A paddy field dynamic rapid water absorption forced filter device

A filtration device and paddy field technology, applied in filtration separation, filtration loop, fixed filter element filter, etc., can solve the problem of inability to quickly take water for filtration, and achieve the effect of improving operation efficiency, adjustable water suction flow, and good filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

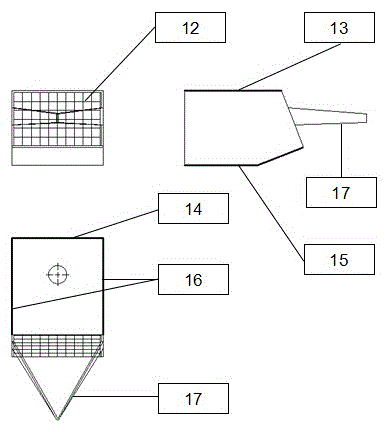

[0019] The solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

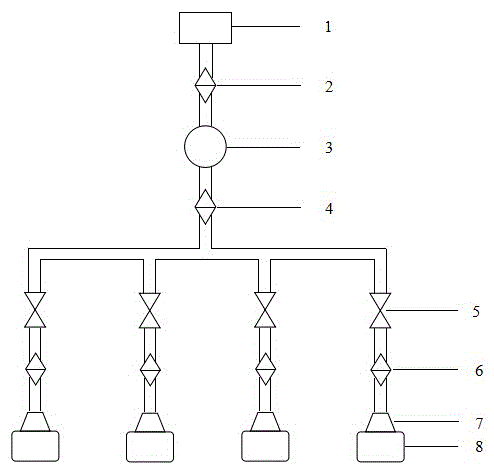

[0020] Such as figure 1 Shown is a schematic diagram of the overall structure of a paddy field dynamic rapid water absorption forced filtration device. The device is composed of a water storage tank 1, a third-stage filter 2, a water pump 3, a secondary filter 4, and multiple parallel water intake branches connected in sequence; each water intake The branches all include switch valve 5 , primary filter 6 , water inlet pipe 7 and sump 8 . According to actual operation needs, the opening and closing state of the on-off valve 5 can be manually adjusted, and then the number of jobs in the water intake branch can be adjusted to avoid waste and insufficient water.

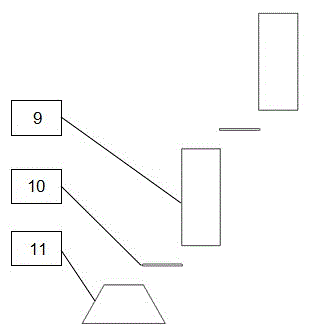

[0021] Such as figure 2 As shown in the schematic diagram of the structure of the water inlet pipe, the water inlet pipe 7 is composed of a multi-section pipeline 9, a plurality of f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com