Suspension type large hanging beam

A suspension type, suspension beam technology, applied in the direction of load suspension components, transportation and packaging, etc., to achieve the effect of improving the stress condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

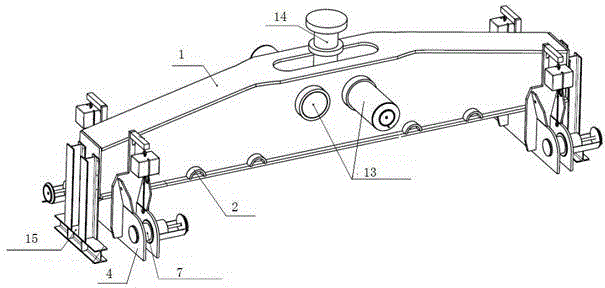

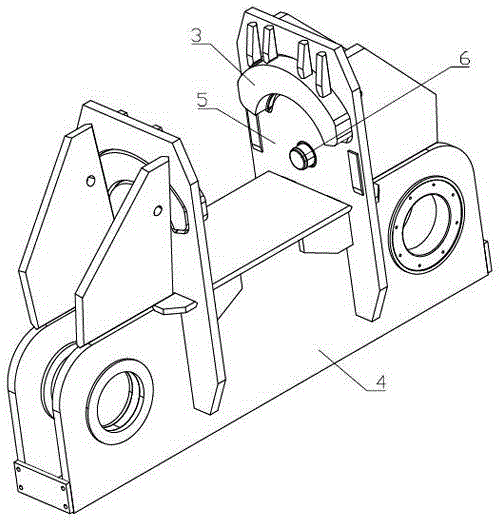

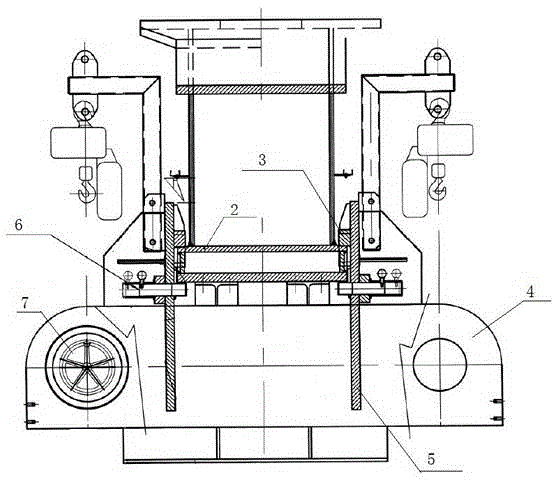

[0026] Such as figure 1 The large suspended beam shown includes a main beam 1 and two sets of suspension components arranged on the main beam 1 , and the two sets of suspension components are symmetrical to the center of the main beam 1 . The main beam 1 is provided with a suspension shaft 2 supporting the suspension assembly. The upper surface of the suspension shaft 2 is an upwardly protruding arc surface. The suspension assembly includes an upwardly protruding half-moon-shaped ear plate 3. It is press-fitted and connected to the suspension shaft 2 and forms a rotating pair with the arc surface. The arc surface of the suspension shaft 2 and the half-moon ear plate 3 form a revolving pair. On the one hand, the centering and self-positioning of the suspension assembly can be easily realized, which is convenient for the installation and adjustment of the suspension assembly. On the other hand, when the workpiece is hoisted and turned At this time, the suspension assembly can s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com