Discharge nozzle of stone hoist

A hoist and stone technology, used in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of large impact on the hoarding, perforated steel plates, affecting the normal use of equipment, etc., to overcome the large impact and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

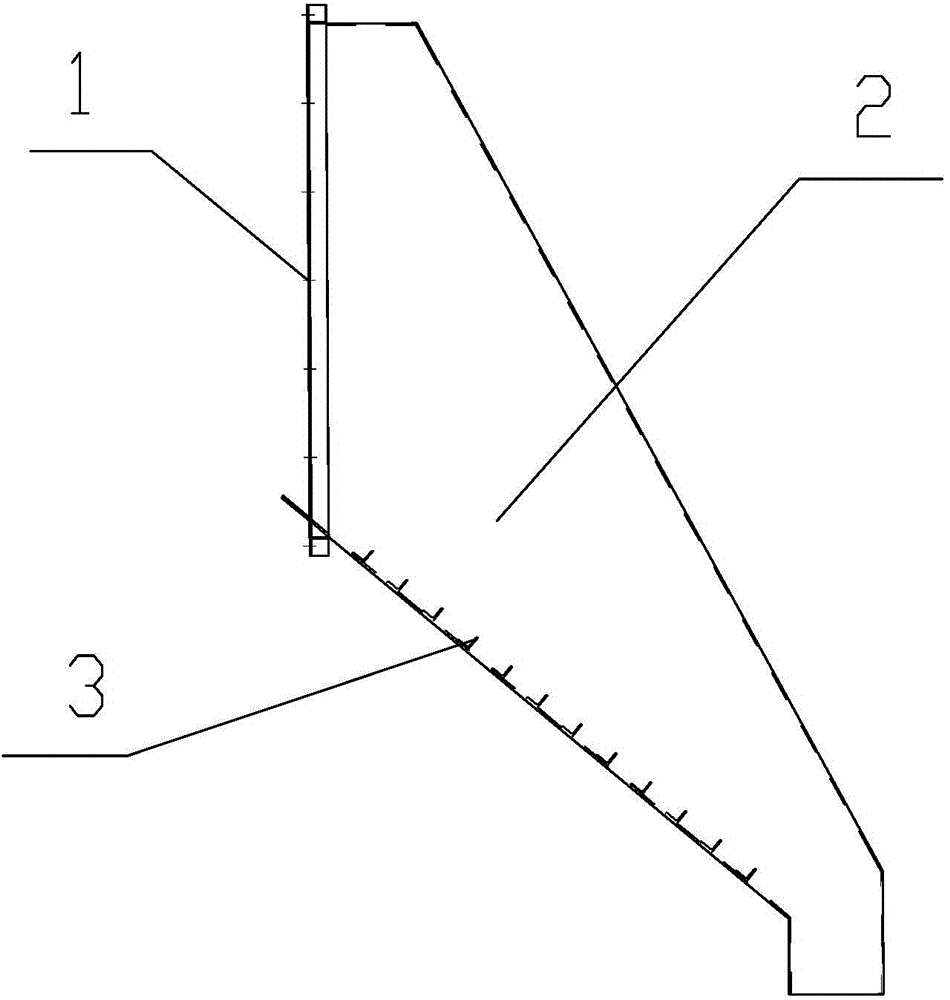

[0009] Such as figure 1 As shown: the discharging spout of the stone hoist includes a discharging spout enclosure 2 which is provided with an angle steel flange 1 at the front end; the lower end surface of the discharging spout enclosure 2 is provided with several angles 3.

[0010] The several angle steels 3 are evenly and vertically arranged on the lower end surface of the spout enclosure 2. The spacing between the angle steels 3 is 15 cm.

[0011] In the present invention, an angle steel 3 is welded every 15 centimeters on the lower end surface of the blanking spout 2 so that the stone is blocked by the angle steel 3 to form a stone isolation layer. One end surface of each angle steel is directly welded to the lower end surface of the cutting nozzle enclosure plate 2, and the direction of the angle steel is perpendicular to the direction of stone cutting.

[0012] In this way, when the stone is thrown from the hoist hopper into the discharge nozzle, several angles will form a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com