Automatic clamping apparatus of switch dolly

A switching trolley and automatic clamping technology, applied in the field of switch cabinets, can solve the problems of different structures, can not solve the technical problems of the present application, etc., and achieve the effects of reducing work intensity, improving safety and reliability, and reducing personnel operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

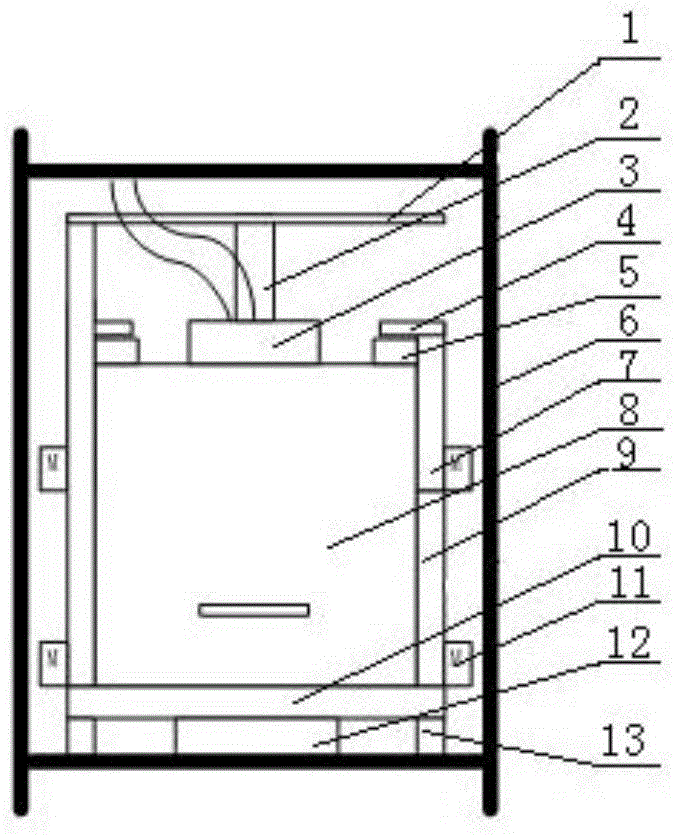

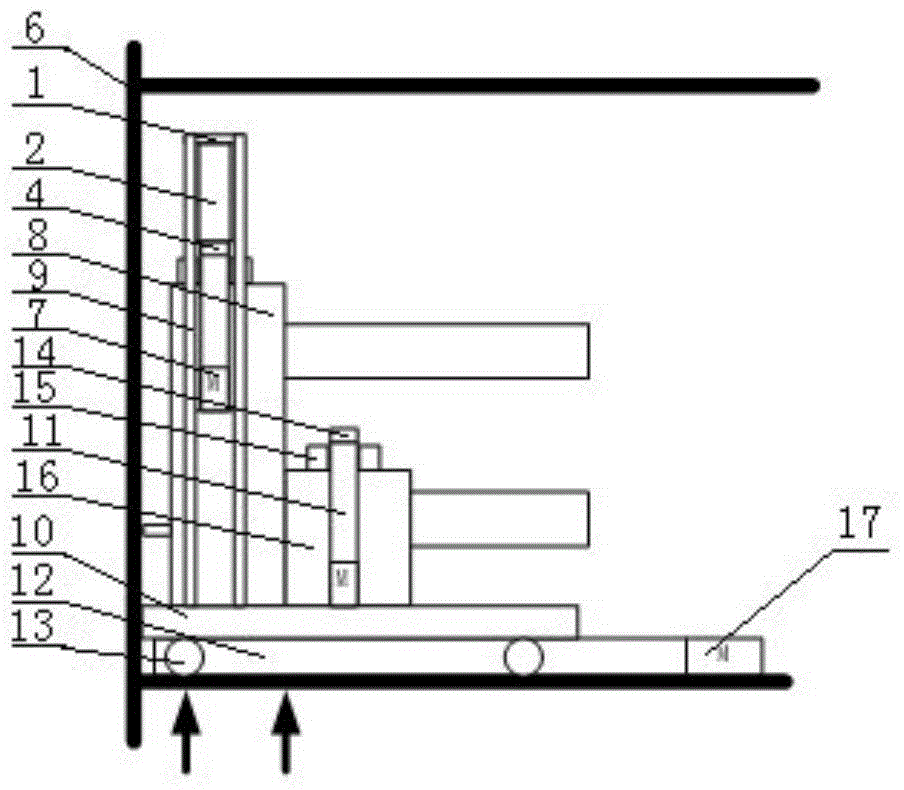

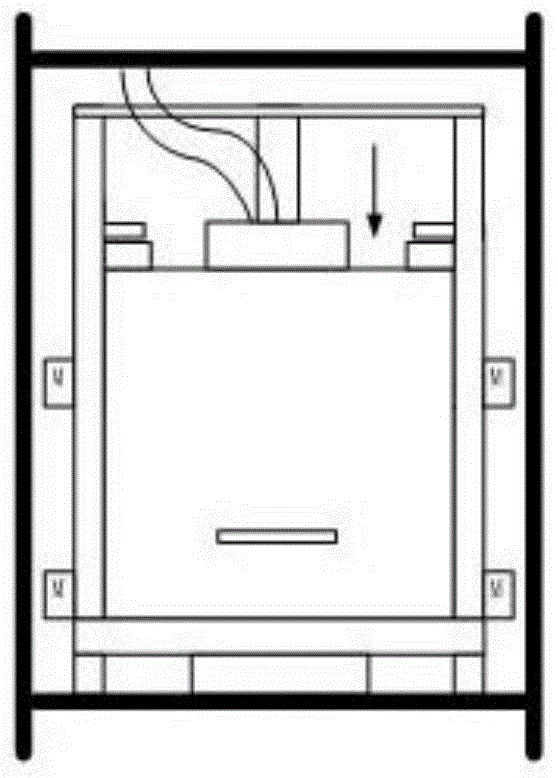

[0018] An automatic clamping device for a switch trolley, comprising a screw slide table 12, a slide table motor, a supporting plate 10, a support frame 9, a push rod motor, a pressure plate and a stopper, fixedly mounted on the bottom surface of the switch trolley installation room 6 of the switch cabinet Threaded mandrel slide table, this threaded mandrel slide table is driven by the slide table motor 17 that is installed in the slide table rear, frequency converter controls. A supporting plate is fixed on the slide table of the screw slide table, a roller 13 is respectively fixed in the four corners of the bottom surface of the supporting plate, a switch trolley 8 is placed on the top surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com