Mold cart device for manufacturing cement bricks

A mold car and cement brick technology, applied in the direction of manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of uneven structure of cement bricks, insufficient firmness of finished products, and uneven distribution of materials, so as to save manpower and material resources , Small sliding resistance, smooth moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

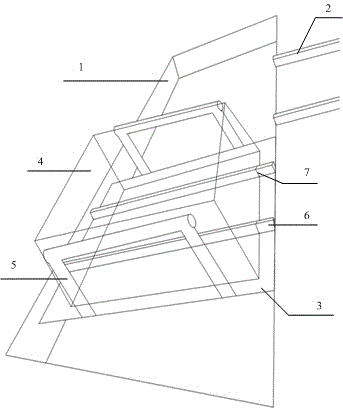

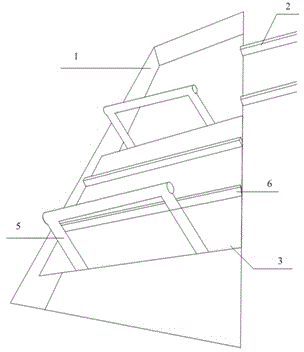

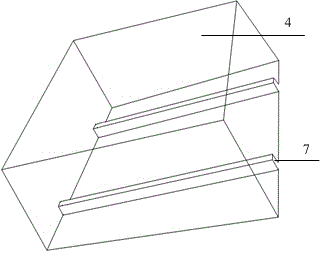

[0012] As shown in the accompanying drawings: a mold vehicle device for making cement bricks, which is characterized by: comprising a track 1, a track 2, a trolley 3 and a mold box 4; the track 2 is set outside one end of the track 1. The trolley 2 is located in the track 1, and its width is equivalent to that of the track 1. Rectangular railings 5 are welded on both sides, and a track 6 is made above the bottom; the track 6 is exactly the same in width and height as the track 2. The size of the mold box 4 is slightly smaller than that of the trolley, and two grooves 7 are arranged on the bottom thereof; the periphery of the groove 7 is slightly larger than the periphery of the track 6 .

[0013] The working principle and usage method of the present invention are: before use, place the empty mold box 4 on the track 2, push the trolley 3 to align with the track 2, and then push the mold box 4 to move it onto the trolley 3; After the mold box 4 is filled with cement material, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com