Compound insecticidal composition of cyclofenozide and triflubenzuron

A technology of bistriflubenzuron and an insecticidal composition, which is applied in the directions of insecticides, biocides, animal repellents, etc., can solve problems such as the generation of insecticide resistance, and achieve improved efficacy, increased action sites, The effect of human and animal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Example 1: (18% cyclofenozide bistriflubenzuron EC) 1:5

[0089] Components and content: fenfenozide, 3%; bistrififluben, 15%; emulsifier selected Nongru 500 # Henong milk 601 # , the dosages are 3% and 6% respectively; the solvent is cyclohexanone, 20%, xylene, and the balance.

[0090] The preparation method of the above-mentioned Example 1 is as follows: according to the components and weight percentages provided in the example, the active ingredients chlorfenozide and bistrififluben insecticide are added to the carrier, and surfactants and other Functional additives, just stir and mix evenly in a stirring mixing tank. The stirring and mixing kettle can be enamel reaction kettle, stainless steel stirring kettle, etc.

Embodiment 2

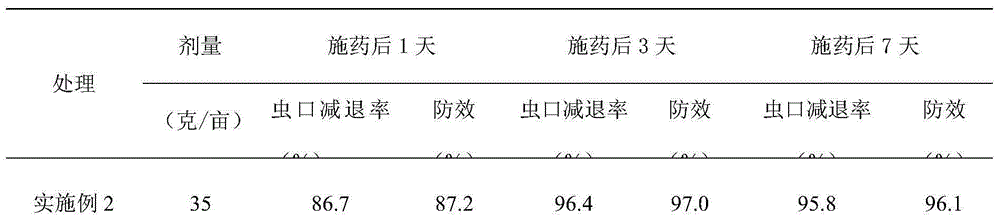

[0091] Example 2: (40% fenfenozide-ditriflubenzuron suspension concentrate) 1:7

[0092] Components and content: cyclofenozide, 5%; diflubenzuron, 35%; emulsifier Nongru OP-10, 2%; dispersant polycarboxylate, 7%; thickener selected xanthan gum , the dosage is respectively 0.1%; antifreeze agent ethylene glycol, 5%; defoamer silicone compound, 0.5%; water, the balance.

[0093] The preparation method of the above-mentioned Example 2 is as follows: according to the components and their weight percentages provided in the example, the active ingredient cyflufenozide, triflubenzuron insecticide, surfactant and other functional auxiliaries are placed in sequence In the reaction kettle, add water and mix evenly, undergo high-speed shearing, wet sanding, and finally filter homogeneously to obtain the product. The main equipment is batching kettle, colloid mill or homogeneous mixer, sand mill.

Embodiment 3

[0094] Example 3: (60% cyclofenozide · bistrififluben wettable powder) 1:5

[0095] Components and content: fenfenozide, 10%; diflubenzuron, 50%; wetting agent sodium lauryl sulfate, 2%; dispersing agent calcium lignosulfonate, 8%; filler white carbon black , 8%, filler kaolin, the balance.

[0096] The preparation method of the above-mentioned Example 3 is: according to the components and their weight percentages provided in the example, adding the active ingredients cyflufenozide and bistrififluben insecticide into the carrier, and adding surfactants and other Functional additives, mixed, and then mixed to obtain wettable powder after jet milling. The main equipment is a mixer and a jet mill.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com