Impact testing machine for deck chair handrail

A technology of impact testing machine and handrail, which is applied in the direction of impact testing, machine/structural component testing, measuring devices, etc. It can solve the problems of structural redundancy, immature technology, and inability to form industrialization, etc., and achieve convenient and safe testing strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

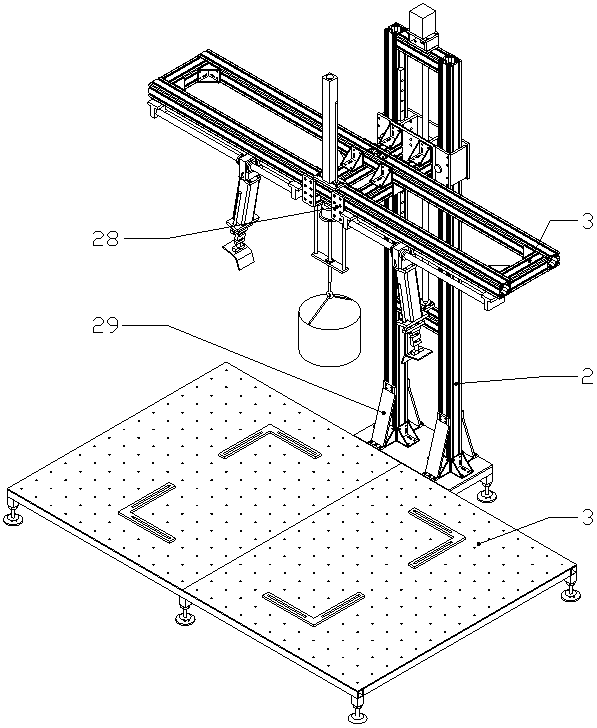

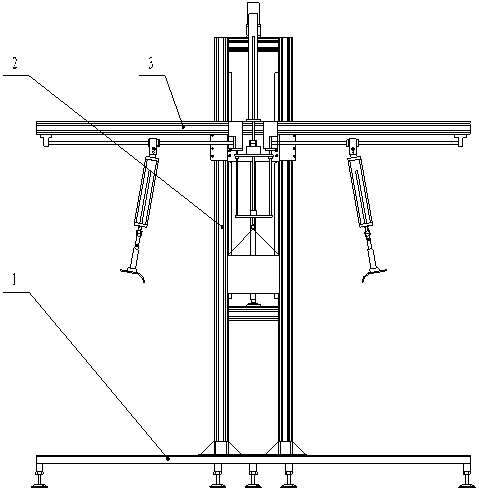

[0018] see figure 1 , the recliner armrest impact testing machine includes a base part (1), a column part (2) and a loading part (3); it is characterized in that: the loading part (3) is fixedly installed on the column part (2 ) on the loading part connecting plate (28) is connected with the column part (2); the column part (2) is connected with the base part (1 )connect.

Embodiment 2

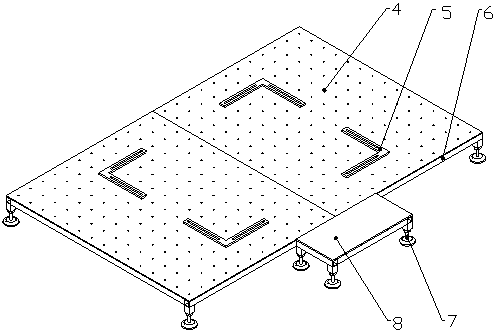

[0020] see figure 1 , figure 2 , image 3 and Figure 4 , this embodiment is basically the same as Embodiment 1, and the special features are as follows: the base part (1) includes two bottom plates (4) with threaded holes on them, a fixed block (5), and an aluminum alloy bottom frame (6) , eight with screw feet (7) and column bottom plates (8); the bottom plates (4) and column bottom plates (8) are fixed to the aluminum alloy bottom frame (6) by screws; the feet (4) pass The self-contained screw rod is adjustable connected with the aluminum alloy bottom frame (6); the fixed block (5) is fixed on the bottom plate (4) by screws.

[0021] The column component (2) includes a sandbag fixing horizontal plate (9), a sandbag guide rod (10), an impact loading fixing block (11), a cantilever beam profile (12), a lifting platform separation plate (13), and a lifting platform front plate (14), screw motor (15), coupling (16), screw motor seat bearing cover (17), screw motor seat mid...

Embodiment 3

[0024] see figure 1 , figure 2 , image 3 and Figure 4 , the armrest durability test of the recliner is carried out by using the above-mentioned recliner armrest impact testing machine: put the recliner on the bottom plate (4) first, adjust the fixed block (5) on the bottom plate to limit the position of the recliner; adjust the left and right guide rod limit blocks to make the armrest The loading part (30) touches the armrest of the recliner in the horizontal direction (if there is a sandbag on the suspension ring, remove the sandbag (39)); loosen the locking device (23) and start the screw motor (15), so that the armrest loading part (30) When moving up and down in the vertical direction, the fatigue test can be carried out to the armrest of the reclining chair; finally, the locking device (23) can be tightened, and the durability test of the armrest of the reclining chair can be carried out after checking each component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com