Self-driving Rope Traction Monorail Crane System

A monorail crane and rope traction technology, applied in the direction of tram tracks, cable railways, motor vehicles, etc., can solve the problems of hidden danger of falling off the track, restricted promotion and application, etc., and achieve the effect of convenient and fast moving, convenient fixing and reliable braking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

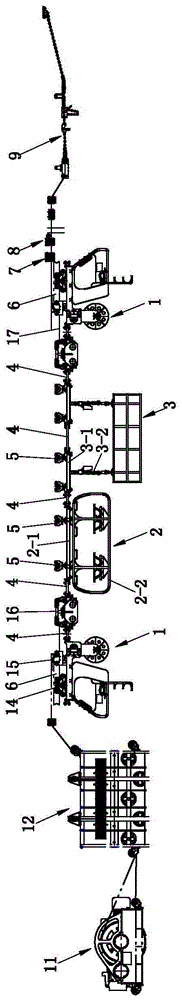

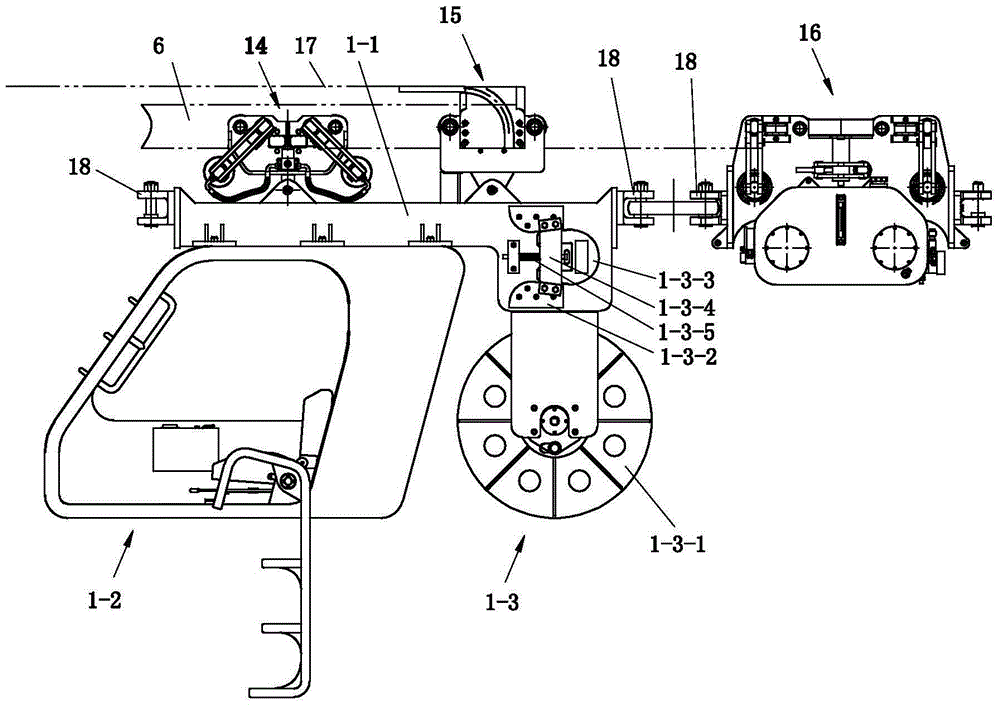

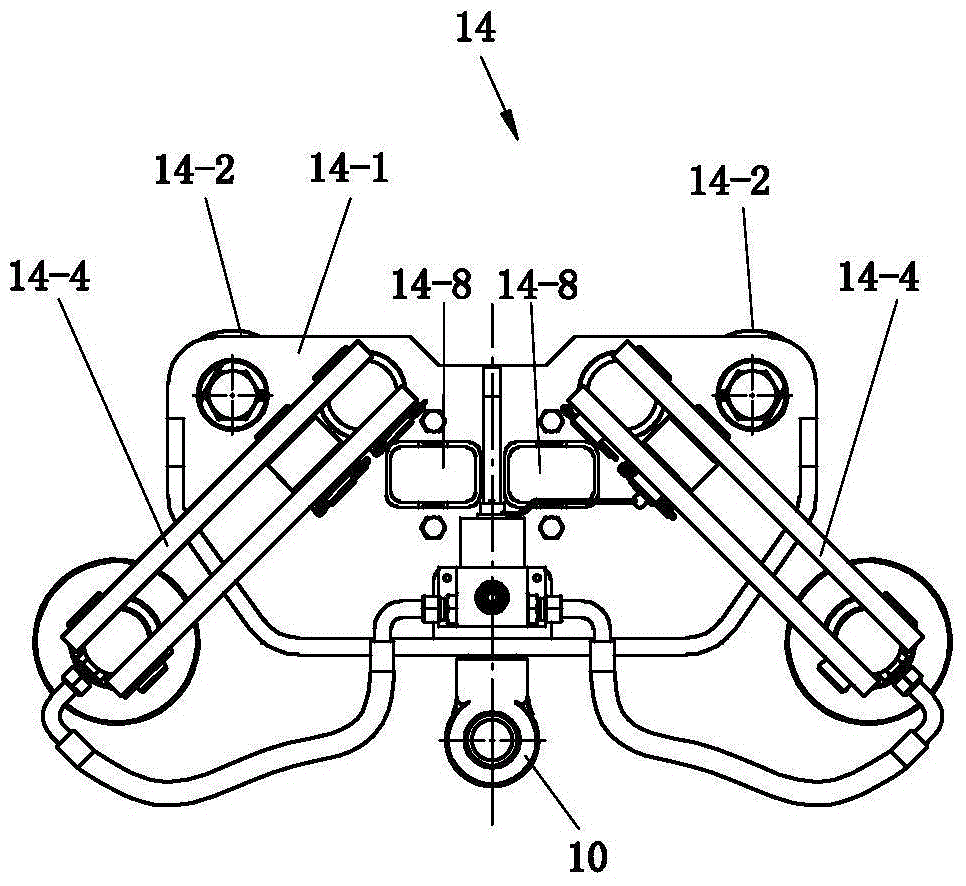

[0074] See Figure 1 to Figure 37 It is a view of the implementation of the self-driving rope traction monorail system. The present invention has a winch 11, a wire rope tensioning device 12, a tail device 5, and a suspension rail 6. The suspension rail 6 has a vehicle train running on it, and the vehicle train includes two tractors 1 and is between the two tractors 1. People's car 2, light-loaded crane 3 or / and heavy-duty crane 13, the quantity of people's car 2, light-loaded crane 3, heavy-duty crane 13 is set according to the transportation situation of mine. In this embodiment, a people carrier 2 and a light-loaded crane 3 are set between two tractors 1, between the tractor 1 and the people carrier 2 in the above-mentioned front, the people carrier and the light-loaded crane 3 All are connected by the traction link 4 between the tractor 1 between the light load crane 3 and the rear. In addition, a rope support device 7 and a pressure rope device 8 are installed on the su...

Embodiment 2

[0108] See Figure 38 , The hoisting car of the present embodiment adopts the heavy-duty hoisting car 13, and the track adopts the heavy rail track 6b, and all the other are the same as embodiment 1.

[0109] See Figure 39 to Figure 43 The heavy-duty crane 13 has two box girders 13-1, and a load-bearing beam 13-2 is respectively hinged on both sides of the top of each box girder 13-1, and a load-bearing beam 13-2 is respectively hinged on both sides of the top of each load-bearing beam 13-2. The universal carrying device 5 can also be provided with a brake carrying device 14 as required, and the universal carrying device 5 is connected to the top of the carrying beam 13-2 through a universal joint 10, and the two ends of the carrying beam 13-2 are respectively provided with bumpers. . Two adjacent load beams 13-2 on two box girders 13-1 are connected by a connecting rod 4, thereby realizing the connection of two box girders 13-1, and each box girder 13-1 The casing 13-1-1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com