Control system for movable formwork template

A technology of moving formwork and control system, applied in the direction of fluid pressure actuating device, servo motor, servo motor assembly, etc. The effect of avoiding deformation or even damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

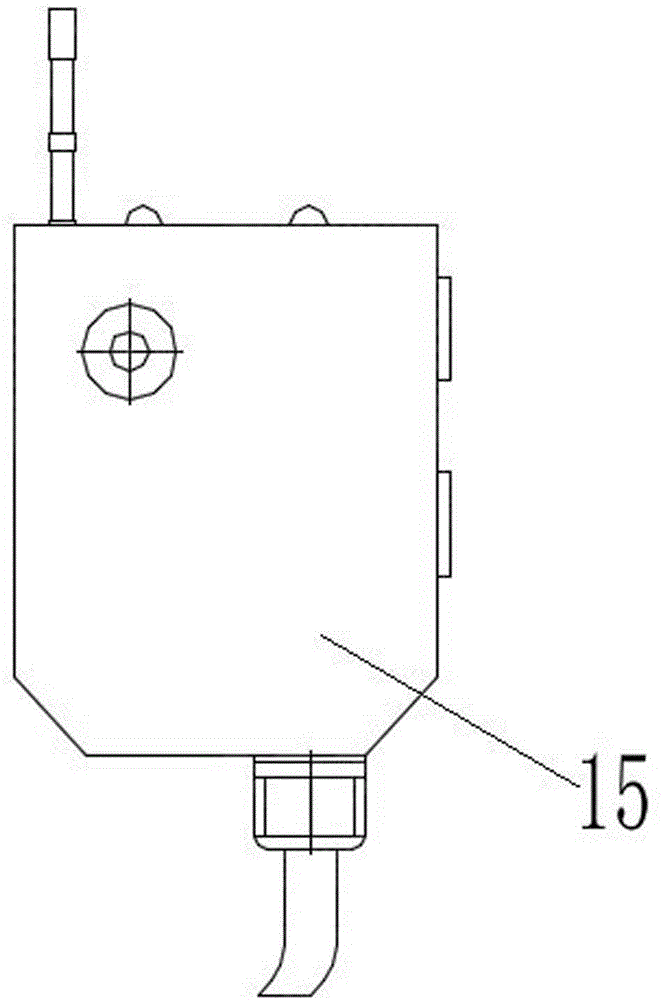

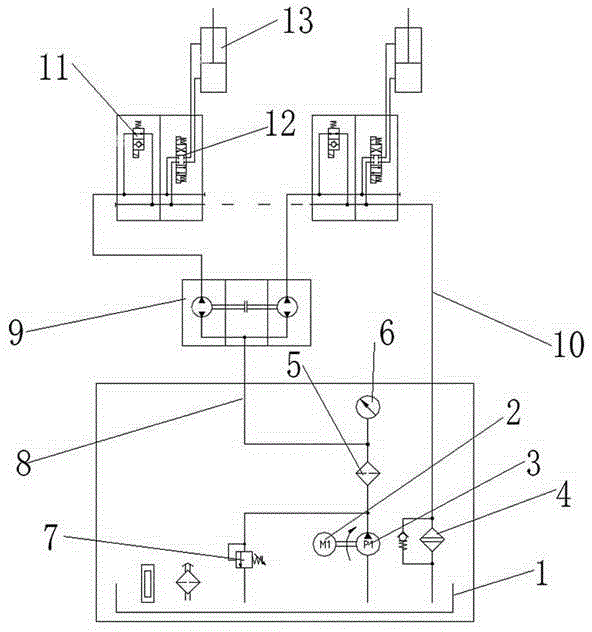

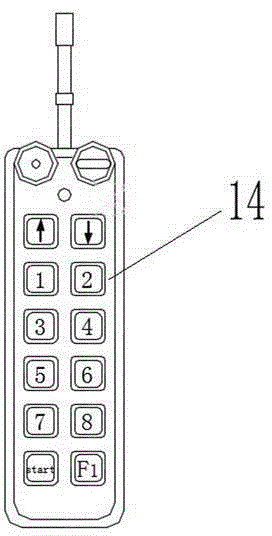

[0017] Attached below figure 1 , attached figure 2 , attached image 3 The present invention will be further described.

[0018] as attached figure 1 As shown, the mobile formwork template control system includes

[0019] The hydraulic station consists of a fuel tank 1, an oil pump 3 whose inlet is connected to the fuel tank 1 through a fuel pipe, a motor 2 installed on the oil pump 3, and a relief valve 7 connected to the outlet of the oil pump 3. The outlet of the oil pump 3 is connected through a filter 5 Pressure gauge 6 and oil inlet pipe 8; Hydraulic synchronous motor 9, its inlet end is connected with oil inlet pipe 8; The inlet port is connected to each outlet port of the hydraulic synchronous motor 9 , and the other inlet port is connected to the oil tank 1 through the oil return pipeline 10 . After the system pressure is adjusted through the overflow valve 7, the oil pump 3 operates after the motor 2 is started, and the hydraulic oil is extracted from the oil t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com