High-speed batch-out, paper laying and stacking equipment for solar photovoltaic glass

A solar photovoltaic and glass technology, applied in the stacking of objects, lighting and heating equipment, and destacking of objects, etc., can solve the problems of manual adjustment of special positioning rollers, low safety factor, and unstable efficiency. The effect of saving equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

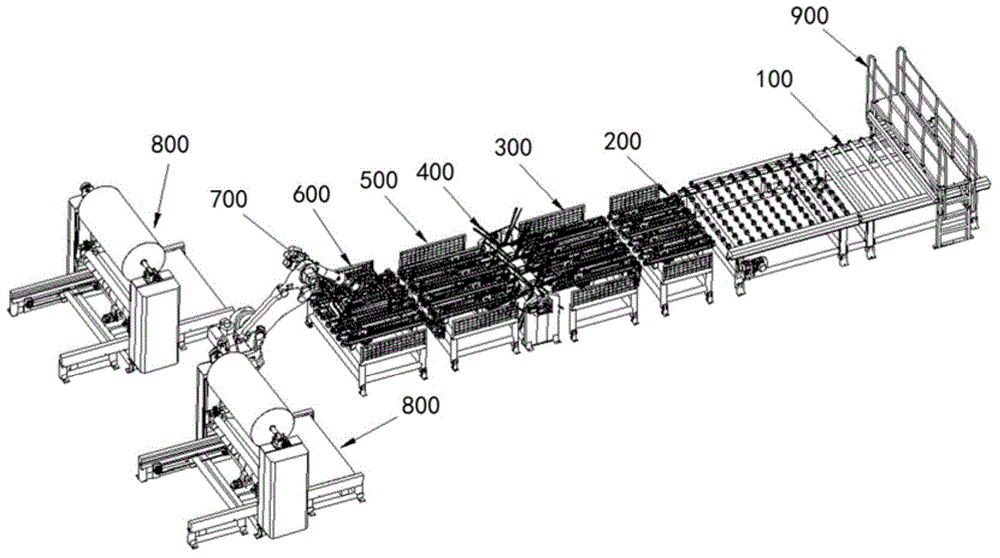

[0026] Such as figure 1 As shown, a solar photovoltaic glass high-speed sheet laying and stacking equipment includes a front conveyor frame 100 arranged in sequence, an accelerating roller conveyor frame 200, a connecting roller bracket 300 before turning over, a turning machine 400, and connecting rollers after turning over. Road 500, delivery roller table 600 and manipulator 700, a paper laying machine 800 is provided on both sides of the manipulator 700, and a bridge frame 900 is provided above the front section conveying frame 100;

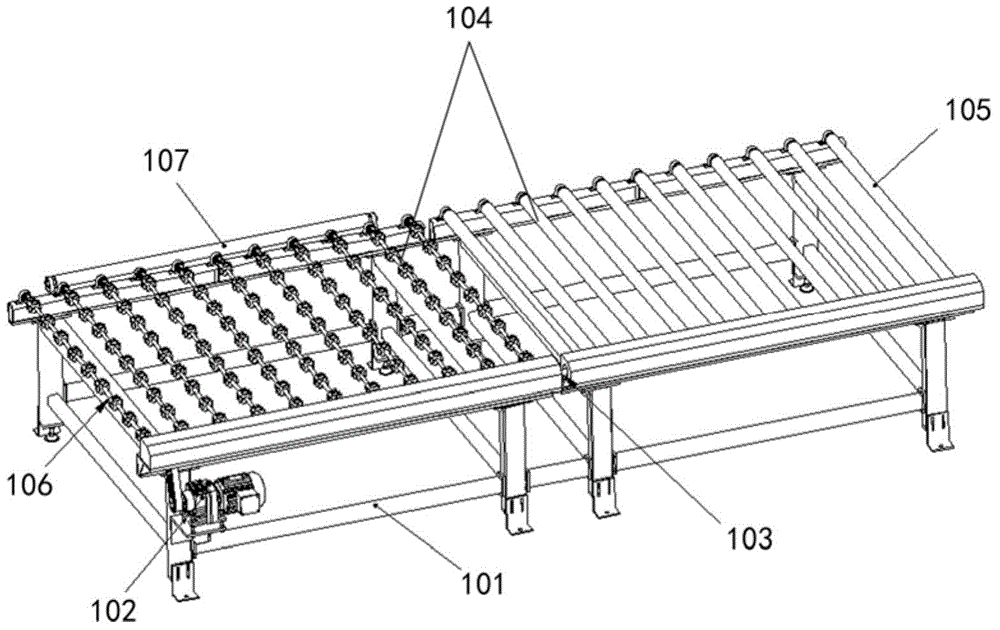

[0027] Such as figure 2 As shown, the front conveyor frame 100 includes a frame one 101, on which a drive assembly 102, a driving shaft assembly 103 and a driven shaft assembly 104 are arranged, and the driven shaft assembly 104 includes a full rubber roller conveying section 105 With the Foley wheel conveying section 106,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com