Ultra wide band bridge based on thick film manufacturing technology

A manufacturing process and ultra-broadband technology, applied in the direction of circuits, electrical components, connecting devices, etc., can solve the problems of low-frequency applications of megahertz and below and high-frequency applications above 10GHz, bridge performance constant-ratio power-dividing characteristics and bar It can solve the problems such as the great influence of the thermal balance characteristics, and achieve the effects of high power capacity and antistatic ability, good phase consistency, and high engineering practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

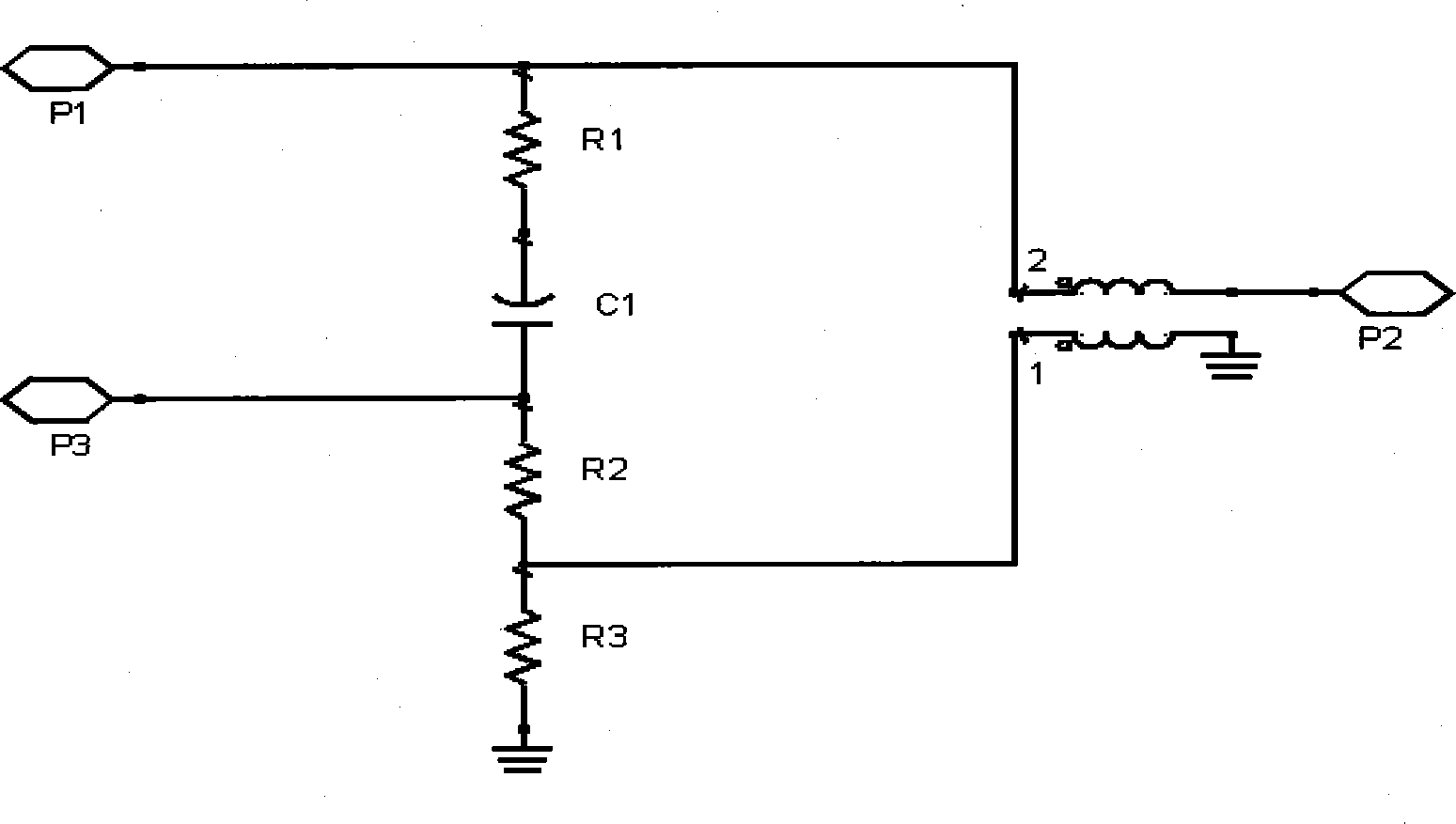

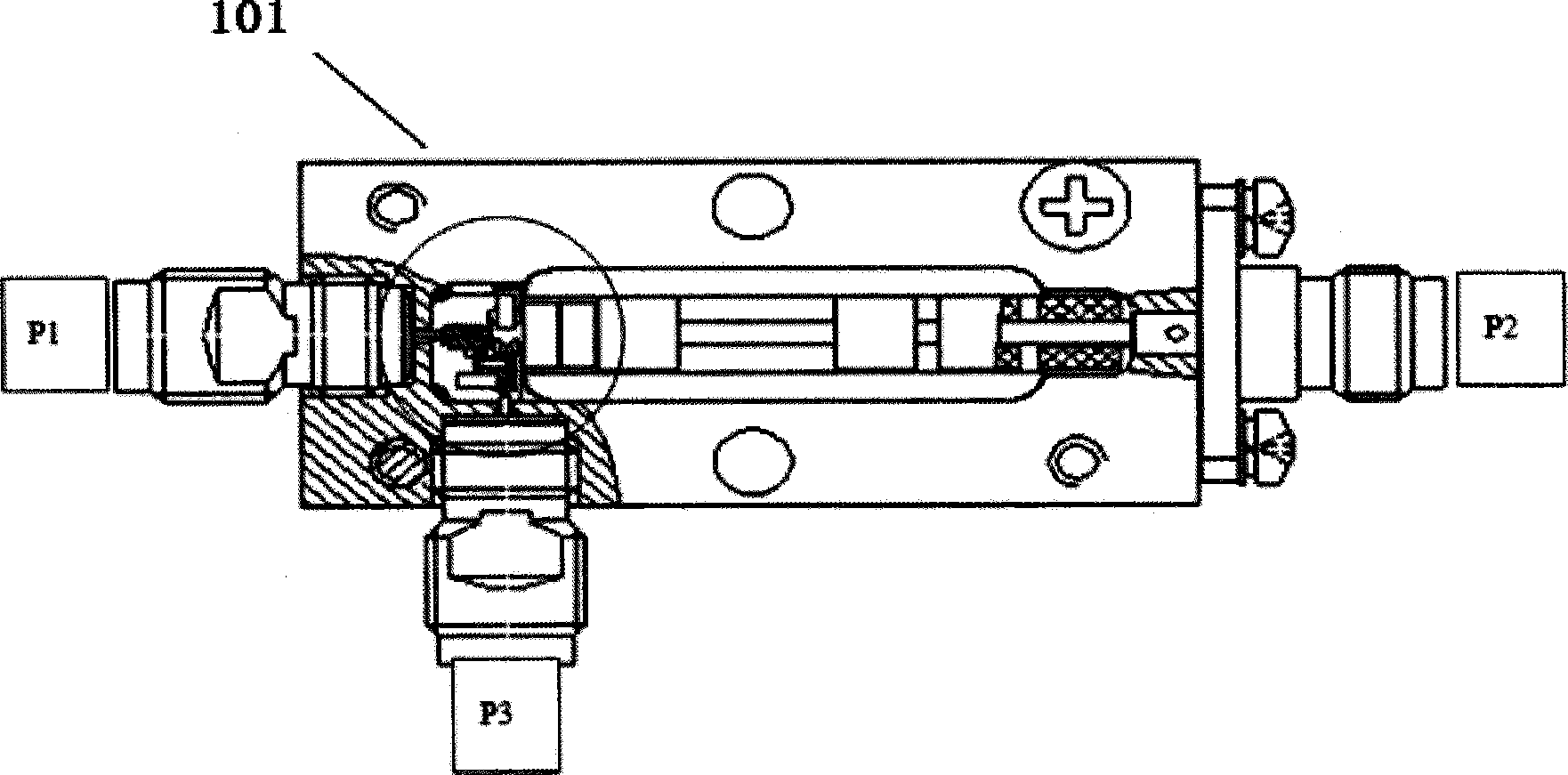

[0019] The present invention provides an ultra-wideband bridge based on a thick film fabrication process, such as figure 2 As shown, it includes a thick-film circuit substrate 101, a coaxial cable, a magnetic core and a capacitor; the ultra-wideband bridge has three external interconnect ports P1, P2, P3, P1 and P3 are two ports connected to the resistance power division circuit. One RF port, P2 is connected to the unbalanced end of the balun; when the signal is transmitted in the forward direction, the P1 port is the input port, after the resistance power division, part of the power is coupled to the P3 port for output, and part of the power is directly output through the P2 port; when the signal is transmitted in the reverse direction At the time, the P2 port is the input port, the signal is converted from unbalanced to balanced by the balun, and two signals of equal amplitude and opposite phase are obtained at the balanced end. To achieve signal isolation, part of the sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com