Self-compacting concrete and preparation method thereof

A self-compacting concrete and dry-mixing technology, applied in the field of building materials, can solve problems such as high cost, increased construction difficulty, unfavorable environmental protection, etc., and achieve the effect of cost reduction and good filling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

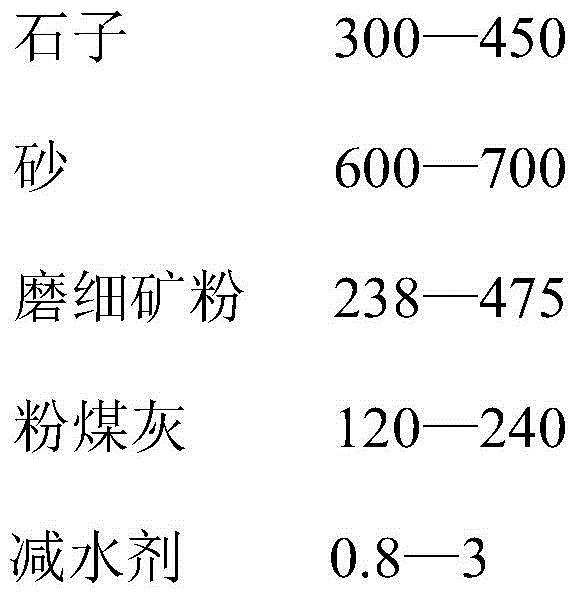

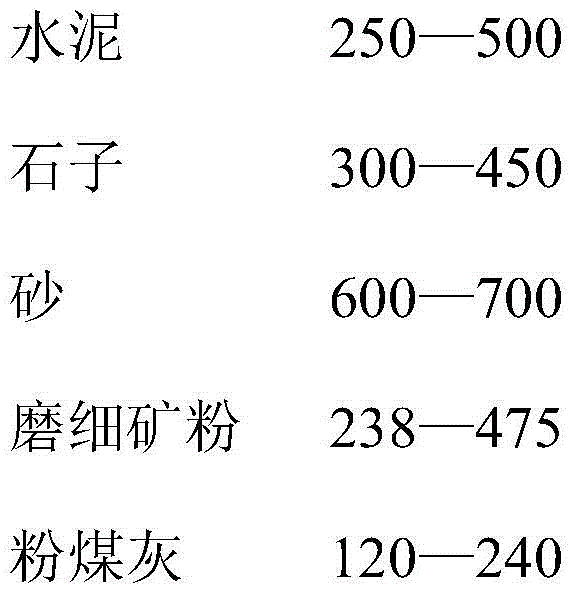

[0022] In parts by weight, weigh the following components: 250 parts of cement, 300 parts of gravel, 600 parts of sand, 238 parts of finely ground mineral powder, 120 parts of fly ash, and 0.8 parts of water reducer. 238 parts of finely ground mineral powder, 120 parts of fly ash, and 0.8 parts of water reducing agent were put into a large-scale forced mixer, stirred for 30 minutes, and then added 300 parts of stones and stirred for 50 minutes to make a dry-mixed base material for later use. , it can be transported to the construction site after being mixed with water in the mixing station, and it can also be mixed and used at the construction site.

[0023] The invention not only has good filling properties, gap passing properties, segregation resistance and stability, but also is more environmentally friendly during preparation and reduces the cost of concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com