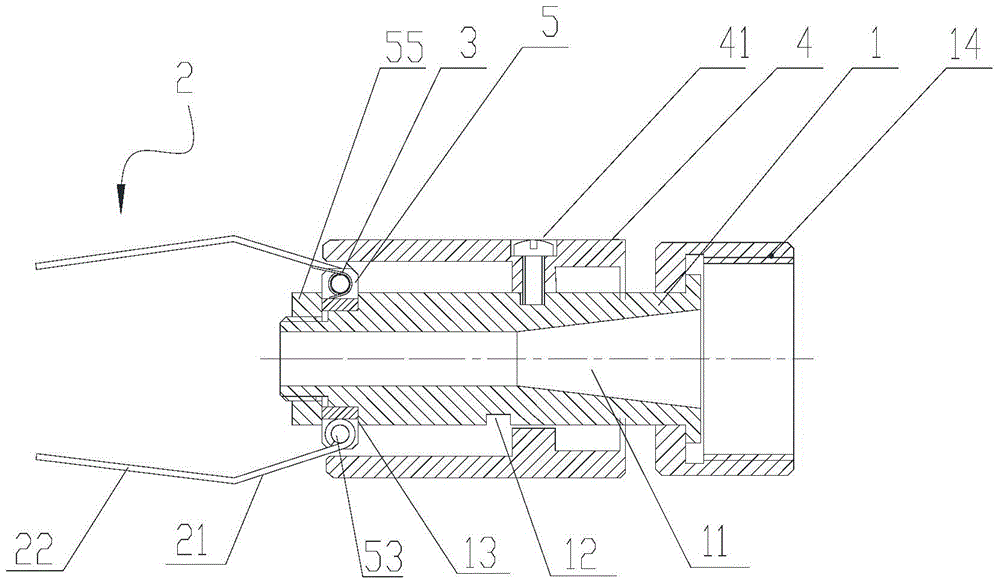

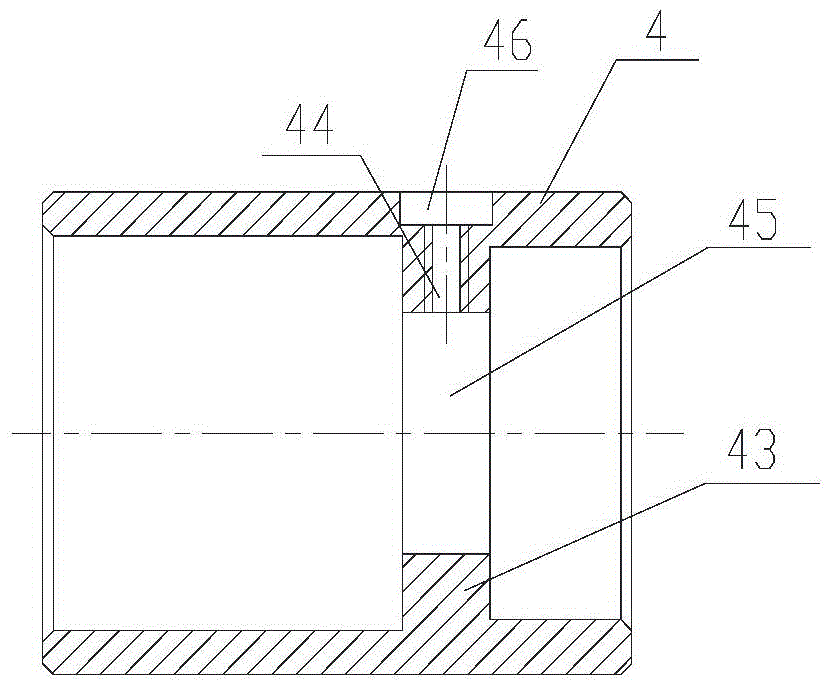

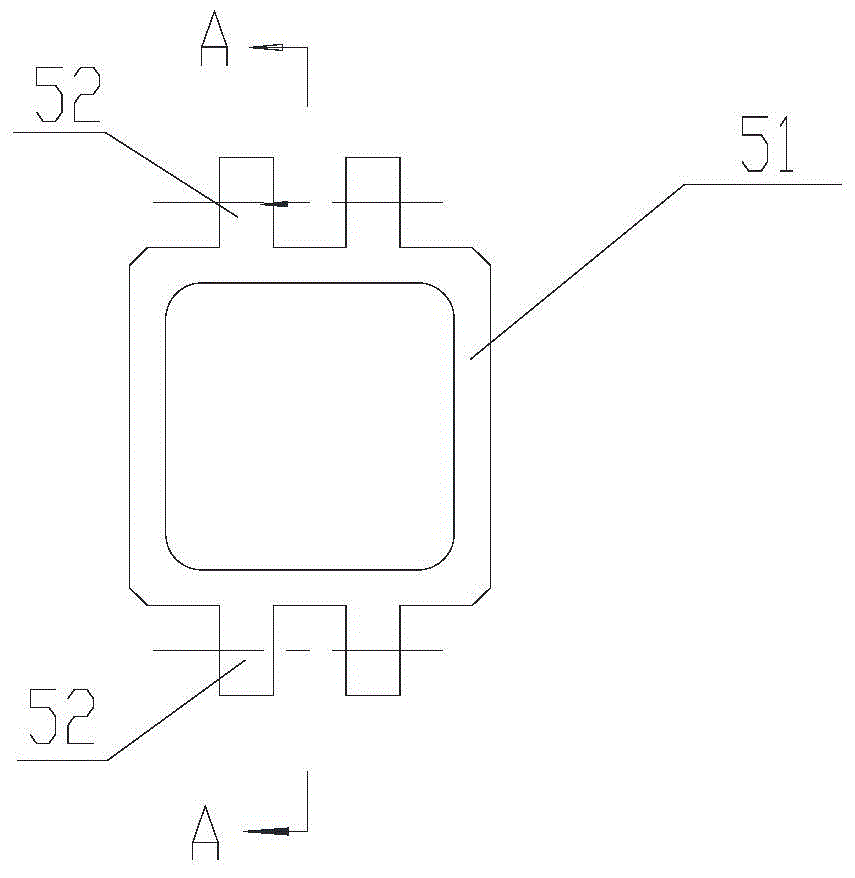

[0031] figure 1 It is an adjustable nozzle of the present invention, comprising: a nozzle body 1 , at least two baffles 2 , an elastic member 3 and an adjustment member 4 . Wherein, the nozzle body 1 has a nozzle chamber 11 that allows fluid to pass through and spray forward.

[0032] The flap 2 is hinged to the front end of the nozzle body 1 through a hinge shaft 53. In this embodiment, the rearmost end of the flap 2 is hinged to the nozzle body 1 through a hinge shaft 53, and the flap 2 can be directly hinged to the nozzle body 1, it can also be hinged on the parts fixed with the nozzle body 1. The preferred scheme will be introduced later. Each of the baffles 2 includes a first portion 21 extending outward and forward from its hinge with the nozzle body 1 , and a second portion 22 extending inward and forward from the front end of the first portion 21 . The baffle 2 can rotate around the hinge shaft 53 away from the axis of the nozzle body 1, that is, outward, and the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com