Low-temperature valve airtightness test device

A test device and air-tightness technology, which is applied in the direction of liquid-tightness measurement using liquid/vacuum degree, etc. It can solve the problems that the valve sealing performance cannot meet the process requirements, the valve sealing surface is not clean, and the thread of the valve body is easy to be damaged. , to achieve the effect of convenient and quick maintenance, reduced test cost and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The best embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

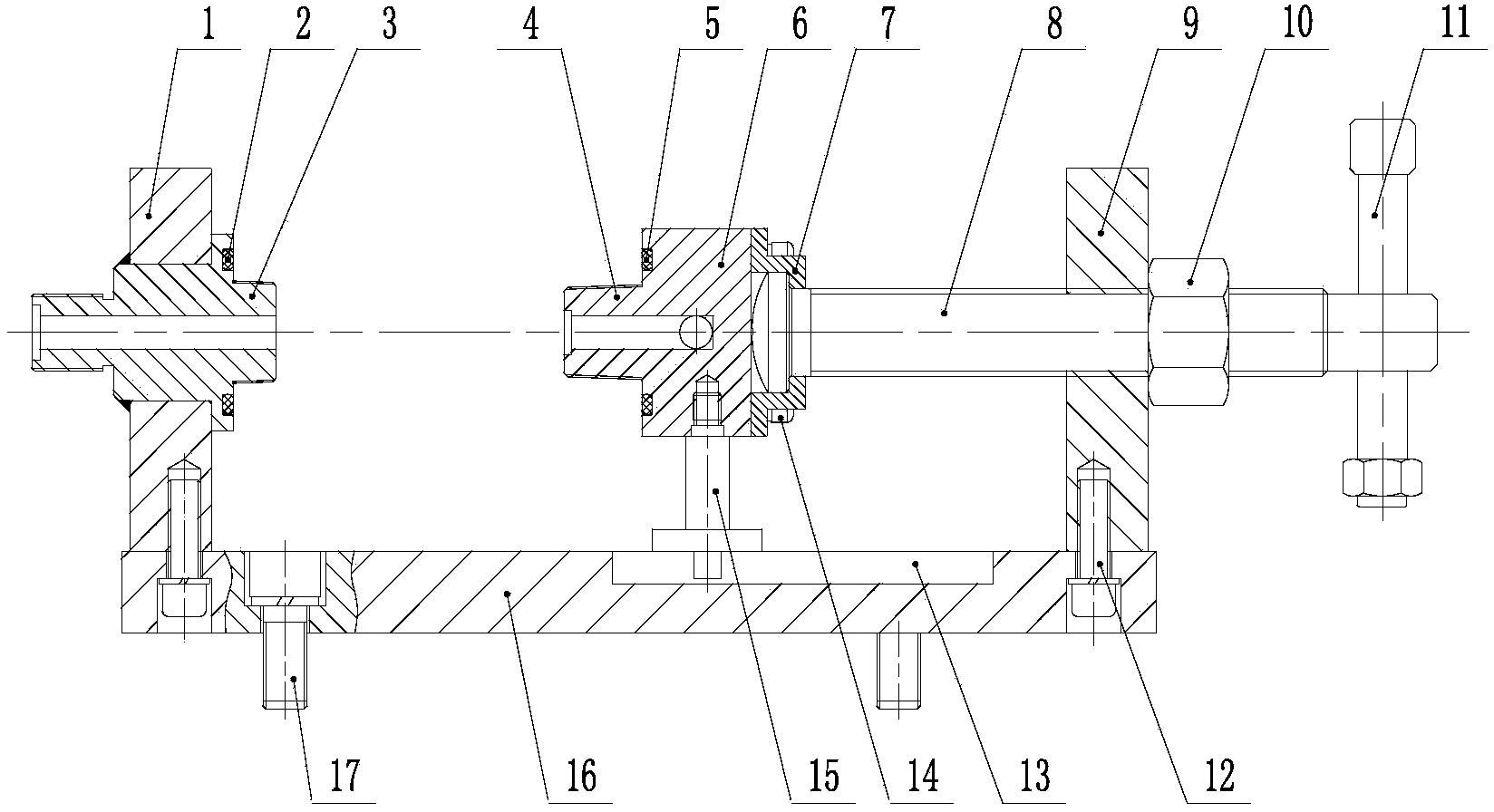

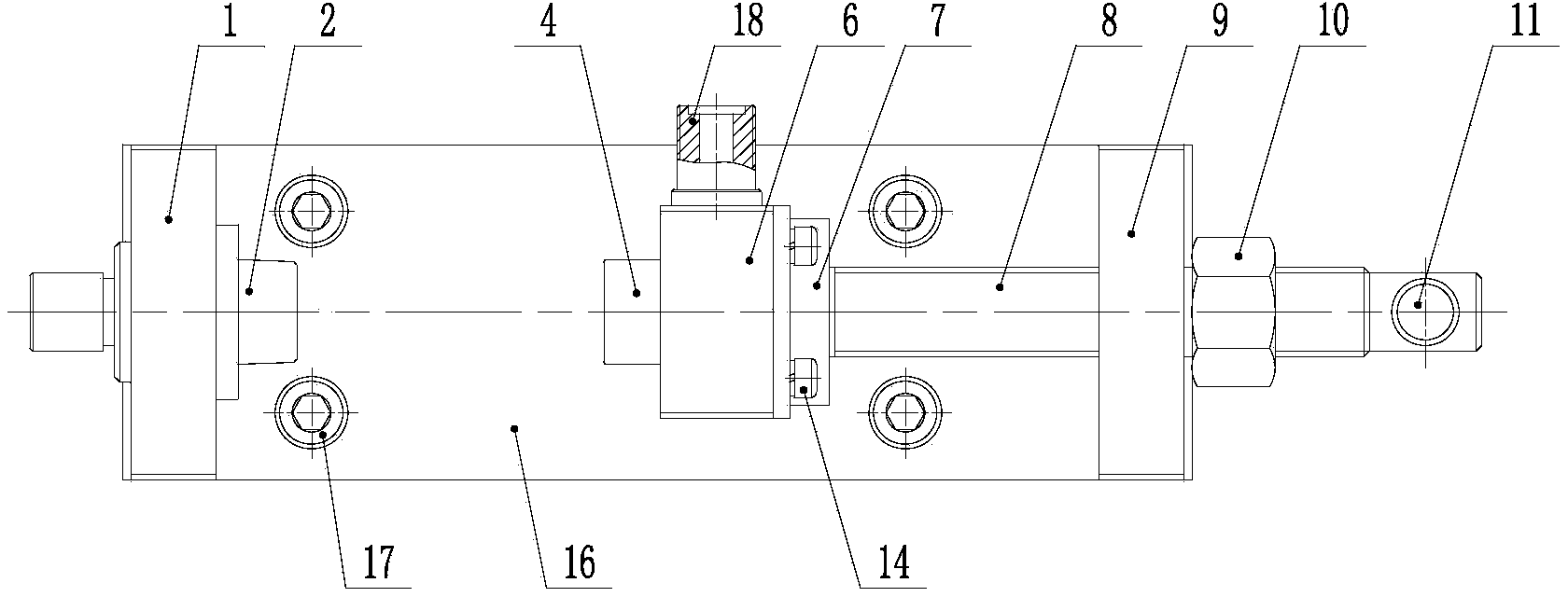

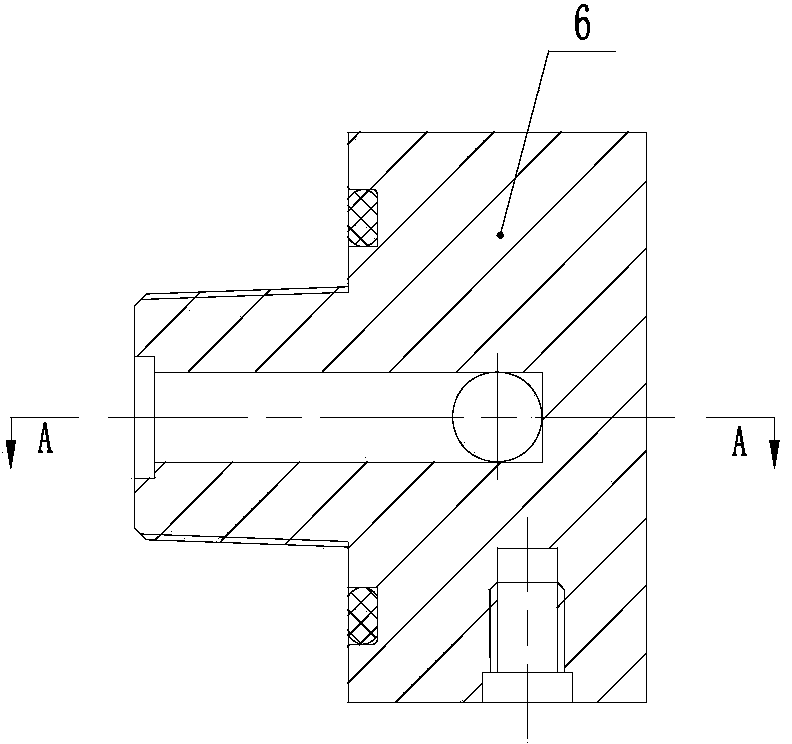

[0035] See attached figure 1 , 2 , A cryogenic valve air tightness test device, which includes left vertical plate 1, O-ring Ⅰ2, inlet joint 3, outlet joint 4, O-ring Ⅱ5, compression seat 6, end cover 7, mandrel 8 , Right vertical plate 9, lock nut 10, handle 11, connecting bolt I12, guide groove 13, connecting bolt II14, support shaft 15, bottom plate 16, connecting bolt III17, outlet joint 18.

[0036] See attached figure 1 , 2 , The left vertical plate 1 is provided with a smooth opening with the same outer diameter size as the inlet connector 3.

[0037] The right vertical plate 9 is provided with a threaded hole consistent with the top rod 8.

[0038] The upper end surface of the bottom plate 16 is provided with a longitudinal guide groove 13.

[0039] The left vertical plate 1 and the right vertical plate 9 are respectively fixed to the symmetrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com