Solid fuel high-temperature oxygen-deficient combustion method and device

A technology of lean oxygen combustion and solid fuel, which is applied in the direction of solid fuel combustion, combustion methods, and combustion equipment. It can solve the problems of excessive nitrogen oxide emissions, insufficient fuel combustion, and uneven temperature field. Balanced volume amplification, improved equipment life, and uniform temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

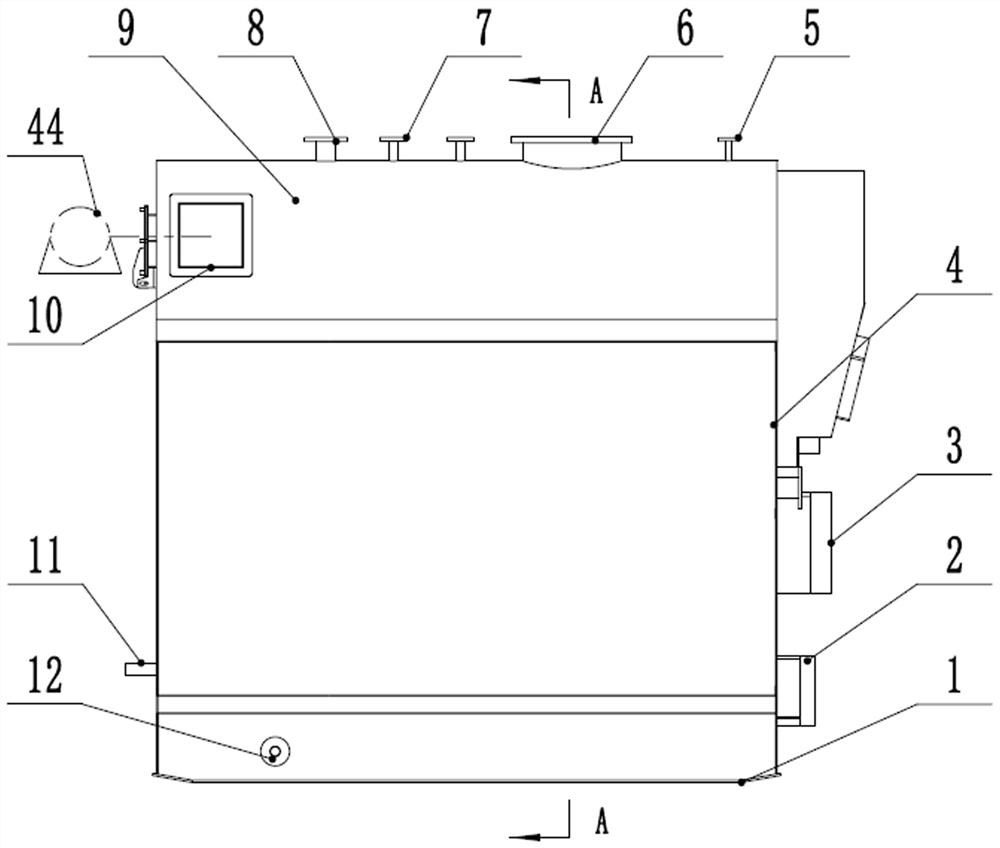

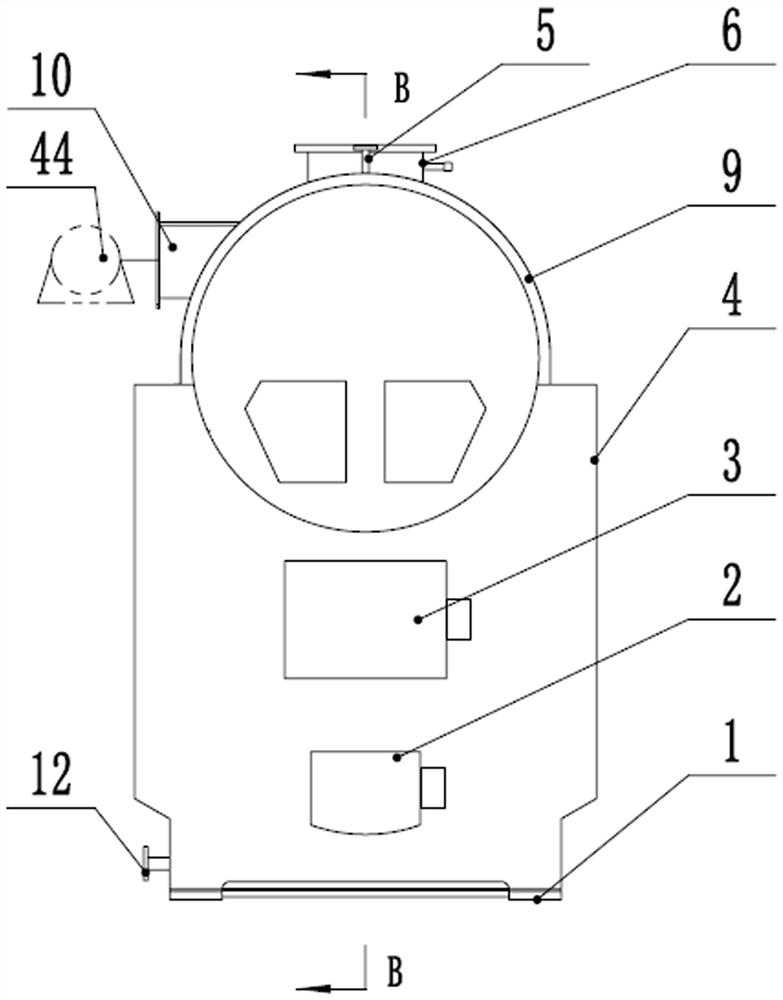

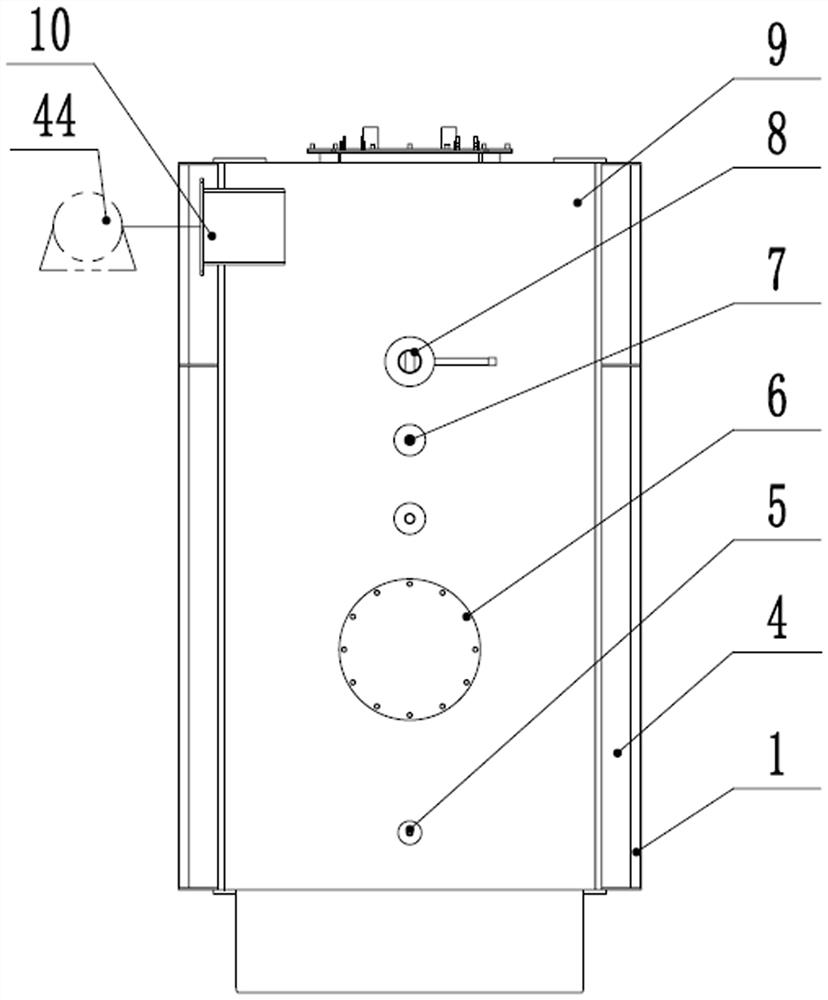

[0042] A high-temperature oxygen-deficient combustion method for solid fuel, which is a process of burning solid fuel in a high-temperature oxygen-deficient combustion device for solid fuel; the furnace of the high-temperature oxygen-deficient combustion device is provided with a layered combustion grate and a high-temperature oxygen supplement for the furnace chamber The lower part of the furnace communicates with the lower part of the gas combustion chamber through the burner; the burner is connected with an oxygen supply pipe for supplementing the burner with oxygen; the high-temperature oxygen-poor combustion device is divided into three interlinked combustion zones, the first combustion zone is Solid fuel semi-gasification combustion zone, which is above and below the layer combustion grate; the second combustion zone is the carbon and gas combustion zone, which is under the layer combustion grate and the area between the burner; the third combustion zone is gas combustion ...

Embodiment 2

[0045] A high-temperature oxygen-deficient combustion method for solid fuel, which is a process of burning solid fuel in a high-temperature oxygen-deficient combustion device for solid fuel; the furnace of the high-temperature oxygen-deficient combustion device is provided with a layered combustion grate and a high-temperature oxygen supplement for the furnace chamber The lower part of the furnace communicates with the lower part of the gas combustion chamber through the burner; the burner is connected with an oxygen supply pipe for supplementing the burner with oxygen; the high-temperature oxygen-poor combustion device is divided into three interlinked combustion zones, the first combustion zone is Solid fuel semi-gasification combustion zone, which is above and below the layer combustion grate; the second combustion zone is the carbon and gas combustion zone, which is under the layer combustion grate and the area between the burner; the third combustion zone is gas combustion ...

Embodiment 3

[0054] A high-temperature oxygen-deficient combustion method for solid fuel, which is a process of burning solid fuel in a high-temperature oxygen-deficient combustion device for solid fuel; the furnace of the high-temperature oxygen-deficient combustion device is provided with a layered combustion grate and a high-temperature oxygen supplement for the furnace chamber The lower part of the furnace communicates with the lower part of the gas combustion chamber through the burner; the burner is connected with an oxygen supply pipe for supplementing the burner with oxygen; the high-temperature oxygen-poor combustion device is divided into three interlinked combustion zones, the first combustion zone is Solid fuel semi-gasification combustion zone, which is above and below the layer combustion grate; the second combustion zone is the carbon and gas combustion zone, which is under the layer combustion grate and the area between the burner; the third combustion zone is gas combustion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com