Backlight module and display device

A backlight module and display device technology, applied in light guides, optics, optical components, etc., can solve problems such as low utilization rate of light sources, light decay of light sources affecting product display quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

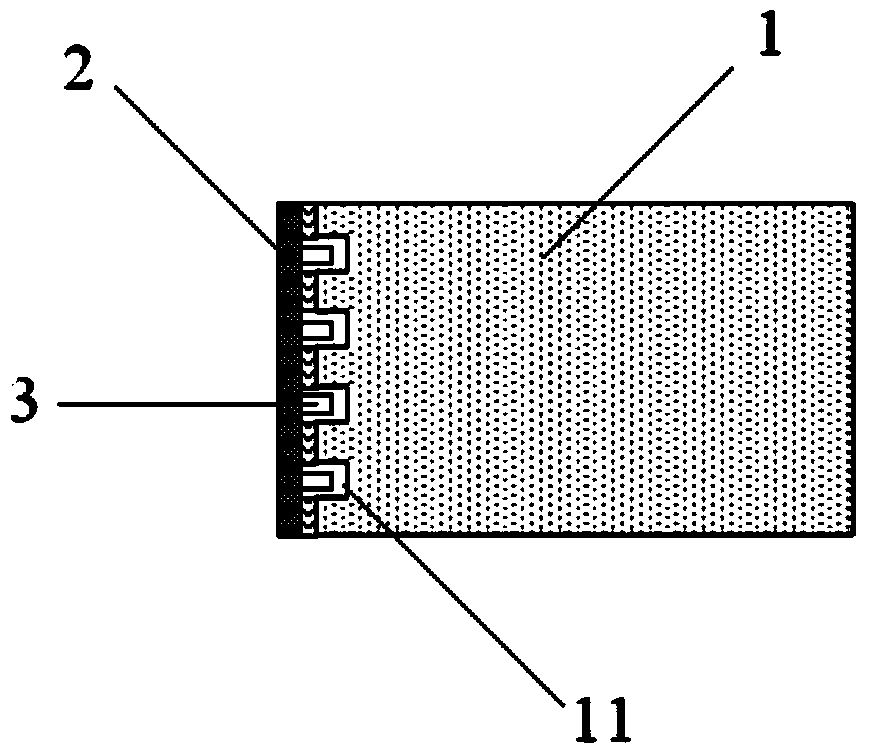

[0031] Such as Figure 1~4 As shown, the present invention provides a backlight module, which includes:

[0032] The light guide plate 1 and the PCB substrate 2 located on both sides of the light guide plate 1, the PCB substrate 2 is provided with several light source devices 3;

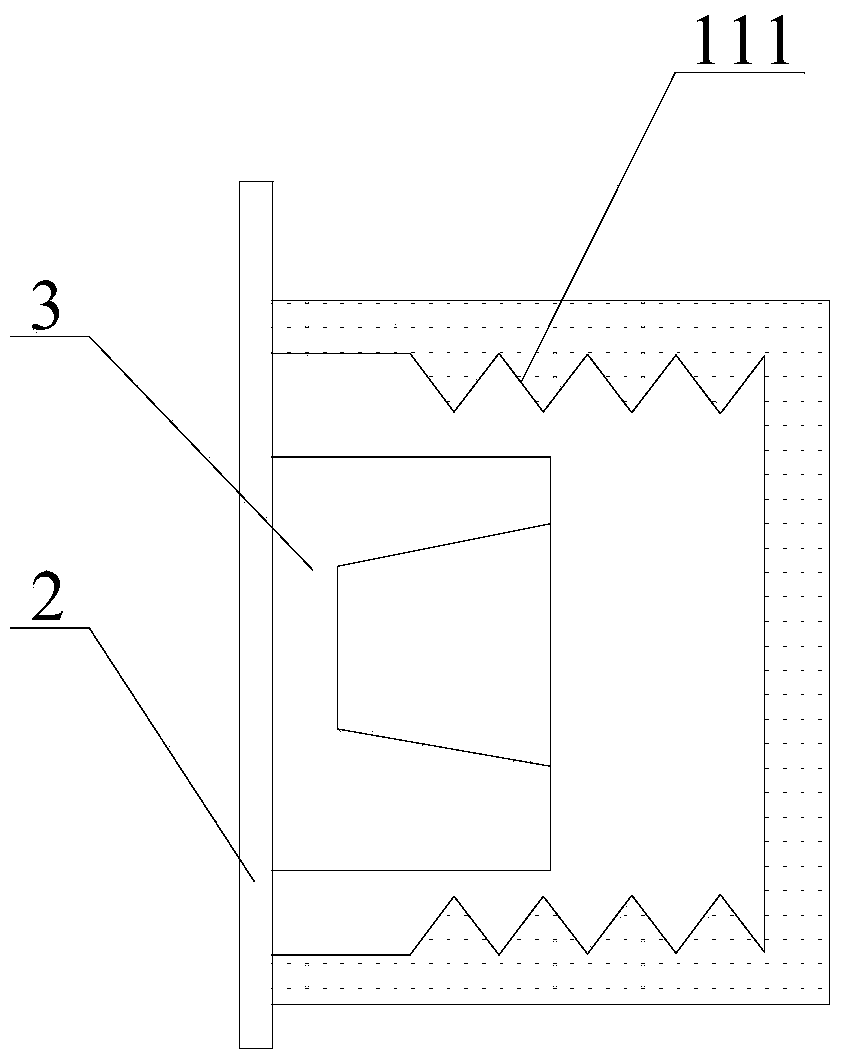

[0033] Two sides of the light guide plate 1 facing the PCB substrate 2 are provided with several grooves 11 for accommodating the light source device 3; two opposite inner walls of the groove 11 are provided with several protrusions 111.

[0034] The protrusion 111 is made by the light guide plate 1 and is directly formed on the inner wall of the groove 11 . That is, when the groove 11 is formed on the light guide plate 1 , the pattern of the protrusion 111 is also formed.

[0035] In this embodiment, the two sides of the light guide plate are arranged in a groove structure, which can better accommodate the light source device, save the occupied area of the light source device to the greatest ext...

Embodiment 2

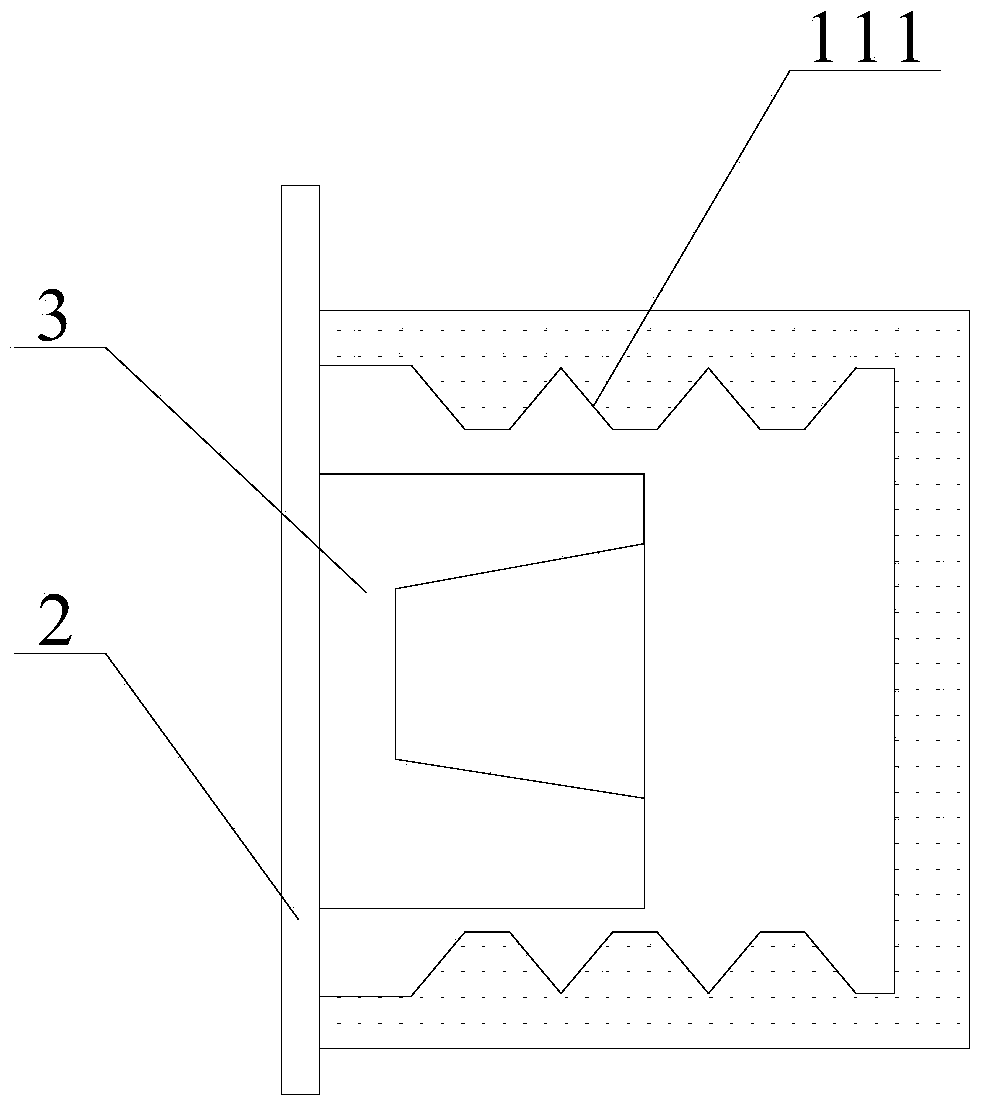

[0045] Such as Figure 5 As shown, the difference between the backlight module provided in this embodiment and the first embodiment is that the protrusion 111 is made of a lens film, and the lens film is pasted on two opposite inner walls of the groove 11 . That is, it is enough to form the groove 11 on the light guide plate 1 , and the lens film is pasted on the two opposite inner walls of the groove by sticking the lens film.

[0046] Similarly, the lens film can also be polygonal or arc-shaped, the polygon can be triangle and quadrangle, and the quadrangle can be rectangle, trapezoid or other irregular quadrilateral;

[0047] The arc can be a semicircle, a semi-ellipse, or other irregular arcs.

[0048] The lens film can use different shapes as protrusions of different shapes to further reflect more light and improve the effective use of light.

[0049] On the other hand, the present invention also provides a display device, comprising the above-mentioned backlight module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com