Blending main building structure

A main building and column foot technology, applied in the direction of roads, road repair, roads, etc., can solve the problems of complex installation structure, high cost, high pressure that the column foot can bear, etc., and achieve a simple, compact and stable installation structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific drawings and embodiments.

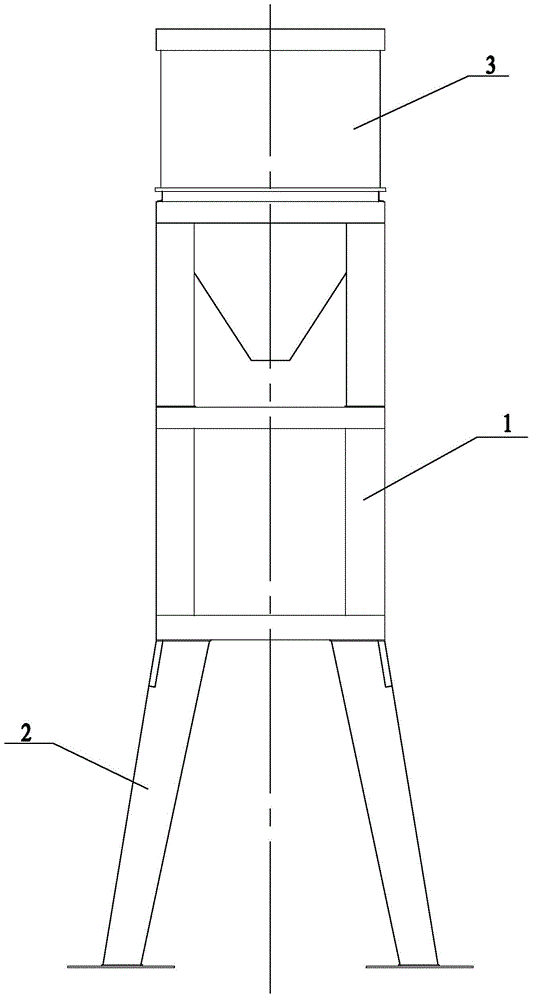

[0010] Such as figure 1 Shown: In order to reduce the installation cost, improve the lateral bearing capacity of the column feet, and ensure the reliability of the mixing main building, the present invention includes the mixing main building body 1 and the column foot body located at the lower end of the mixing main building body 1; The lower end of the mixing main building body 1 is provided with two pairs of column feet, and the two columns in each pair of column feet are in a figure-eight shape.

[0011] Specifically, the mixing main building body 1 is installed and fixed by the eight-shaped column foot 2, which not only ensures that it can withstand greater pressure, but also strengthens the bearing of the lateral force of the equipment, making the installation of the mixing main building more stable and not easy to shake. Simultaneously also do not need e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com