All-dry parallel wiring cable

A parallel wiring, all-dry technology, applied in the directions of light guides, optics, optical components, etc., can solve the problems of occupying a lot of resources, not having waterproofing, and large outer diameter of optical cables, so as to occupy less pipeline resources, save wiring space, and optical cables. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

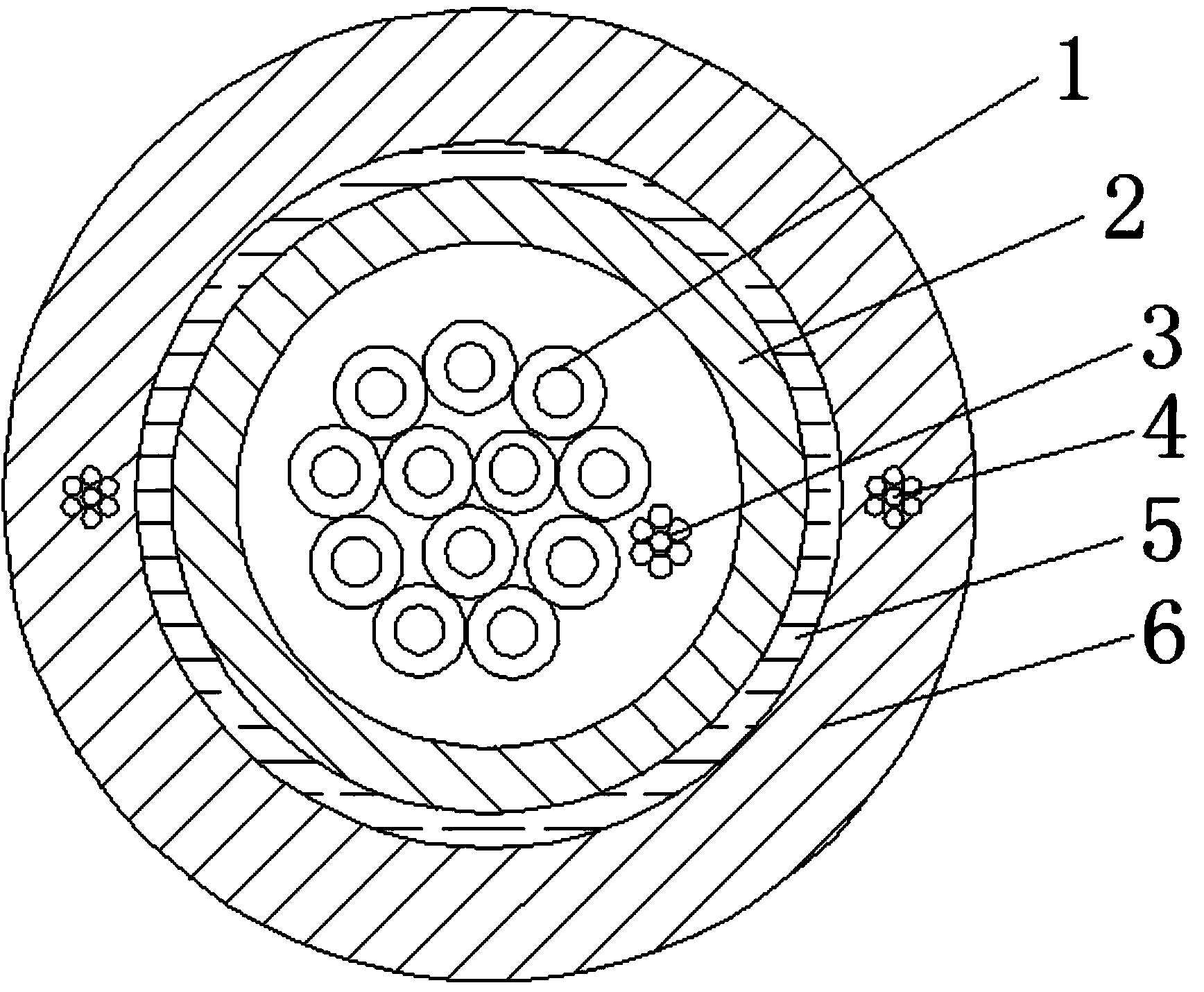

[0015] refer to figure 1 , the specific embodiment adopts the following technical solutions: a fully dry parallel wiring optical cable, including optical fiber 1, loose tube 2, water blocking yarn 3, galvanized steel strand 4, aramid fiber 5 and outer sheath 6, loose The inside of the casing 2 is provided with an optical fiber 1, and the water-blocking yarn 3 is filled between the optical fiber 1 and the loose tube 2, the outer layer of the loose tube 2 is longitudinally covered with aramid fiber 5, and the loose tube 2 is arranged inside the outer sheath 6 , the aramid fiber 5 is set between the loose tube 2 and the outer sheath 6, the aramid fiber 5 is resistant to acid and alkali, and the insulation is anti-aging, which ensures the ultra-high strength and service life of the optical cable; the outer sheath 6 is symmetrically embedded with galvanized Strand 4.

[0016] It is worth noting that the number of cores of the optical fiber 1 is 12 cores, the optical fiber 1 adopts...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap