Shaping technology of elastic waistline of waist-surrounding paper diaper

A molding process, the technology of ring waist paper, which is applied in medical science, bandages, absorbent pads, etc., can solve the problems of uncomfortable wearing of babies and achieve the effect of avoiding the cumbersome production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

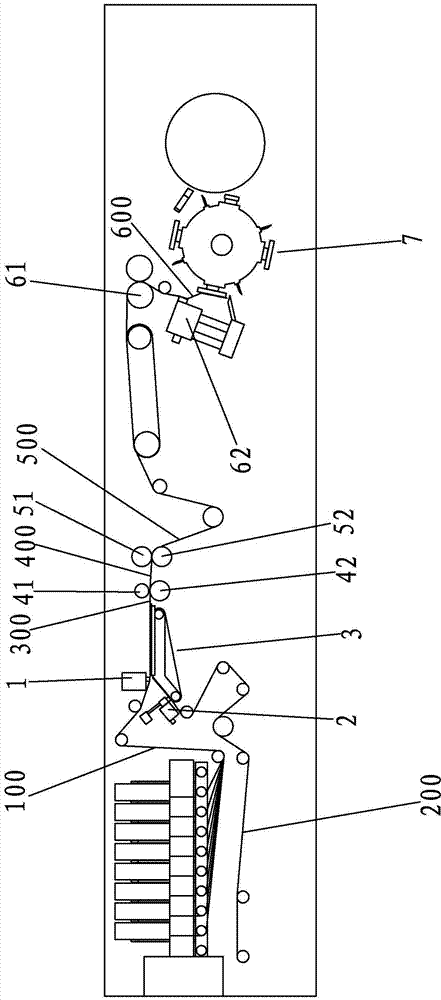

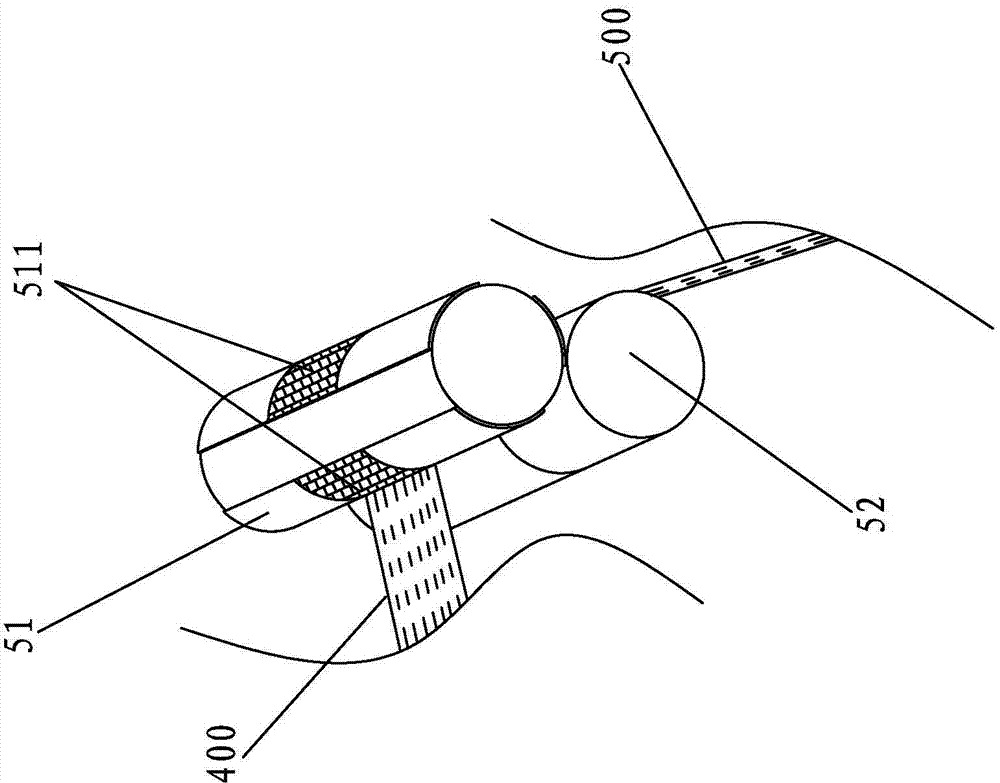

[0021] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

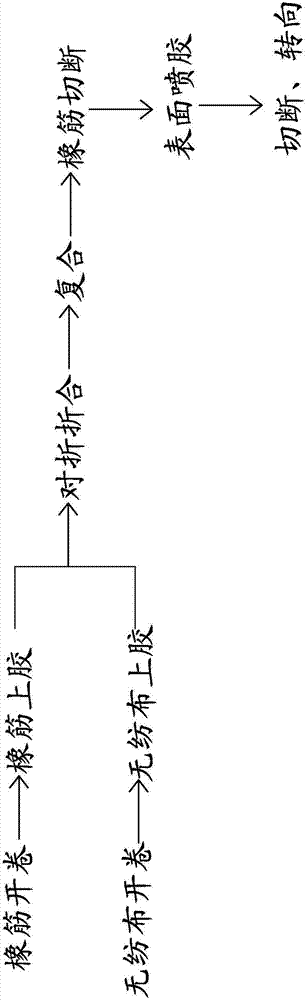

[0022] Such as figure 1 , 2 As shown, the forming process of the elastic waist of a kind of ring-waist diaper of the present invention is realized through the following steps:

[0023] 1) Unwinding of elastic and non-woven fabrics: When unrolling the elastic, pull out the head ends of several elastic rolls, and send out the pulled out elastics side by side at a certain interval, and the pulled out elastics are in the drawn-out position. Above the second half of the spinning cloth;

[0024] 2), rubber bands and non-woven fabrics are glued: glue the surface of each rubber band 100 pulled out in step 1) with glue machine 1, and apply glue to the non-woven fabrics 200 pulled out in step 1) with glue scraping machine 2 Squeeze glue on the back side of the surface;

[0025] 3) Folding in half: the elastic band 100 obtained in step 2) and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com