A wafer multi-station edge polishing equipment

A multi-station, edge technology, applied in the direction of grinding/polishing equipment, metal processing equipment, machine tools suitable for grinding workpiece edges, etc., can solve the problems of easy embrittlement, low yield, high wafer hardness, etc., to achieve Reduces stress, improves usability, and avoids the effect of excessive shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

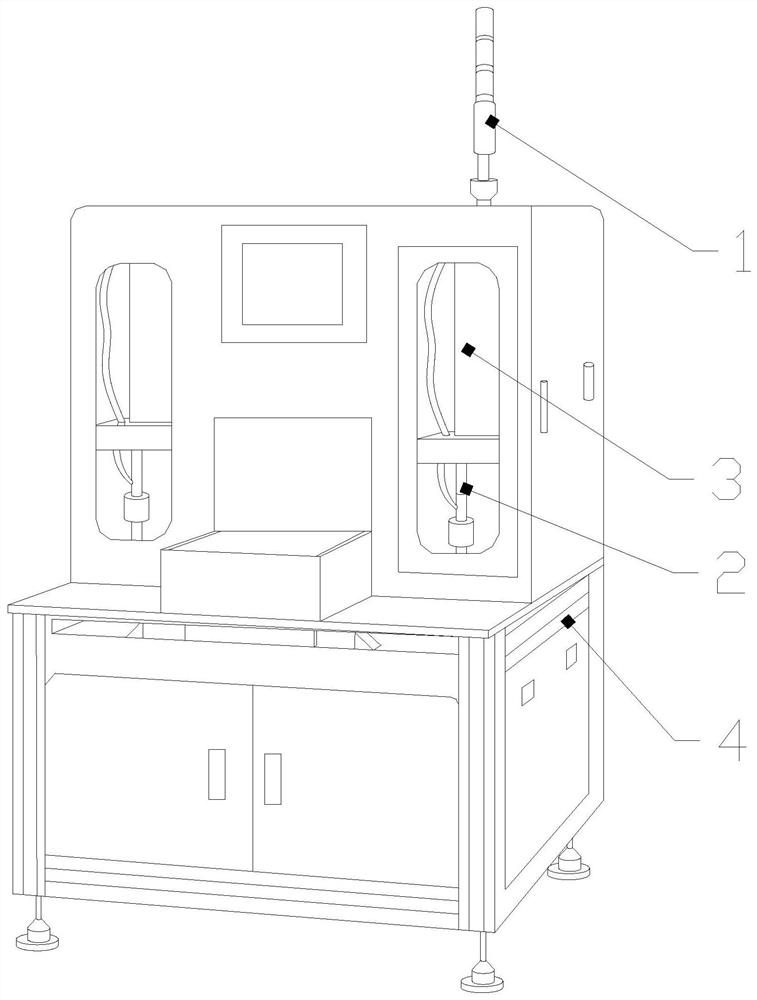

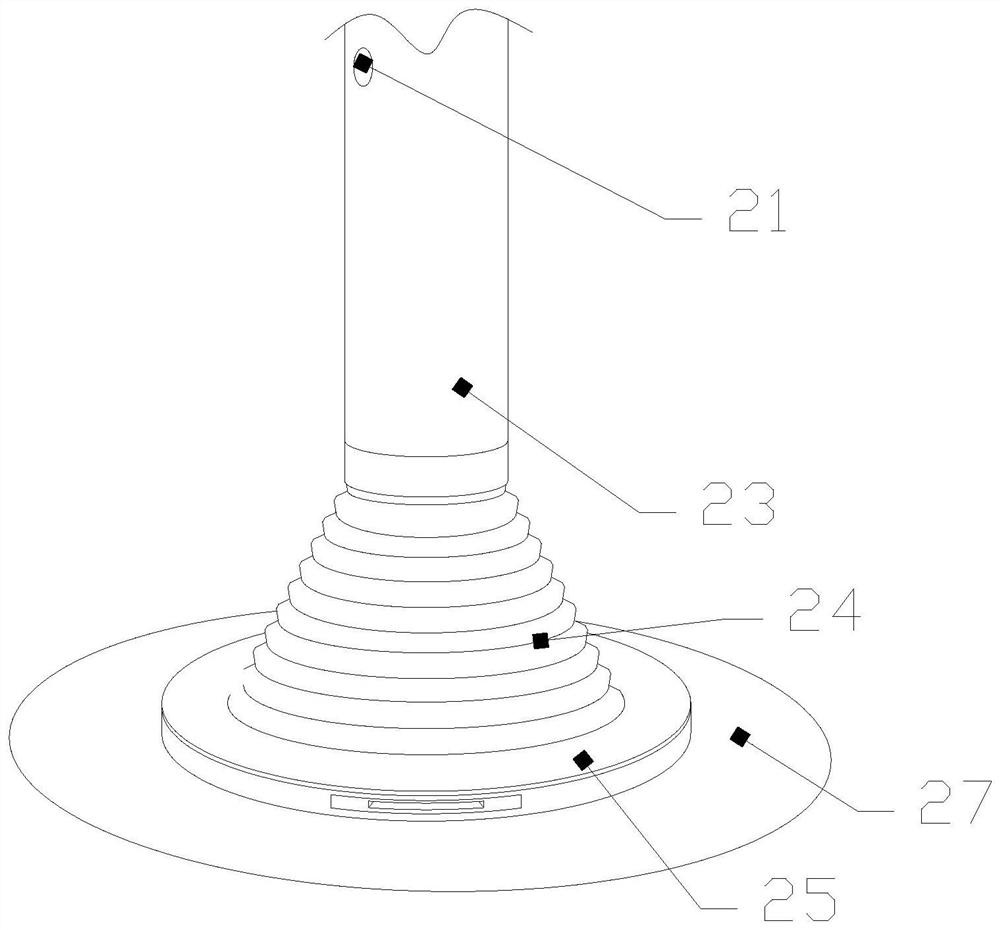

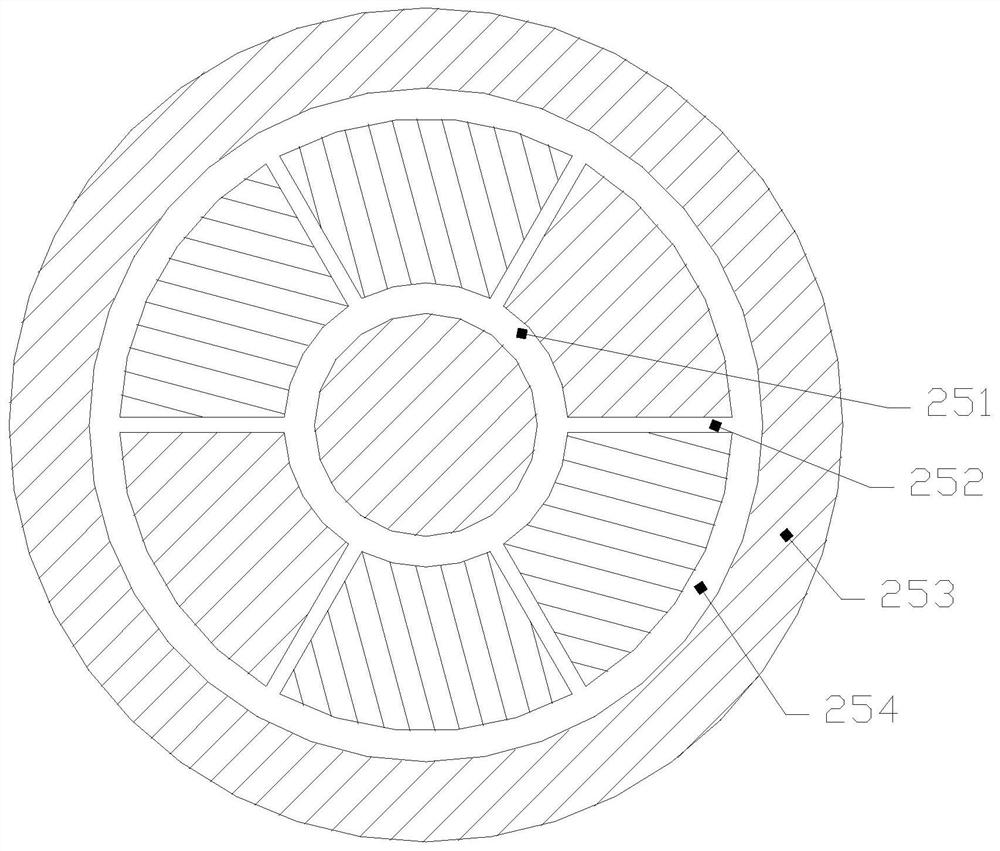

[0030] see Figure 1-Figure 4 , a wafer multi-station edge polishing equipment, the present invention provides a wafer multi-station edge polishing equipment, its structure includes a fixed rod 1, a polishing system 2, a hydraulic cylinder 3, a body 4, the top surface of the body 4 There are two polishing systems 2, and a hydraulic cylinder 3 is arranged directly above the polishing system 2, and the hydraulic cylinder 3 is mechanically connected with the polishing system 2. The top of the body 4 is provided with a fixed rod 1, and the polishing system 2 Including air inlet 21, main rod 23, folding cylinder 24, fixed plate 25, and operating platform 27, the operating platform 27 is fixed directly above the body 4, and a fixed plate 25 is arranged directly above the operating platform 27, and the fixed plate 25 is provided with a folding cylinder 24 on the top surface. The folding cylinder 24 is a hollow structure. The air outlet 21 is mechanically connected with the air inlet...

Embodiment 2

[0035] see Figure 1-Figure 8 , a wafer multi-station edge polishing equipment, the present invention provides a wafer multi-station edge polishing equipment, its structure includes a fixed rod 1, a polishing system 2, a hydraulic cylinder 3, a body 4, the top surface of the body 4 There are two polishing systems 2, and a hydraulic cylinder 3 is arranged directly above the polishing system 2, and the hydraulic cylinder 3 is mechanically connected with the polishing system 2. The top of the body 4 is provided with a fixed rod 1, and the polishing system 2 Including air inlet 21, main rod 23, folding cylinder 24, fixed plate 25, and operating platform 27, the operating platform 27 is fixed directly above the body 4, and a fixed plate 25 is arranged directly above the operating platform 27, and the fixed plate 25 is provided with a folding cylinder 24 on the top surface. The folding cylinder 24 is a hollow structure. The air outlet 21 is mechanically connected with the air inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com