An image detection method for surface defects of silicon steel plate under the interference of oil pollution

A technology of image detection and silicon steel plate, applied in image enhancement, image analysis, image data processing, etc., can solve the problems of target information coverage, increase the difficulty of target detection and recognition, and achieve the effect of avoiding false edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

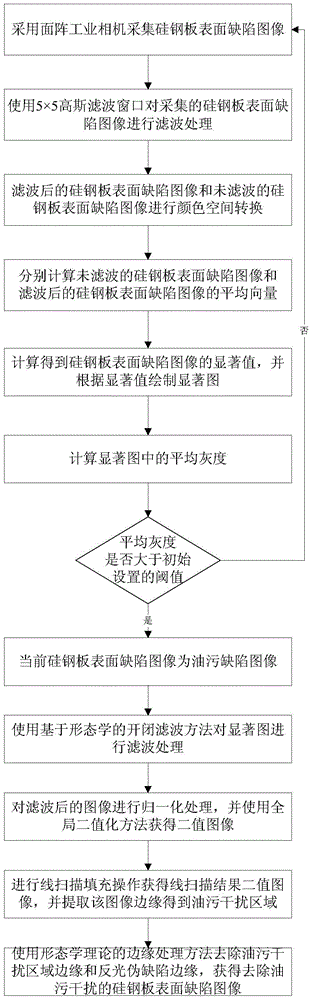

[0038] An image detection method for surface defects of silicon steel sheets under oil pollution interference, such as figure 1 shown, including the following steps:

[0039] Step 1. Use an area array industrial camera to collect the surface defect image of the silicon steel plate;

[0040] Step 2, using a visual saliency method to detect defects on the collected silicon steel sheet surface defect images;

[0041] Step 2-1, using a 5×5 Gaussian filter window to filter the collected silicon steel plate surface defect image;

[0042] Step 2-2, performing color space conversion on the silicon steel plate surface defect image filtered in step 2-1 and the unfiltered silicon steel plate surface defect image, that is, from RGB color space to Lab color space;

[0043] Step 2-3, in the Lab color space, respectively calculate the avera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com