A circulating fluidized bed boiler capable of suppressing the formation of a combustion high temperature zone and its suppression method

A circulating fluidized bed and combustion suppression technology, which is applied in the direction of combustion methods, fluidized bed combustion equipment, and fuel burned in a molten state, can solve the problems of low ignition temperature of biomass fuel, increased cost of desulfurization and denitrification, and impact on water wall replacement. Thermal effects and other issues, to achieve the effect of prolonging the combustion stroke, ensuring environmental protection characteristics, and alleviating concentrated heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

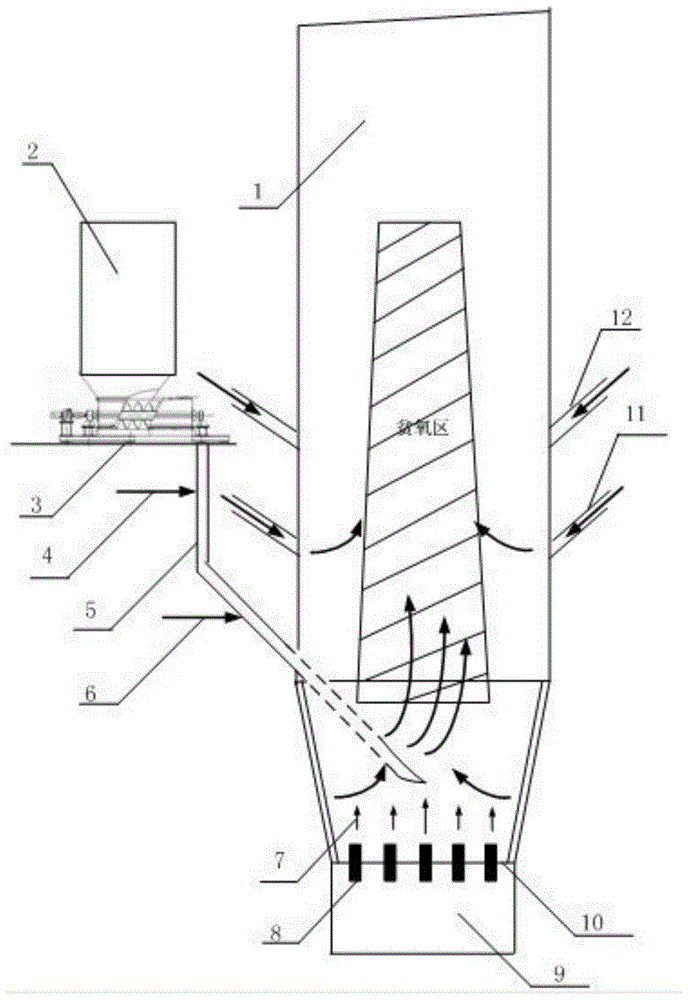

[0023] In this embodiment, a circulating fluidized bed boiler capable of suppressing the formation of a high-temperature zone of combustion includes a feeding system, and the feeding system includes a biomass fuel feeding bin 2, an outlet of the biomass fuel feeding bin 2 and a screw feeding The inlet of the feeder 3 is connected, the outlet of the screw feeder 3 is connected with the inlet of the feeding pipe 5, and the feeding opening of the feeding pipe 5 extends from the furnace wall of the furnace 1 to the center of the bottom of the furnace 1 in the depth direction, and the end adopts a circular arc Transition and upward tilting, this setting can make the biomass fuel diffuse upward along the depth center after entering the furnace; it also includes primary air and secondary air, the primary air is set at the bottom of the furnace 1, and the secondary air includes setting at the bottom of the discharge pipe 5 The sealing air 4 and the seeding air 6 at the place, and the l...

Embodiment 2

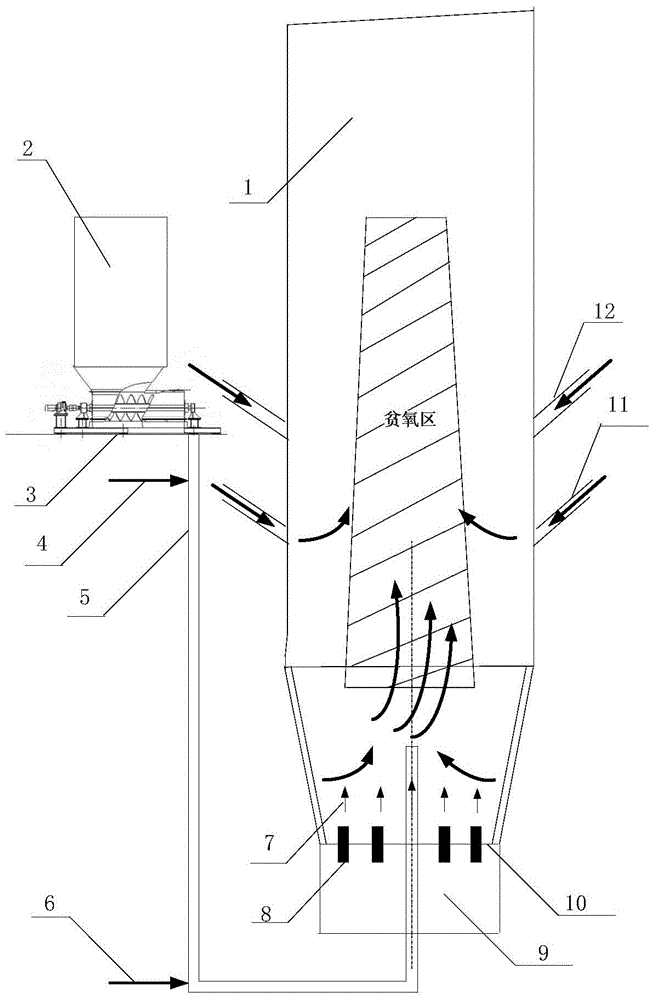

[0030] Such as figure 2 As shown, the present embodiment is a kind of circulating fluidized bed boiler that can suppress the formation of high temperature zone of combustion, same as that of embodiment one figure 1 The difference is that: the drop pipe 5 extends through the primary air chamber 8 and the air distribution plate 10 to the center of the bottom of the furnace 1 in the depth direction. The other structures and the method for suppressing the formation of the combustion high temperature zone are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com