A scrap collection device used in a log processing line

A collection device and assembly line technology, applied in the field of wood processing, can solve the problems of increasing the burden on workers and confusion on the work site, and achieve the effect of maintaining the site environment and improving the collection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

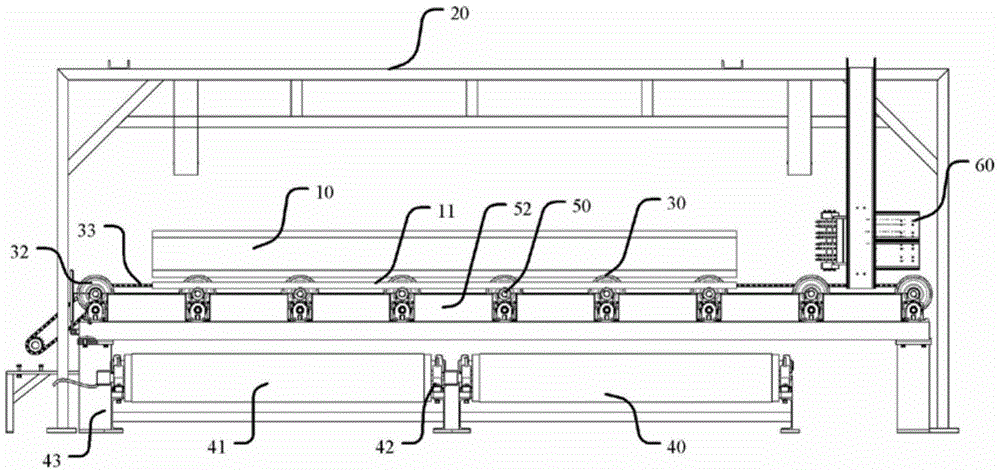

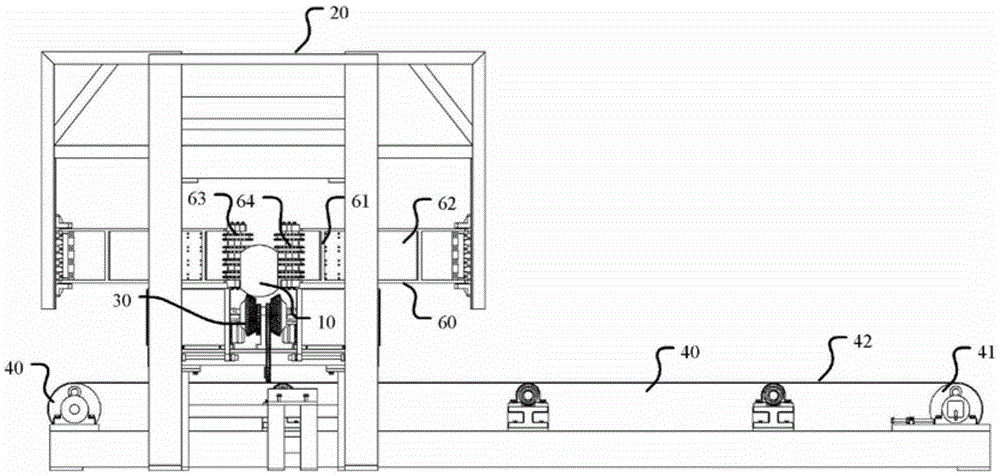

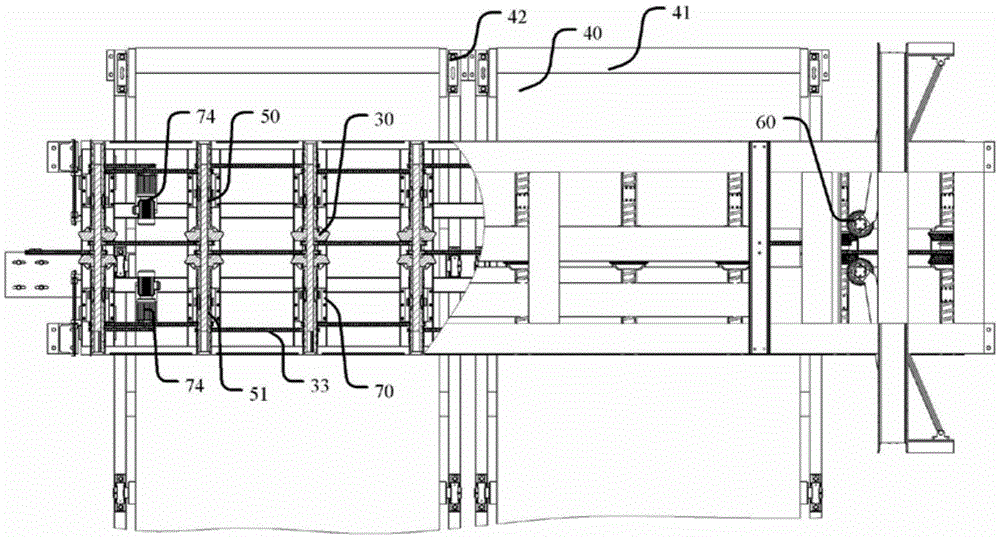

[0026] Such as figure 1 , 2 , 3, and 4, the scrap collection device of the present invention includes a mounting frame 20 and a first conveying device 30 and a second conveying device 40 installed on the mounting frame 20 . This first transmission device 30 comprises a plurality of groups of transmission wheels 31 that are installed in pairs, and each group of transmission wheels 31 is installed on the installation frame 20 with the central axis of the installation frame 20 as a symmetrical point and at intervals, and each transmission wheel 31 is formed by the first The motor 32 drives the rotation through the chain 33, thereby driving the log 10 placed on it to advance. The second conveying device 40 is installed below the conveying wheel of the first conveying device 30 at intervals and the conveying direction is perpendicular to the conveying direction of the first conveying device 30, which includes two conveying shafts 42 driven by a second motor 43 and a sleeve Convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com